�

�

Bob Machinist's 1972 Chevron B21 FIA Group 5 Vintage Racecar

� � Owner: Bob Machinist� City: New York, New York

� Model: Chevron B21 (circa 1972)

� Engine: Cosworth YB 2L

� Race prepared by: Vintage Racing Services Inc.�

�

Introduction

��

In the early 1970s, Chevron's B19, B21, and B23 models were prominent in FIA Group 5 racing and in�

European Sports Car Championship events. Chevron's sports cars also appeared in World Sportscar�

Championship events such as the 24 Hours of Le Mans, the 6 Hours of Daytona, and the 12 Hours of Sebring,�

although in those races they were overshadowed by larger displacement machines (e.g. Porsche's 917�

and Ferrari's 512S).�

�

In more recent years, Chevron sports cars have become popular with vintage racers who appreciate�

their balanced and nimble handling as well as their remarkable quickness. Judging by lap times,�

Chevron's open sports cars are among the fastest cars raced at many North American vintage events.�

Depending on the racetrack, these cars may be expected to run as fast as far larger displacement�

Can-Am cars and even later-model GTP cars.�

�

Derek Bennett Engineering Ltd. and their Chevron Racing Cars

��

Derek Bennett was a skilled driver who leveraged a great deal of natural intuition �

to become a leading racecar designer. He started learning the craft in the 1950s by preparing�

stock cars, then by building Midget speedway racers for himself and for friends.�

In 1960 he built a single "Bennett" front engined Formula Junior. After a�

couple years off from racecar construction, Bennett came back to the game and set his sights on�

the "clubman" racing class where he would challenge the Lotus Seven and Mallock U2 establishment.�

Bennett's entry into the clubman scene was immediately successful. In fact, two cars were built�

and between them racked-up twenty-eight race victories in 1965. The success of Derek Bennett's�

two prototypes led to seven orders. Bennett officially went into business as Derek Bennett�

Engineering Ltd., and shortly thereafter came up with the tradename: "Chevron." Those first�

two cars were retrospectively assigned model designation "B1" and the following seven were�

designated "B2".�

�

Lancashire racer (and sometimes farmer) Digby Martland came forward with funding to�

support Bennett's next project: a GT class racecar with Ford Twin Cam engine. Martland's car�

would be designated the Chevron B3 model. Bennett built it with a very basic spaceframe of square�

steel tubing reinforced with a combination of steel and aluminum sheetmetal sheeting�

under a fiberglass body. While testing the B3, Peter Gethin set a new GT lap record at Oulton Park�

in 1966. The B3 clearly had great potential, but Derek Bennett bet its chassis could be even more�

successful with a different engine. He approached BMW and requested support for use of their 1991cc�

four-cylinder engine. By installing the BMW engine with a dry sump lubrication system, he felt he�

could improve reliability enough to make it suitable for racing. Even as a second B3 was being�

constructed, Derek Bennett constructed a B4 alongside it; the essential difference being that the�

B4 chassis had provisions for the BMW engine. From that developmental period, customer cars soon�

followed: seven B6 racecars were built in 1967 (six with BMW engine and one with Ford), then�

44 B8 racecars (34 BMW, seven Ford/Cosworth, two Climax, and one BMC) between 1968 and 1970.�

�

The rules of European sportscar racing changed dramatically for 1969 and again for 1970.�

First came a reduction in required windscreen height. Derek Bennett saw the need to take what�

he'd learned over three years of working with the B4/B6/B8 series and apply it to a new lower�

profile model.�

�

Chassis changes for the new B16 weren't particularly dramatic, but they were extensive. It was�

the bodywork that caught everyone's attention: all-new and jaw-droppingly gorgeous. Against his�

usual instinct of designing everything in-house, Derek Bennett made the unprecedented decision�

to commission Specialised Mouldings' stylist Jim Clark to create an all new body along the lines�

of the Ferrari P4. The resulting body looked right to all critics. �

�

Simultaneously, realizing that the BMW engine was decreasingly competitive Bennett approached�

Keith Duckworth at Cosworth to develop an appropriate engine for two liter racecars. The Formula Two�

spec Cosworth FVA engine only had a displacement of 1598cc, but Keith Duckworth felt that increasing�

its stroke to its practicable limit might make it suitable. The limit proved to be just 1790cc, which�

was well below what class rules would have allowed, but the results were pleasing nonetheless. The new�

Cosworth FVC engine was found to be at least 40hp more powerful than the larger BMW engine it replaced.�

�

Following Chevron tradition the B16 was a winner from its very first race - Brian Redman's B16 dominated�

the 1969 Nürburgring 500km race from start to finish - but the B16 wasn't deemed a totally successful�

design by drivers. Drivers of lesser skill found the car terrifying to drive. As introduced, its bodywork�

was aerodynamically unbalanced and it took a fair amount of development work to get to the root of the�

problem. It was necessary to dramatically increase downforce at the rear to make it right.�

(For a while, drivers were fooled into thinking that the B16 suspension had peculiar transient�

understeer/oversteer problems.)�

�

FIA rules changed again in 1970 even as a new 2-liter Sports Car Championship Series raised�

stakes and expectations. The new Group 5 definition favored open sports cars with perfunctory�

windscreens, and Lola's new T210 model exploited the change. Jo Bonnier's T210 weighed in at�

Paul Ricard for the series' first round 70Kg lighter than Brian Redman's B16, and it had less�

frontal area too. The rule change had made the B16's enclosed body obsolete and it was only through�

valiant effort by Brian Redman and the last minute arrival of a one-off open-top B16 "Spyder" �

that victory in the Manufacturer's Championship was achieved. It came down to the last turn on�

the last lap of the series' last race; the margin of victory was one precious championship point.�

�

For 1971, styling again changed dramatically. Brian Redman's suggestion was to simply mimic the�

wedge-shaped Porsche 908/3. To that end Derek Bennett produced an all-new, open cockpit, lightweight�

body which he draped over a barely changed chassis.�

Thirty-five Chevron B19's were produced. �

�

For 1972 the B19 was only slightly updated to become the Chevron B21. �

Rear upper suspension pick-up points were relocated on the frame.�

The width of the aluminum armrest/divider between driver and passenger seats increased from about 3" to about 5".�

New rules for FIA Group 5 racing emphasized that the cars had to appear as two seaters and thus by�

definition must have full width roll hoops and symmetrical cockpit openings.�

(Tonneau covers over the passenger side weren't permitted.)�

Twenty-eight Chevron B21's were produced.�

�

�

�

The Chevron B19, B21, and B23 feature similar wedge-shaped open sportscar fiberglass bodywork.

�

(Note: the Chevron B19 in the background displays Red Rose livery and Niki Lauda's race number.

�

In May 1971 at the Salzburgring, Niki Lauda won the only race he ever drove a Chevron in.)

�

�

"Even today the B19 stands out in historic racing... Since 1982 I have continued to drive a B19 in American

�

historic races and am constantly amazed by just how good the car is, even in comparison with modern

�

ground-effect cars - proof, if it were needed, of Derek's belief in structural integrity combined with

�

light weight." - Brian Redman, in the forward he wrote for Chevron: the Derek Bennett Story.

�

�

B21 racecars were successful enough in the 1972 European Sports Car series to bring Chevron second�

place honors in the Manufacturers Championship. (Points: Abarth 112, Chevron 109 and Lola 105.) �

Chevron's first victory in the series was scored by Dieter Quester with a BMW-powered B21 at the�

Salzburgring (Austria) on May 21. John Burton won at Montjuïc Park (Spain) with an FVC-powered�

B21 on October 8, and went on to finish second in the Drivers Championship.�

�

�

Chevron's also ran up front in the 2-liter class at FIA World Championship for Makes (a.k.a. the World�

Sportscar Championship) events. Co-drivers John Hine and John Bridges drove their FVC-powered B21 to�

victory at the Spa 1000km race on May 7 and also at the Nürburgring 1000km on May 28.�

Rolf Stommelen and Toine Hezemans won the Austrian 1000km at the Österreichring on June 25�

with their BMW-powered B21. WCM success carried over into the 1973 season, with a notable victory�

by G. Morelli and Mauro Nesti at Vallelunga (Italy) on April 8; they used a 1.6L FVA engine. On May 13,�

Frank McBoden and Luigi Moreschi finished first-in-class and fouth-overall in the Targa Florio. �

�

Jochen Mass and Gerry Birrell dominated South Africa's 1972 Springbok Series with four overall race�

victories plus one 2nd-overall / 1st-in-class finish with their works sponsored Chevron with its�

Brian Hart built Cosworth BDA engine. Derek Bennett designed a lower front suspension for the car to�

take advantage of state of the art Firestone racing slicks. The revised suspension would carry over�

to the new B23 model, so the modified car was known as a "B21/23". �

�

The B23 model represented additional updates for 1973.�

The nose section had a lower profile and provisions for mounting headlights were added, and�

a new rule required bodywork behind the rear wheels to prevent stones from being thrown rearward.�

Twenty-six Chevron B23's were produced.�

�

Car-spotters should be well advised that model identification is complicated by the fact�

that many cars were updated from one specification to another in-period.�

This can be attributed to changing rules and to uneven availability of spare parts following accidents.�

It should also be well noted that cars were supplied to racers for various classes and race series�

around the world,�

Adaptations for those requirements were extremely diverse.�

Chevron's B19, B21 and B23 models particularly excelled in hillclimb competition; and some cars were�

shipped to Italy and to France expressly for that purpose.�

It's not clear how many Chevrons made it to North America during the early 1970s, but SCCA race records�

seem to indicate that at least seven different American drivers entered Chevron B19s in SCCA National races.�

�

�

�

Bob Machinist's Chevron B21 during restoration at Vintage Racing Services in Connecticut (circa 1999.)

�

The car's original steel frame was intact and serviceable, but all aluminum panels needed to be replaced.

�

�

Chevron sports cars feature distinctive frame designs. Derek Bennett favored very simple tubular

�

structures with box tubing at bulkheads, supplemented generously by a combination of steel and

�

aluminum paneling. The tubular structure is especially minimal through the cockpit. After building

�

an initial prototype, Bennett turned over frame production to Arch Motors. Following usual British

�

practice, Arch used mild steel with nickel-bronze filler rod applied using a Calor gas-fluxer.

�

�

Chevron used Duralumin - an aluminum alloy with copper for added strength - for their original tubs.

�

Duralumin is obsolete and difficult to source, so Brian Rechtiene chose to upgrade to 6061-T4. (With

�

T4 heat treatment the alloy is less prone to cracking along small radius bends than the T6 variety.)

�

Brian duplicated the original rivet spacings and the specific combinations of blind and bucked rivets.

�

A modern 3M 2-part adhesive was applied to all joints and was also used to bond aluminum to steel.

�

Vintage Racing the Chevron B21 Since 1999

��

Bob Machinist purchased this Chevron B21 via wire transfer on 18 December 1998 to Pierre Dutoya�

who was represented in negotiations by Ivan Mahe at Equipe Europe, 21 rue du Champs Renard,�

77540 Courpalay, France.�

The purchase included a Cosworth FVA engine which had been removed from the chassis and�

was located in Belgium at the time of the sale, but which was collected and shipped to U.S.A.�

with the chassis.�

�

Bob Machinist started out as a ski racer, and then took up motorcycle racing. In his youth he was offered�

a chance to ride for the Suzuki racing team, and with them he traveled to the Isle of Man. His�

motorcycle racing career was short-lived, but the racing bug never left him. Now much later in his�

career, Bob has been racing cars for many years. From the very beginning of that period, Bob has�

partnered with Kent Bain of Vintage Racing Services for car preparation and for support at the racetrack.�

�

Bob has owned and raced a remarkable variety of racecars - Caldwell D9 Formula Ford,�

the ex-Mark Donohue Elva Courier, the ex-Jim Lenehan Datsun 240Z, Aston Martin DB4 lightweight,�

'72 Camaro, Chevron B39 (1976 vintage F2), March 732 (1973 vintage F2), Triumph TR4A, some GTP�

cars, and many modern Porsches (from 914-6 through 935) - they've all been prepared by VRS. �

�

Of all the cars Bob has raced though, the Chevron B21 is his favorite. He has driven it in about�

150 vintage races.�

�

For racers who are going to campaign a car so actively, engine maintenance costs can become a�

significant concern. Original Cosworth FVA and FVC engines are becoming scarce, and they're relatively�

costly to service. Very shortly after restoration of Bob's B21 began, a decision was made to substitute�

a Cosworth YB engine as used in European-spec Ford Sierra RS Cosworth street cars from 1986-1992.�

One of the earlier engines could, of course, be retrofitted if someone requires an entirely period-correct�

engine specification, but the YB engine is permitted by all the clubs Bob races with.�

�

Now it's time to dramatically cut back on his racing and Bob is obliged to find the Chevron a good home.�

His advice for the next owner: "If you're going to race the Chevron, you really need to commit to at�

least a race weekend a month plus some practice weekends. If you don't drive it frequently, you won't�

stay sharp enough and it might bite you. It's a fast car!" On the other hand, he commented that the�

car is forgiving. "Unlike a ground effects car where you have to get it to a certain speed in order�

for it to work, this car can be driven in a non-aggressive way." Also, since it's a flat bottom car it�

doesn't come un-glued from the ground in the event of a mishap. Did any of the Chevron's performance�

characteristics surprise Bob? "It's a GREAT car in the rain. Perhaps that's something to do�

with its aerodynamics, plus driver visibility is quite good." �

�

Bob's advice of new drivers is to start with an open wheel car in a "momentum" class. Formula Ford�

would be the obvious example. That's where you have to focus on the fundamentals. The focus will keep�

you from developing bad racing habits.�

�

In the Chevron's class, driver experience and track knowledge are hugely important. The level of�

competition is quite high. Remember all those cars Bob has driven? He has been collecting in-car�

camera footage for a long time and he makes active use of it. It really helps. He also takes copious�

notes, and he expects the same of the people who prepare his cars.�

�

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

Features and Specifications (as currently presented)

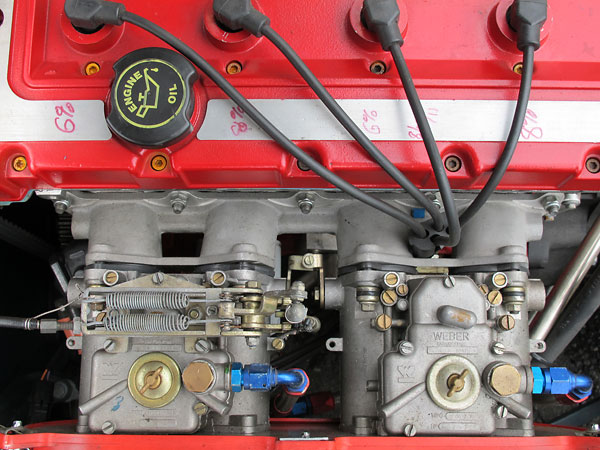

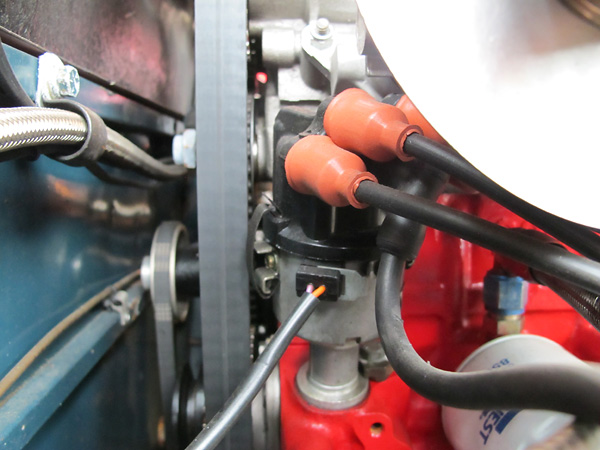

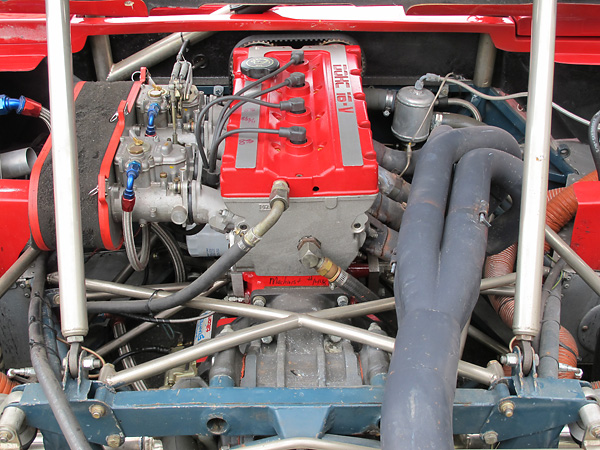

�| Engine: | �Cosworth YB 2.1L 16-valve DOHC, built by Marcovicci-Wenz.�

(~13:1 static compression ratio. 305hp at 8100rpm. 212ft-lbs at 6600rpm. 35 degrees total ignition advance.)�

Carrillo rods.�

Dual Weber 50DCOE carburetors.�

ITG Red Band Megaflow (JC50) foam air filter.�

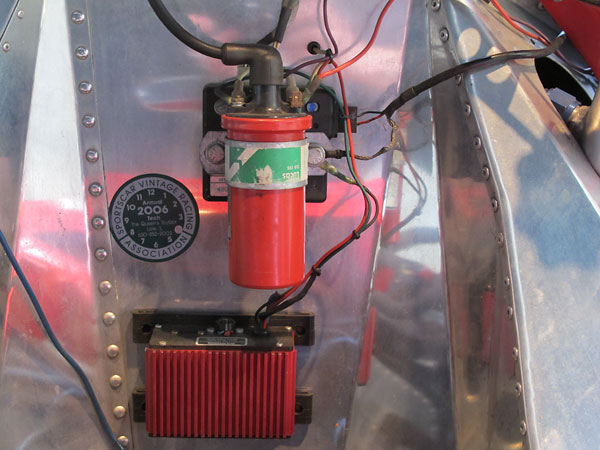

Magneti Marelli distributor.�

Lucas AB14 electronic ignition amplifier (48039A).�

MSD Blaster 2 ignition coil.�

MSD Soft Touch Rev Control (part number 8728).�

TDC / Fast Forward dry sump oil pump.�

Modified engine oil reservoir system (increased to 13 quart capacity). | �

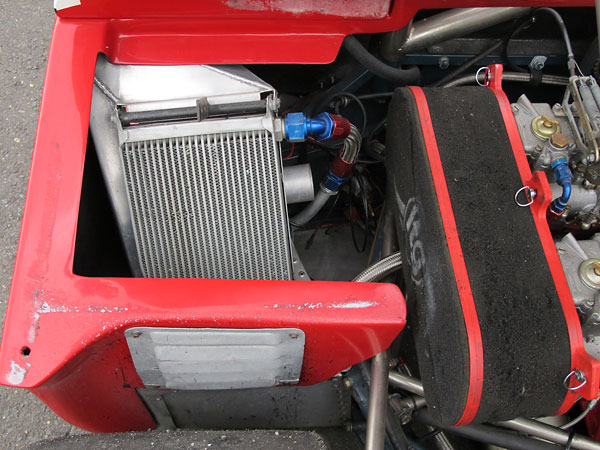

| Cooling: | �stock Chevron copper and brass crossflow radiator.�

Custom fabricated aluminum header tank and swirl pot.�

S.P.A. Cool 25-row aluminum oil cooler. | �

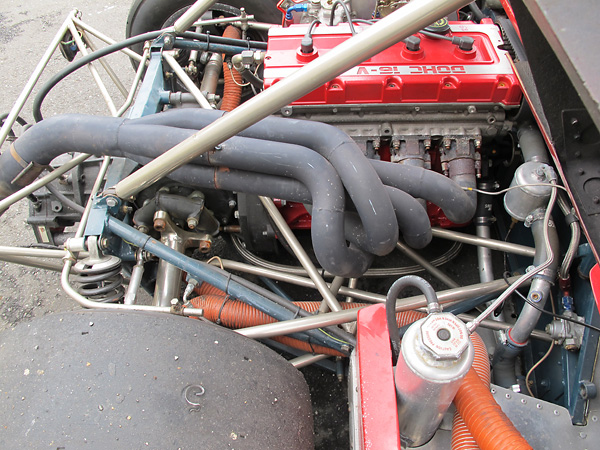

| Exhaust: | �custom fabricated four-into-one header.�

SuperTrapp muffler.�

(Usually races with baffles removed, except at Lime Rock and Roebling Road.) | �

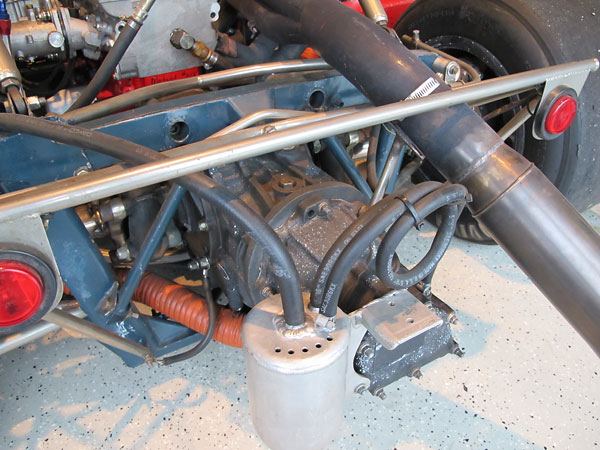

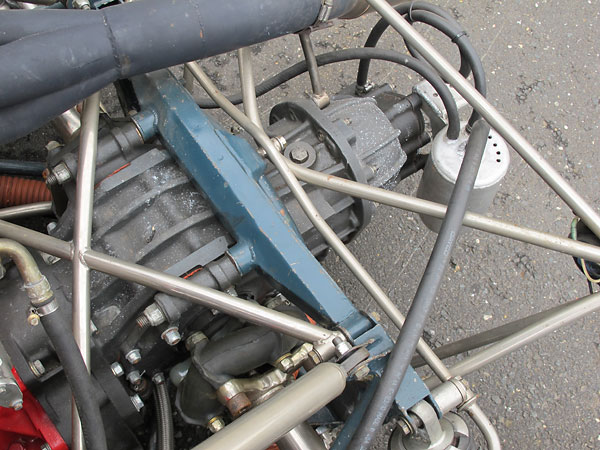

| Transaxle: | �Hewland FT200 five speed.�

Tilton twin-plate 7.25" clutch (7/8" x 20 spline).�

Gear ratios to suit various racetracks.�

9:31 ring and pinion.�

Hewland cam and pawl type limited slip differential. | �

| Basic Dimensions: | �93" wheelbase.�

52" front track.�

52" rear track.�

26.5" total height.�

145" total length.�

66" total width.�

1037# sans engine. | �

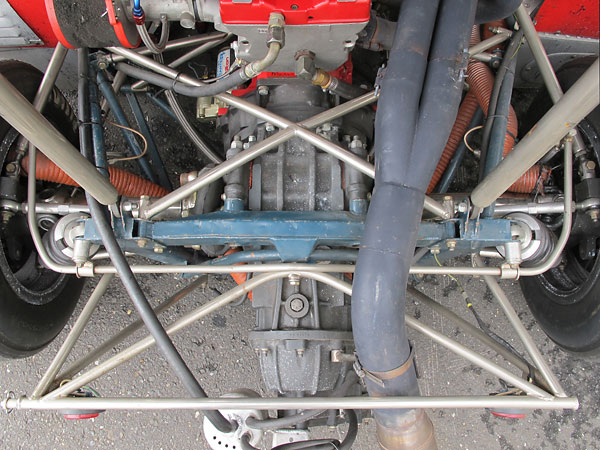

| Front Susp.: | �unequal length wishbones.�

Typically set to 1/16" toe-out, ~0.25 degrees of camber, and no more than ~1.5 degrees of caster.�

Chevron cast magnesium uprights�

KONI aluminum-bodied double-adjustable gas pressurized shock absorbers.�

375#/in, 6" springs. �

Adjustable anti-sway bar.�

Triumph Spitfire steering rack (with exactly two turns, lock to lock). | �

| Rear Susp.: | �inverted lower wishbones, single top links, and twin radius arms.�

Typically set to 1/16" toe-in, no camber, and no more than ~1.5 degrees of caster.�

Chevron cast magnesium uprights�

KONI aluminum-bodied double-adjustable gas pressurized shock absorbers.�

600#/in, 6" springs.�

Adjustable anti-sway bar. | �

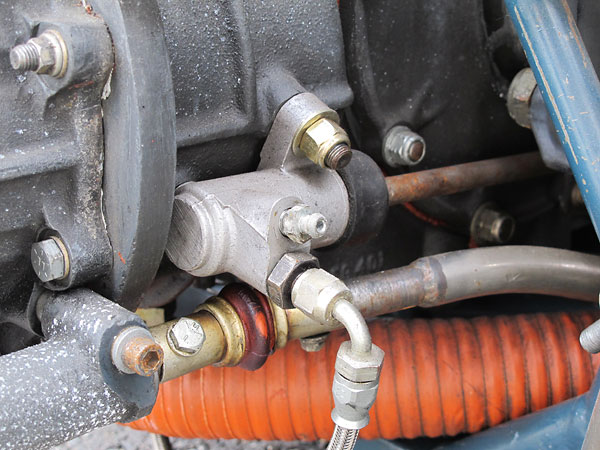

| Brakes: | �(master) dual Girling master cylinders with adjustable bias bar. LMA fluid � (front) Alcon Advantage H-type four piston calipers. 11" vented rotors. � (rear) AP Lockheed four piston calipers. 11" vented rotors. | �

| Wheels/Tires: | �Chevron magnesium wheels (13x10 front, 13x14 rear).�

Avon racing slicks (9.0/20.0-13 front by 13.0/23.0-13 rear). | �

| Electrical: | �PowerSafe SBS HB30 battery.�

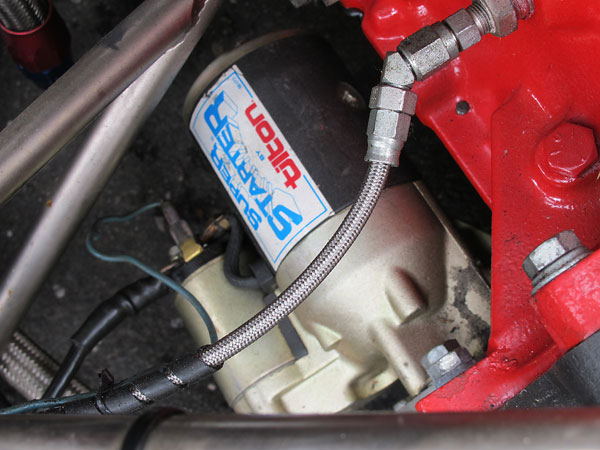

Tilton Super Starter. | �

| Instruments: | �(left to right)�

AutoMeter Sport-Comp Pyrometer EGT gauge (0-1600F),�

RaceTech dual oil pressure (0-100psi) and oil temperature (40-140C) gauge,�

Stack electronic tachometer (0-10500rpm),�

RaceTech water temperature gauge (30-110C). | �

| Fuel System: | �Fuel Safe fuel cell.�

Facet Bendix-type electric fuel pump.�

Holley adjustable fuel pressure regulator. | �

| Safety Eqpmt: | �Sparco six-point cam-lock safety harness.�

Alpha D-shaped ergonomic steering wheel with a SPA Design quick release steering wheel hub.�

SPA Fire Fighter centralized fire suppression system. | �

| Weight: | �~1438# wet. | �

| Racing Class: | �FIA Group 5 | �

Engine Installation

��

�

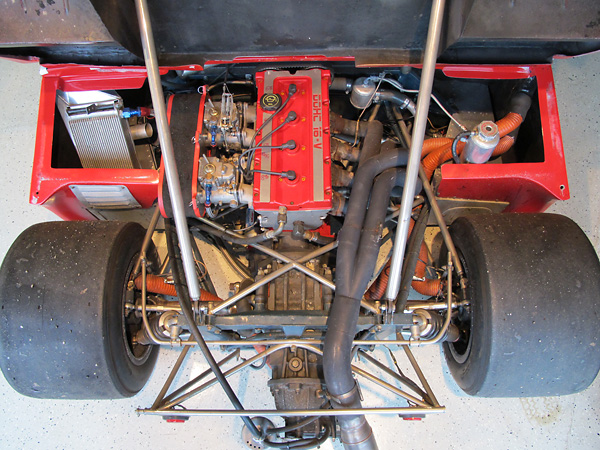

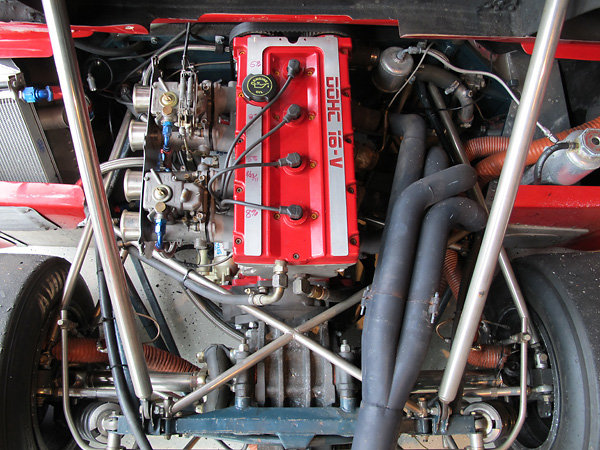

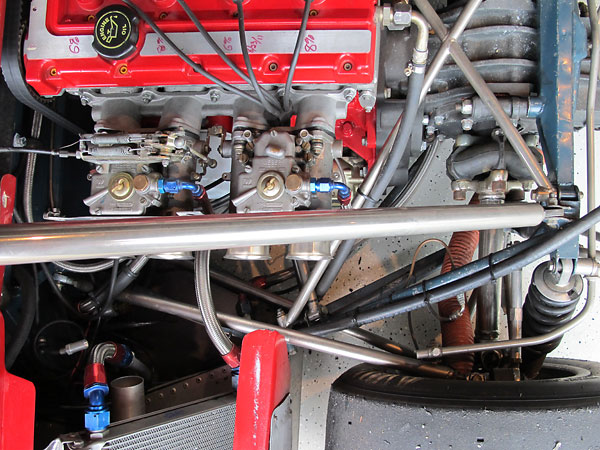

Cosworth YB engine, as used in European-spec Ford Sierra RS Cosworth cars from 1986-1992.

�

This particular Chevron B21 was originally built with a 1598cc Cosworth FVA, but the newer

�

model Cosworth engine is far more practical and economical for vintage racing. An FVA

�

engine (in pieces) came with the car when purchased and it's kept in safe storage.

�

�

One key difference between FVA and YB is that intake and exhaust are flip-flopped side-to-side

�

between the two. Details such as coolant and oil plumbing and also wiring are therefore reversed.

�

�

The Cosworth YB motor goes ~25 hours between being refreshed. (Early on, when Bob ran a more

�

aggressive spec, it was only lasting about 15 hours. The difference only amounted to about 12hp.)

�

In vintage racing you might expect to run ~3.5 hours in a weekend including practice day and

�

an enduro event. Note: the handwritten numbers on the valve cover are leakdown test results.

�

VRS measures and records compression leakdown after every track session and race.

�

�

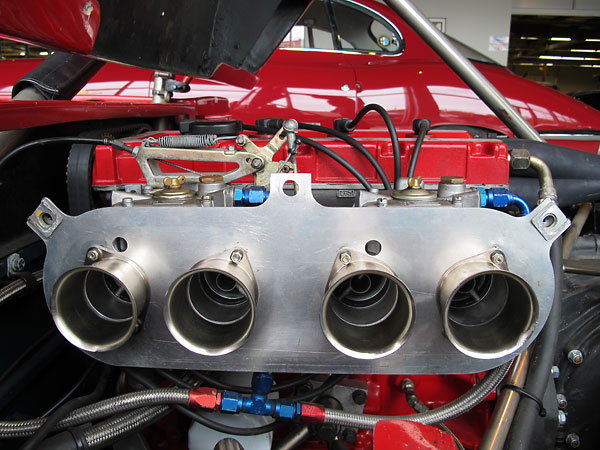

ITG Red Band Megaflow (JC50) foam air filter.

�

�

A two piece plastic structure provides internal support to the foam filter filter element.

�

To function properly, the foam must be lightly coated with oil. The oil traps dust particles.

�

�

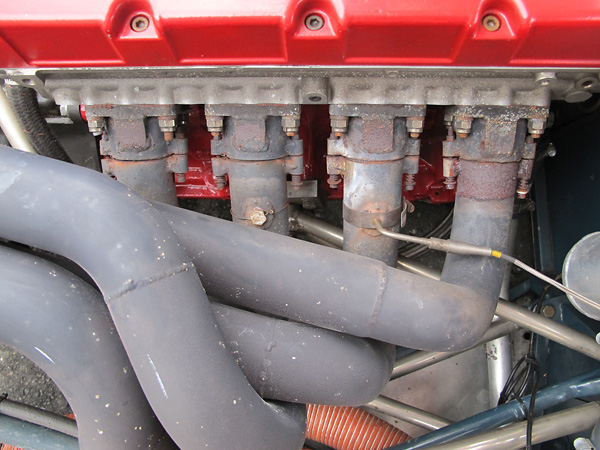

Dual Weber 50DCOE carburetors.

�

�

(Plumbing and cable routing details.)

�

�

Magneti Marelli distributor.

�

�

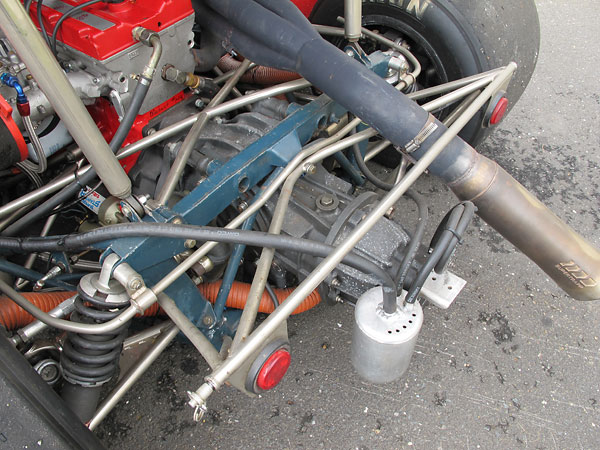

Four-into-one exhaust header custom fabricated in 16 gage mild steel has withstood thirteen years

�

of heavy use. On newer work, VRS has switched over to stainless steel. With either material,

�

they find it's most cost effective to work from pre-bent tubing sections.

�

�

YB engines are notorious for breaking their #3 header tubes due to a harmonic vibration,

�

so Brian Rechtiene put spring-loaded slip joints on all four pipes just outboard of the

�

flanges. Brian uses thicker gauge tubing at the flanges and adds gussets because these

�

features help hold heat. Extra mass there smooths out heat cycling to avert cracking.

�

�

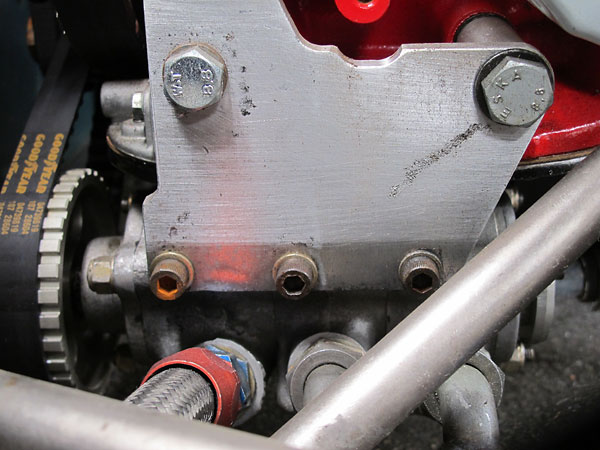

Underneath the Cosworth YB DOHC 16-valve aluminum cylinder head lies a Ford Pinto engine block.

�

�

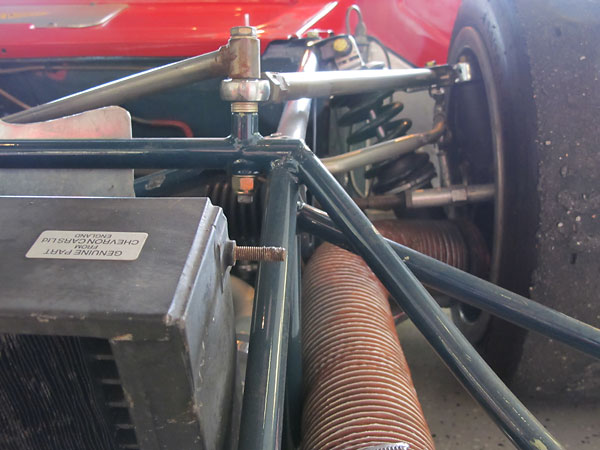

Chevron copper and brass crossflow radiator.

�

�

Genuine Part from Chevron Cars Ltd., England

�

�

Radiator plumbing is currently routed on driver side only because that suits the Cosworth YB engine.

�

The original Chevron B21 design had one pipe on either side, at least for FVC and FVA installations.

�

PowerSafe SBS HB30 sealed lead acid battery is about the same size, shape, and color as the original

�

Varley Red Top battery. In 1972 the car would have used an alternator. One isn't installed now.

�

�

Custom aluminum coolant header tank. (Hoses in background are for brake cooling.)

�

�

Custom aluminum coolant swirl pot.

�

�

An oil cooler is mounted on the left. Originally, it would have been mounted on the right.

�

�

S.P.A. Cool 25-row aluminum oil cooler.

�

�

TDC / Fast Forward three stage dry sump oil pump.

�

�

Tilton Super Starter.

�

�

Bob uses a 9:31 ring and pinion set. Three or four other final drive ratios are available.

�

He also prefers the very robust Hewland "chiclet" (cam and pawl) limited slip differential.

�

�

�

�

| This chart shows what Hewland FT200 gear combinations work best at Bob's most frequently visited racetracks: | ||||||

| Racetrack | 1st gear | 2nd gear | 3rd gear | 4th gear | 5th gear | |

| 1. | Daytona | 13/35 (2.692) | 15/33 (2.200) | 18/30 (1.667) | 21/27 (1.286) | 22/24 (1.091) |

| 2. | Watkins Glen | 13/35 (2.692) | 15/33 (2.200) | 18/30 (1.667) | 21/27 (1.286) | 22/24 (1.091) |

| 3. | Road America | 12/35 (2.917) | 16/30 (1.875) | 18/29 (1.611) | 19/27 (1.421) | 21/26 (1.238) |

| 4. | Lime Rock | 13/34 (2.615) | 14/32 (2.286) | 17/30 (1.765) | 20/28 (1.400) | 22/25 (1.136) |

| 5. | Moroso | 13/35 (2.692) | 16/30 (1.875) | 18/29 (1.611) | 19/27 (1.421) | 22/26 (1.182) |

| 6. | Savanah | 13/35 (2.692) | 17/36 (2.118) | 18/30 (1.667) | 19/27 (1.421) | 19/22 (1.158) |

| 7. | Summit Point | 13/35 (2.692) | 17/36 (2.118) | 18/30 (1.667) | 19/27 (1.421) | 19/22 (1.158) |

| 8. | V.I.R. | 13/35 (2.692) | 17/36 (2.118) | 17/30 (1.765) | 21/27 (1.286) | 22/24 (1.091) |

| 9. | Sebring | 13/35 (2.692) | 16/30 (1.875) | 18/29 (1.611) | 19/27 (1.421) | 22/26 (1.182) |

| 10. | Road Atlanta | 13/35 (2.692) | 15/33 (2.200) | 18/28 (1.556) | 20/27 (1.350) | 22/26 (1.182) |

�

�

Girling clutch slave cylinder. Apex gear shifter universal joint.

�

�

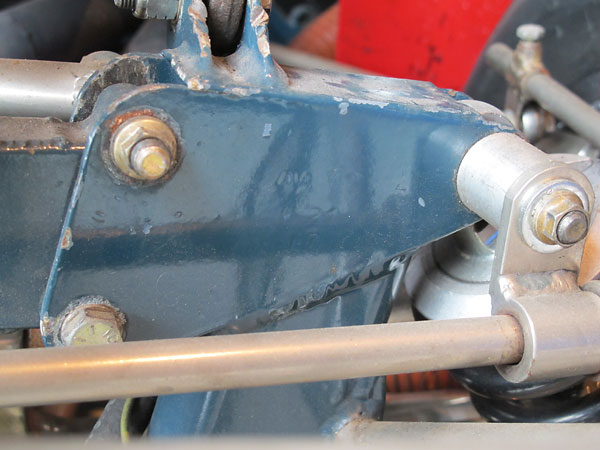

Stamped numbers on the frame, in three rows, appear to read "AM 72", "B 21", and "17". (There's

�

no particular correlation between Arch Motors frame numbers and Chevron serial numbers, but

�

in this particular case it's believed that the frame and car share serial number 17.)

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

Front Suspension

��

�

Triumph Spitfire steering rack. The steering wheel travels exactly two turns from lock to lock.

�

�

The nose frame has been replaced at least once. It's a mild steel fabrication. Back in the day, the

�

joints would have been brazed with an oxy-acetylene torch but the usual method these days is to use

�

silicon bronze filler rod with a TIG welder. The traditional color for Chevron frames is blue (4503N).

�

�

Flexible brake cooling duct.

�

�

To take advantage of newly available Firestone tires, for the 1973 season Derek Bennett redesigned

�

the front suspension. Many B21s were subsequently updated to the later specification.

�

�

Alcon Advantage H-type four piston calipers. Vented rotors.

�

�

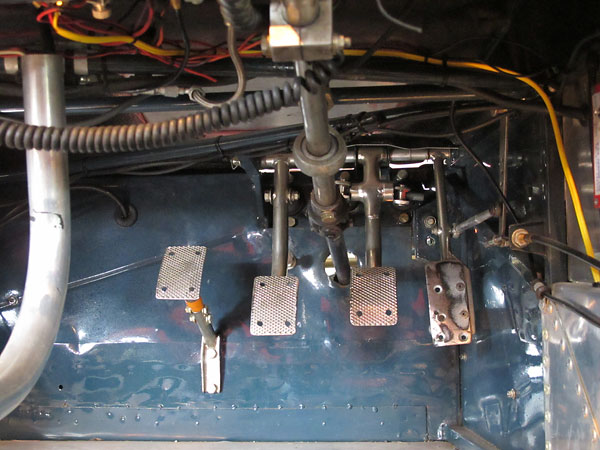

Girling master cylinders for the brakes and clutch. Note that two out of the three cylinders have

�

oversize (five ounce) offset plastic reservoirs. These provide easy fluid level inspection.

�

�

The Lola limp? In contrast with their rivals at Lola, Chevron prioritized driver protection.

�

The Chevron B21 footbox and pedals are set behind the centerline of the front wheels and

�

steel paneling extends all the way around. On the Lola T290, the drivers feet extend out

�

nearly to the front of the tires and the footbox is skinned in lightweight aluminum.

�

�

Rear Suspension

��

�

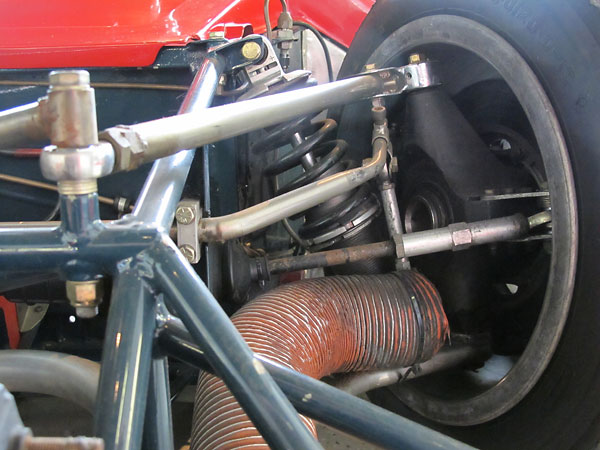

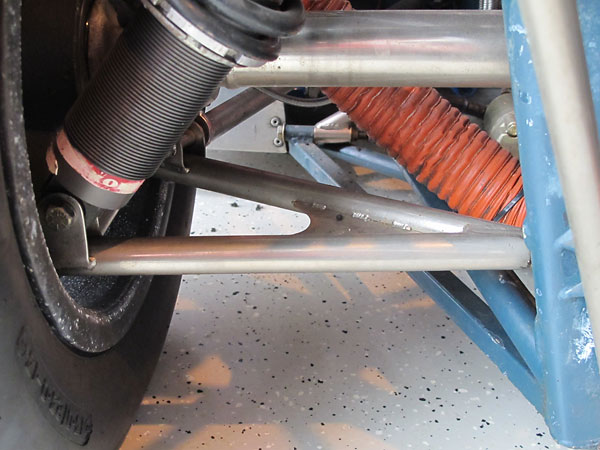

Generally, racetracks are smoother than they were in the past so racers can run stiffer springs.

�

Suspension settings are usually pretty consistant from race to race, although the team certainly

�

raises ride-height for Daytona (due to the track's banking) and for Sebring (due to the track's

�

rough surface.) Actually, they prefer not to run Sebring anymore; it's hard on the equipment.

�

�

This Chevron B21 still uses its original anti-sway bars, both front and rear.

�

�

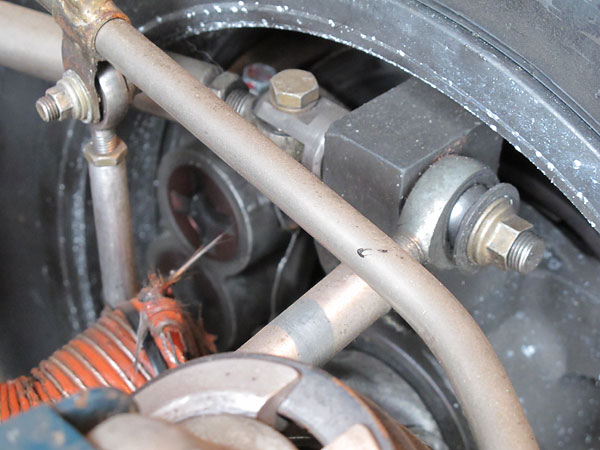

Steel suspension links are nickel plated. Chrome plating isn't used on racecar parts because the

�

plating process can cause cracks to form in welded joints.

�

�

AP Lockheed four piston calipers. Vented rotors.

�

�

KONI aluminum-bodied double-adjustable gas pressurized shock absorbers. (Chevron B21 owners might

�

have used similar KONI shocks back in 1972 except that they wouldn't have been gas-charged.)

�

�

Interestingly, this car has proven much harder on (outboard) universal joints than it has on (inboard)

�

rubber donuts. In fact, U-joints may be the weakest part of the car. It broke two left rear U-joints

�

in just one weekend of racing on the bumpy Sebring circuit one year. The rubber donuts have been

�

perfectly reliable to date, although of course they receive careful and frequent inspection.

�

�

Interior

��

�

Sparco six-point cam-lock safety harness.

�

�

This particular Chevron B21 originally had just one fuel cell and it was mounted behind the seats.

�

That's consistant with the idea that it may have been configured for hillclimb use. Most Chevron B21

�

racecars were set up with multiple fuel cells for long distance endurance races.

�

�

Mounted on the steering wheel: a Racing Electronics brand push-to-talk button, which is part

�

of the 2-way radio system that keeps driver Bob Machinist in contact with his crew.

�

�

During a 4hr endurance race at Daytona, the original Chevron shifter lever broke clean off.

�

Brian Rechtiene's custom heavy-duty shifter ensures the same failure will never happen again.

�

�

Alpha D-shaped ergonomic steering wheel.

�

�

SPA Design quick release steering wheel hub.

�

�

AutoMeter Sport-Comp Pyrometer EGT gauge (0-1600F), RaceTech dual oil pressure and oil

�

temperature gauge, Stack electronic tachometer, and RaceTech water temperature gauge.

�

�

Low oil pressure warning light. (If this comes on, stop the car!)

�

�

A threaded rod inside the brake pedal assembly facilitates minutely shifting a spherical bearing

�

from side to side, thereby precisely altering the distribution of pressure between front and rear

�

circuits. Bob prefers to set this once and forget about it, so there's no remote adjustment knob.

�

�

Armrest/divider between driver and passenger sides of the cockpit increased from about

�

three inches wide on the Chevron B19 to about five inches wide on the Chevron B21.

�

�

MSD Blaster 2 ignition coil, Lucas AB14 electronic ignition amplifier, & MSD Soft Touch rev limiter.

�

�

Pro-Werks fuel filler cap.

�

�

SPA Fire Fighter centralized fire suppression system.

�

�

Exterior

��

�

This racecar is available for purchase through Bob Machinist's agents: Vintage Racing Services Inc.

�

�

Several years ago, Bob Machinist bought out Mike Amalfitano's (Amalfi Racing) Chevron collection.

�

It included a B23, a B29, an ex-Rahal B39, and a staggering collection of wheels and bodywork

�

for Chevron sports racers. Over time, the entire collection will be sold off. Contact Vintage

�

Racing Services if you need parts to service or restore a Chevron racecar.

�

�

Bob Machinist's comments about racetracks for the Chevron B21: Road America is his top pick, although

�

Road Atlanta and Watkins Glen are favorites too. Daytona has traditionally attracted big fields of sports

�

racers, so it's a good experience. Sebring is too hard on equipment. Monterey (Laguna Seca) is his

�

least favorite because events there involve lots of sitting around and much less racing.

�

�

Trust the stopwatch! Getting splitter and suspension dialed-in dramatically improved lap times. The

�

breakthrough realization was that lower isn't always faster; raising ride height a little prevented bumps

�

from upsetting the suspension. Initially the team used aluminum splitters, but had to constantly replace

�

them and at one point a loose splitter cut a tire. JabRock composite splitters wear best but are costly.

�

Now the team favors disposable plywood splitters.

�

�

HSR - Historic Sportscar Racing Ltd. - Rolex Endurance Series

�

�

One of the things that makes the B21 a great racecar is its "feedback loop". From the driver's seat you

�

can see the car's nose very well and judge distances accurately. You can also feel air movement over

�

the car very well, which helps the driver judge speed. When these cars race they can get into tight

�

groups and draft each other with precision, until the driver in the rear slingshots forward to pass.

�

�

Ducts immediately behind the doors feed a strong current of airflow into the oil cooler

�

on one side and into brake cooling ducts on the other side, respectively.

�

�

The doors are held in place by two pins at the front and by a Terry spring clip at the rear.

�

(The pins are set side-by-side, and the door actually hinges downward into place.)

�

�

The inside surface of the door has been cut away to provide an extra large measure of clearance

�

for Bob's shoulders. It's important to Bob that he can get into and out of the car quickly and easily.

�

�

The bottom of Bob's tonneau cover has also been contoured to provide extra shoulder clearance.

�

(We understand that Bob's seat has also been modified somewhat to better protect his ribcage.)

�

Note: tonneau covers aren't traditionally associated with Chevron's B21 model because in 1972

�

the FIA modified Group 5 rules to mandate symmetrical and open cockpits. Tonneau covers would

�

have been used up to that point and would have remained in use anywhere rules permitted them.

�

�

Why so tall? Rear view mirrors are useless if they don't give you a clear rearward view.

�

�

Engine kill switch / battery disconnect switch.

�

�

Most Chevron B21 racecars carry fuel tanks on both sides of the cockpit. This B21 only has a left

�

side tank, but the fuel filler cap is on the right side anyhow. It's connected via a cross-tube

�

similar to the one that would have connected lefthand and righthand fuel cells back in the day.

�

�

Mid-race refueling is necessary when Bob's B21 races in multi-hour enduros. The team discovered

�

that the cross-tube between the filler cap (shown in the previous photo) and the fuel cell slowed

�

refueling. A decision was made to add a second fuel filler cap under the passenger-side door.

�

�

The original engine oil reservoir is in its stock location on the passenger side. It's been cut at

�

the bottom and lengthened to increase system capacity from about ten quarts to about thirteen.

�

�

Stout roll hoop.

�

�

Chevron B21 rear bodywork can quickly and easily be hinged open for service or alternatively it

�

can be removed and set aside for unfettered access to the car's critical mechanical components.

�

�

Collectors Car Garage

�

Distinctive Storage & Convenient Classic Motoring

�

�

First installation of an adjustable rear spoiler on a Chevron B21 is credited to John Boot who prepared

�

John Burton's racecar. It was such an obvious improvement that all the other teams quickly copied it.

�

�

Bob Machinist requested that Vintage Racing Services make a further change: add a Gurney lip to the tip.

�

Bob reports that a 1/4" adjustment of the spoiler adds/subtracts about 5mph at the end of a long straight.

�

�

Chevron magnesium wheels (13x10 front, 13x14 rear).

�

�

Avon tires (9.0/20.0-13 front by 13.0/23.0-13 rear). Typical starting tire pressures: 13psi front, 15psi rear.

�

The tires are typically good for about five hours of racing, before replacement.

�

�

The photos of Bob Machinist's Chevron B21 in action at Watkins Glen and in victory lane at Road Atlanta�

are by Kent Bain, and the three photos of Bob Machinist's Chevron B21 undergoing restoration in 1999�

are by Brian Rechtiene. They're all used here by exclusive permission.�

All other photos are from May 2012, when BritishRaceCar.com visited Vintage Racing Services Inc.�

in Stratford, Connecticut.�

Photos by Curtis Jacobson for www.BritishRaceCar.com, copyright 2012. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Bill Thumel '67 Lola T70 Mk3 | �

| �

Scott Hughes '71 McLaren M8F | �

| �

Walter Davies '78 Lola T492 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�