�

�

Bob Polak's 1969 Mini Marcos, Mark III, Number 73

� � Owner: Bob Polak� City: Cornwall, Ontario

� Model: 1969 Mini Marcos, Mark III¹

� Engine: 1293cc BMC A-series (as used in Mini Cooper S, Mk2)

� Built by: Bill Gilcrease at Mincomp Racing Services�

�

Mini Marcos History

��

The precursor to the Mini Marcos was built in 1964 by professional test pilot and �

amateur aerodynamicist Dizzy Addicott. Addicott foresaw that a BMC Mini could be �

substantially faster if fitted with more streamlined bodywork. He purchased a �

damaged Morris Mini Van, and modified it to prove the point. The body on that first �

prototype was created entirely from steel. It was basically teardrop shaped, but �

with the rear truncated as proscribed by Wunibald Kamm. The front end of the�

prototype was nicely rounded and featured an oval radiator opening, without grille.�

The car came to be known as the DART, which was short for "Dizzy Addicott Racing Team". �

�

The DART prototype captured the interest of Jem Marsh of Marcos Cars. Initially Addicott �

and Marsh planned to work together to industrialize the DART design. The original �

prototype's steel body was used as a plug for making molds, and a handful of �

monocoque fiberglass bodies were subsequently built, but the quality of these early �

bodies was deemed unsatisfactory. The two men had a falling out, and Marsh decided �

that Marcos would create their own Mini-based aerodynamic special. Marcos employees �

Brian Moulton (GRP Manager) and Malcolm Newell (Pattern Maker) are credited with �

styling and design for the new Mini Marcos.�

�

Brian Moulton's personally hand-built prototype debuted in September 1965 at the �

Castle Combe racetrack, where it won its first race decisively. Fitted with a 1293cc �

engine, it lapped the whole 1.6L-class field except for one �

Ginetta G4, and it won by a margin of 82 seconds�

in the ten lap race. Five months later, Marcos was ready to offer the Mini Marcos for �

sale at the annual Racing Car Show at Earl's Court, London. �

�

�

Mini Marcos badge.

�

�

At the Earl's Court show, Jem Marsh made the personal connections that led to a �

Mini Marcos being entered at LeMans later in 1966. The LeMans organizers have �

always been notoriously jingoistic and there was no way they would have let Marcos �

enter their new British "kit car" directly. One must be invited to race at LeMans.�

However, it was felt that they might be persuaded to allow a French team to enter �

the car if it were built-up in France and piloted by French drivers. That was precisely �

how it happened that Jean Louis Marnat, as a privateer, achieved so much with the new �

Mini Marcos. �

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

Marnat's Mini Marcos was the only British car to finish Le Mans in 1966! He finished �

fifteenth overall, and fifth in the 1.3L Prototype class behind four Renault-powered �

Alpines. (Paddy Hopkirk's works Sprite suffered a head gasket failure, and was �

twenty-one laps behind the Mini Marcos when the race was declared over.) This was�

a remarkable finish; the little car demonstrated that it could reach over 130mph on �

the famous Mulsanne Straight, and that it was strong enough to maintain a very high �

average speed over the duration. It was an especially remarkable achievement in �

light of how hurried and how low-budget the car's preparation for the race had been. �

�

After this proof of worthiness, Marcos Cars could hardly be denied an invitation to �

compete at LeMans in 1967. Alas, the factory team was unlucky. They suffered an oil�

pump failure on the eleventh lap and retired from the race. However, their somewhat �

more streamlined Mini Marcos Mark III was clocked at 141 mph on the Mulsanne Straight.�

�

�

MARCOS 1500 - Chassis No. 7104

�

Marcos Cars Ltd., Greenland Mills, Bradford on Avon, Wiltshire, England.

�

(Recommended Oils: Mobil, Shell, BP, Castrol, Esso...)

�

�

�

�

�

�

Bob Polak's Mini Marcos

��

Bob Polak bought Marcos 7104 in January 2007 from Jeremy Bannister of Pennsylvania. �

The car had been imported to U.S.A. in 2002, and it's one of only a handful of �

Mini Marcos cars in North America. �

�

Features and Specifications

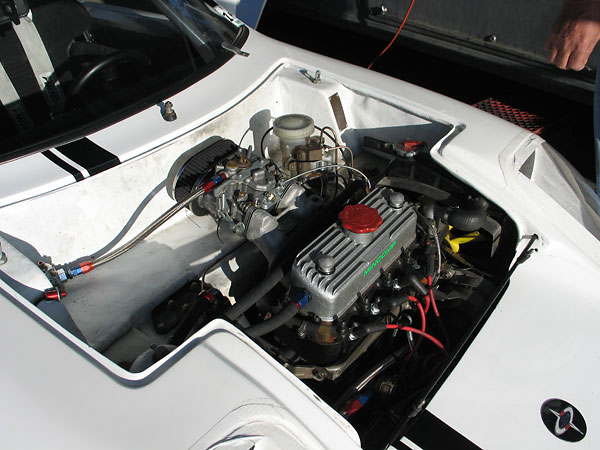

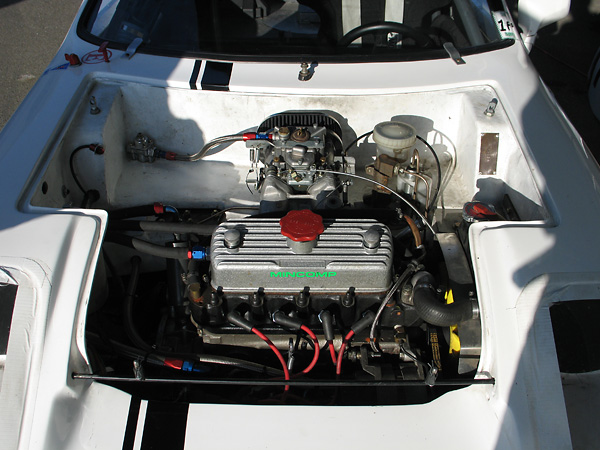

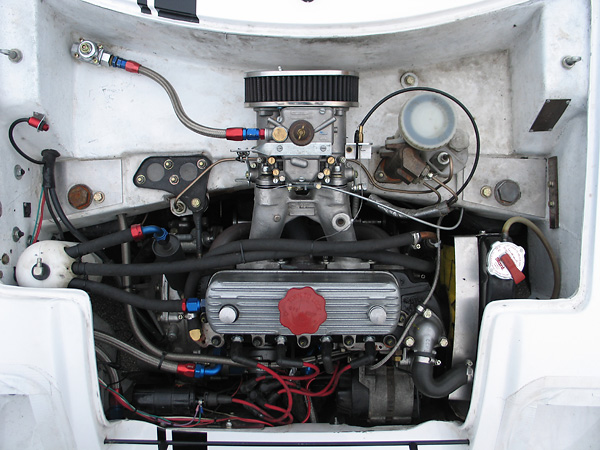

�| Engine: | �1293cc BMC A-series as used in the Mini Cooper range, built with an "A+" block. �

Keith Calver custom built cylinder head. ~11:1 static compression ratio. �

Kent Cams camshaft. Forged 1.5:1 rocker arms. (The engine was built for shifting �

at about 7500rpm.) Weber 45DCOE carburetor on 6" Dellorto (4030) cast aluminum �

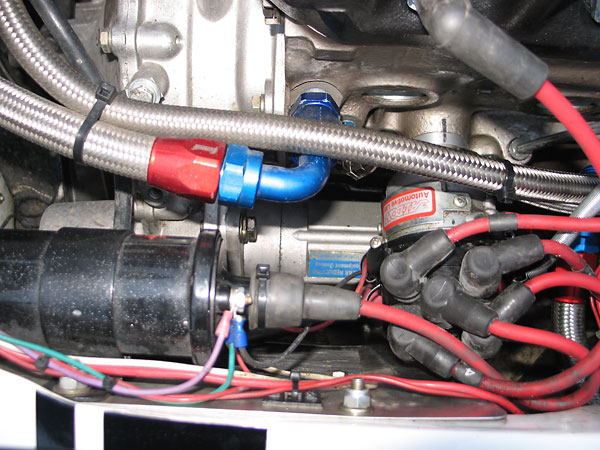

intake manifold. K&N gauze air filter. Aldon Automotive distributor with �

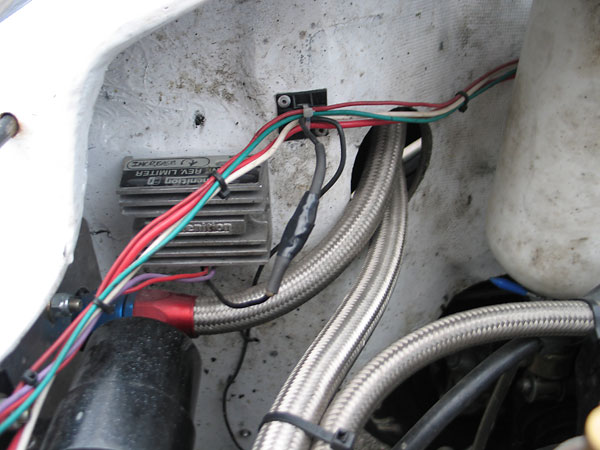

Pertronics Ignitor pick-up. Lumenition adjustable rev limiter. �

Electrically-actuated Accusump system.�

| �

| Cooling: | �Super Two Core radiator and stock Mini Cooper oil cooler. | �

| Exhaust: | �Long Center Branch (LCB) header. Flowmaster two chamber muffler. | �

| Transmission: | �stock 4-speed FWD transmission and clutch system, upgraded with Tran-X �

limited slip differential, Tran-X straight cut transfer gears, �

and 3.9:1 straight cut final drive. | �

| Front Susp.: | �per class requirements, stock Mini Cooper S (Moulton rubber cone) �

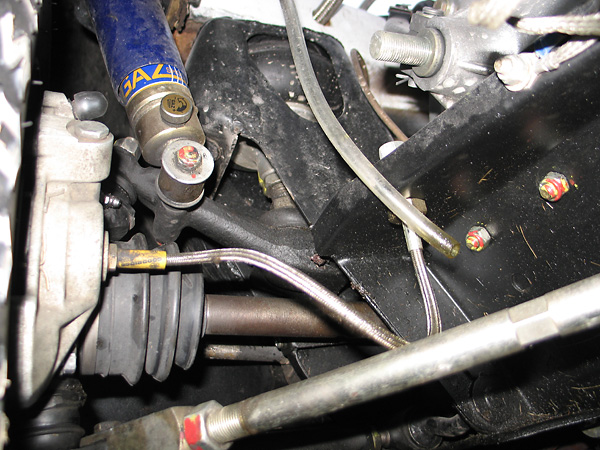

upgraded with negative camber A-arms and GAZ adjustable shock absorbers. | �

| Rear Susp.: | �per class requirements, stock Mini Cooper S (Moulton rubber cone), �

upgraded with GAZ adjustable shock absorbers and a tubular anti sway bar. | �

| Brakes: | �(master) Lockheed dual-circuit master cylinder. Speedway Motors bias valve on rear circuit. � (front) per class requirements, Lockheed Cooper S single piston calipers. � Goodridge braided stainless hoses. Performance Friction (PFC) "01" compound brake pads. � (rear) Mini Cooper S drum brakes. Goodridge braided stainless hoses. | �

| Wheels/Tires: | �Revolution 10" wheels with Hoosier T.D. 165/70 tires. | �

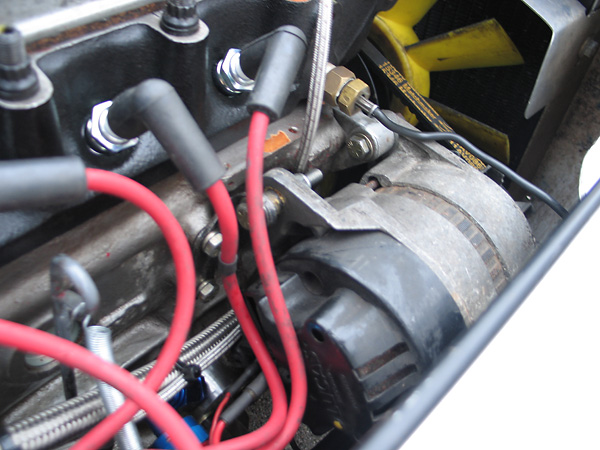

| Electrical: | �Mincomp gear reduction starter. Lucas alternator. Wet cell battery (Group 41 size.) | �

| Instruments: | �(left to right)�

Autometer ProComp coolant temperature gauge (140-280F),�

Autometer ProComp Memory tachometer (0-10,000rpm), �

Autometer ProComp oil pressure gauge (0-100psi), �

Autometer ProComp oil temperature gauge (140-280F). | �

| Fuel System: | �Fuel Safe 6 gallon fuel cell. Facet Blue-top fuel pump. Holley low pressure adjustable regulator. | �

| Safety Eqpmt: | �Ultra Shield Race Products drivers seat. �

Crow Enterprises 5-point latch and link safety harness. M&R mesh window net.�

Mark Williams Enterprises quick release steering wheel hub on a Grant steering wheel.�

SPA "Firefighter" mechanically-actuated, aqueous film forming foam fire suppression system. | �

| Weight: | �1345 pounds with five gallon fuel load. | �

| Completion: | �Construction of this racecar was completed in September 2008, and as �

of September 2009 it had completed twelve races. | �

| Racing Class: | �SVRA "1FP" (F-Production) | �

Engine Installation

��

�

BMC A-series engine as used in classic Minis. This one displaces 1293cc.

�

�

Engine prepared by: Bill Gilcrease at Mincomp Racing Services.

�

�

The Mini Marcos came with a front-mounted radiator, whereas regular Minis had side-mounted radiators.

�

This particular Mini Marcos has the radiator side-mounted to meet the letter of the SVRA class rules.

�

However, on a stock Mini the radiator mounts to the engine whereas this radiator is mounted to the body.

�

�

Aldon Automotive distributor with Pertronics Ignitor pick-up. Mincomp gear reduction starter.

�

�

Lucas alternator.

�

�

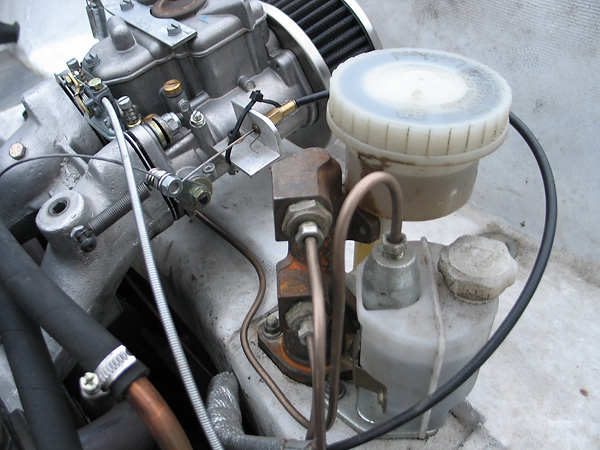

Weber DCOE carburetor on 6" Dellorto (4030) cast aluminum manifold, fitted with K&N gauze air filter.

�

�

Lockheed dual-circuit iron brake master cylinder and Lockheed aluminum clutch master cylinder.

�

Note also that a choke cable has been installed.

�

�

This is a stock Mini oil separator, except with a "dash 8" fitting installed for the breather plumbing.

�

�

Lumenition adjustable rev limiter.

�

�

Suspension

��

�

Stock Mini Cooper S (Moulton rubber cone) suspension, upgraded with adjustable negative camber A-arms.

�

�

GAZ adjustable front shock absorbers. Note that no front anti-sway bar is deemed necessary.

�

�

Mini Marcos cars utilize stock Mini front and rear subframes.

�

�

GAZ adjustable rear shock absorbers.

�

�

The aluminum fuel cell housing protrudes through the floor of the spare tire well.

�

�

Tubular rear anti-sway bar.

�

�

Interior

��

�

�

�

(left to right) Autometer ProComp coolant temperature gauge (140-280F), Memory tachometer (0-10,000rpm),

�

oil pressure gauge (0-100psi), and oil temperature gauge (140-280F).

�

�

(The blue corrugated tubing was part of an experimental ventilation system.)

�

�

Mini Marcos dash plaque.

�

�

Grant steering wheel.

�

�

Mark Williams Enterprises splined quick release steering wheel hub bolts directly to the Grant steering wheel.

�

�

The small print on the knob reads: "Morris" (above) and "Mini-Minor" (below).

�

The Morris logo shows an ox crossing a stream, because Morris was originally based in Oxford.

�

�

SPA Firefighter mechanically-actuated, aqueous film forming foam fire suppression system.

�

�

Accusump pressurized oil reservoir. (Provisions for safely mounting a passenger seat have also been included.)

�

�

Ultra Shield Race Products drivers seat.

�

�

Crow Enterprises 5-point latch and link safety harness.

�

�

Roll cage construction details.

�

�

Right foreground: fire suppression system nozzle.

�

�

Left: Attwood "Sea Guard" marine battery case.

�

�

Fuel Safe 6 gallon fuel cell, installed in a custom aluminum canister.

�

�

Fiberglass body.

�

�

Bob Polak, Number 73.

�

�

Rollcage: well braced against encroachment from the side.

�

�

M&R mesh window net.

�

�

Door pocket and latch assembly.

�

�

Side view mirror.

�

�

Dzus quarter-turn fasteners retain the elegantly simple removable polycarbonate side vents.

�

�

Only one Dzus clip per side!

�

�

Exterior

��

�

Mini Marcos (with a whole lot of negative camber!)

�

�

This little giant killer eats Spitfires for breakfast.

�

�

What an irresistible, cheeky little runt!

�

�

A recessed fuel filler was first introduced with the "Mk3" cars. Wheel opening shape also changed.

�

The standard rear window didn't open, but a hinged rear hatch became optional later in the build.

�

The rear window is actually more curved than it appears in this photo. (It's glass instead of plastic.)

�

�

Fightin' words: "V8 is a vegetable drink. Four cylinders rock."

�

Note also the LED tail lights.

�

�

British bulldog inspired styling?

�

�

Emergency kill and fire suppression switches.

�

�

"In memory of Mary Wollesen, #19 GT5"

�

�

Revolution 10" wheels. Hoosier T.D. 165/70 tires.

�

�

The stock, bolt-on Mini fender flairs were a late addition, installed to satisfy SVRA's technical inspector.

�

�

U.S. Vintage Grand Prix, September 2009: shown here in the pre-grid, Bob's best lap of the Watkins Glen

�

circuit was 2:35.074 and he finished eleventh of thirty-three entries. He was also honored with the

�

Optima Battery Award for sportsmanship in this race.

�

| Notes: | |||||||

| (1) | �

It's difficult to precisely differentiate between a Mark II and a Mark III body.�

Their production dates seem to overlap, but certainly Mark II production started �

near the beginning of 1967 and Mark III production ended around the end of 1970.�

The original company, Marcos Cars, declared bankruptcy in 1971. Production of Mini �

Marcos bodies resumed under three subsequent companies. Mark IV production was from �

1974 to 1981, Mark V production was from 1991 to 1996, and Mark VI production �

started in 2005. Even while Marcos Cars was in business, some Mini Marcos bodies �

were built under license by small companies outside of England. Marcos Cars primarily�

offered Mini Marcos bodies in kit-car form, but they also built up and sold a few �

complete cars. It seems impossible to determine exactly how many Mini Marcos bodies �

were produced in total, and it's certainly impossible to determine how many of the�

kits were completed by their respective buyers. The total seems to be in the �

ballpark of 1300 cars.�

� | ||||||

�

All photos shown here are from September 2009 when we viewed the car at The US Vintage Grand �

Prix at Watkins Glen. All photos by Curtis Jacobson for BritishRaceCar.com, copyright 2009. �

All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Andy Seward 1962 Marcos GT | �

| �

Vic Schuster 1965 Turner MkIII | �

| �

Rachel Nelson 1965 Cooper S | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�