�

�

�

Jim Johnson's 1972 March 729 Formula Ford Race Car

� � Owner: Jim Johnson� City: Woodinville, Washington

� Model: 1972 March 729

� Engine: Ford 1600cc four cylinder

� Race prepared by: owner.�

�

March Engineering Limited

��

At the youthful age of 26 years, Robin Herd resigned from a safe career at National Gas Turbines and�

joined McLaren as Chief Designer, where he would work on Formula One and Can-Am cars just as�

McLaren was becoming a leading player. Somehow though, McLaren didn't keep Herd busy enough,�

and he made time for occasional side projects designing this and that for other racing outfits. He�

dreamed of really focusing his considerable talents on designing Formula One cars. By 1969, Herd�

was looking to move on and was exploring possibilities with an old school chum named Alan Rees�

who had managed Winkelmann Racing in close association with Lotus. Rees brought along another�

friend with automotive parts production experience, by the name of Graham Coaker. Rees imagined�

managing a Formula One team; Coaker dreamed of managing the construction of racecars. At about�

the same time, while working on a design modification to Piers Courage's Tasman Series car, Robin�

became reacquainted with an old Oxford classmate named Max Mosley. Mosley was a barrister�

turned serious-amateur driver. (He had the advantage of a moneyed background.) Mosley dreamed�

about all the fun he could have arranging sponsorships and business deals. One thing led to another,�

and before long Mosley, Alan Rees, Coaker and Herd merged their names and became "March".�

�

March called their first car the "693". Their model numbering system was simple enough to understand:�

it was a Formula Three car for the 1969 season. Construction of the 693 began in Graham Coaker's�

shed before any sort of contracts were signed. By the time the young company moved into a�

3000 square foot unit at an industrial estate in Bicester (a market town near Oxford and also Silverstone)�

the team principals were already making plans for a March 701.�

�

March's 693 made its racing debut in the Lincolnshire International Formula Three race at Cadwell Park�

on September 28. Ronnie Peterson drove it to a third place finish. When the race report appeared in�

Autosport magazine, Peterson's result was blown up into a huge announcement: a top flight car constructor�

had appeared from nowhere, and would be dominating Formula One by the following season. Oh,�

and by the way, they're ready to sell you whatever car you need to be a successful racer too.�

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

March Racecars for the Junior Formulae

��

The March 693 made exactly three race appearances, and its best finish was its first one.�

Few people remember the car, but records show that it featured a square-tube spaceframe chassis�

and quite a few components taken off of a Brabham F3 car. March's 693 was the first spaceframe car�

Robin Herd had ever designed. It was a prototype in the literal sense, and many of its parts were�

fabricated before they were drawn on paper. Its success was not the result of testing and development.�

Put another way: Ronnie Peterson was a ringer, who probably made the 693 look a lot better than it�

was. However, on the strength of Peterson's performance March sold sixteen Formula Three cars in�

advance of the 1970 season. �

�

In 1970, Formula Ford racecars still looked a lot like Formula Three cars, minus wings. "Fords" used far�

less highly tuned engines (making back some of the performance difference with displacement) and�

they rolled on tall, skinny, radial street tires. It was easy for March to accept orders for Formula Fords,�

so they did. March records show that they built ten Formula Fords for the 1970 season: eight for the�

home market plus two for North America. March's Fiberglass bodies were subcontracted to Specialized�

Mouldings, who supplied most of the market. Their "cigar shape" was hardly what you would call�

distinctive.�

�

For 1971, March began constructing a second version of their Formula Three car, with a new full�

monocoque chassis design. Twenty March 713 Formula Three cars were built, nine with spaceframes�

and eleven of the new monocoque model. With introduction of the new chassis, March also introduced�

much fresher looking bodywork. Chisel styling was then in vogue, and March went with it. The new�

bodystyle would eventually carry over to Formula Ford too, but first March built a final handful�

of cars with cigar-nose styling.¹�

�

March's interest in the junior Formulae was rapidly waning. More expensive cars brought a better return�

on capital employed. Although twenty monocoque 723 Formula Three cars were built, the spaceframe�

version was discontinued as was the home market Formula Ford. To continue supplying Formula Fords�

for the North American market, March contracted with Mitchell Engineering, who ultimately built fourteen�

additional March Formula Fords. Our article features the very last car of the series.�

�

�

�

�

�

March's California Connection: Mitchell Engineering

��

Wayne Mitchell completed an apprenticeship in a machine shop and an engineering degree before�

moving to England to pursue his youthful dreams: he wanted to be a professional racecar driver.�

For three seasons he battled in England's (1000cc) Formula Three class against the likes of Emerson�

Fittipaldi and James Hunt. During these three years, he got to know all the founding members of March.�

He was a little bit younger than the others, and especially close friends with March's first paid employee:�

Bill Stone, who had also driven Formula Three cars.�

�

In October of 1969, as Mitchell's money was starting to run out and after he had met and started getting�

serious with his future wife, Mitchell decided he'd soon have to move back across the pond. He met�

for dinner and drinks with Bill Stone, who told him: "I want to show you something before you leave,�

but you can't tell anybody." They left the restaurant and headed to Graham Coaker's house, where�

Wayne was one of the first people to preview 693's chassis as it was coming together. In fact, Wayne�

would lend parts from his own Brabham BT21 to the March founders so they could complete 693.�

Specifically, he recalls lending them rear uprights, drive flanges, and a steering rack.�

�

�

Fast forward to late 1970. Wayne Mitchell has moved - not home to Manitoba but instead to sunny�

Southern California. Old friend Bill Stone has traveled to New Zealand and is returning to London�

with a layover in Los Angeles. Stone looks up his old friend, they get together for some beers,�

and Mitchell shows Stone the fabrication and machine shop he's set up near San Diego. This friendly�

visit inadvertently laid groundwork for the outsourcing of March's Formula Ford model. Why outsource?�

In the early seventies, Formula Ford seemed to be growing faster in U.S.A. than in England. Meanwhile,�

March was up to its eyeballs in work and Formula Fords were far from their top priority. �

�

Mitchell Engineering agreed to build March branded Formula Fords. March handled sales and marketing.�

Mitchell drop-shipped to customers. Many basic components were supplied from March's UK facility,�

including Ford "Kent" engines, Hewland transaxles, front and rear uprights, Girling brake components,�

Smiths tachometers, and custom-made foam-filled rubber fuel cells. March never provided any frames�

or bodies; those were made by Wayne Mitchell to March's drawings. In some cases, such as radiators�

and exhaust headers, March provided sample parts and Mitchell found local suppliers to duplicate them.�

�

Mitchell Engineering built fourteen cars: nominally seven for 1971 and seven for 1972. As Wayne�

Mitchell explained to me: "There is absolutely no difference between a 719 and 729." From his point�

of view the only distinction is when they were sold, not when they were built. March's U.S. headquarters�

in New Jersey sold eleven Formula Fords. In mid-1972, when crates started to back up on Mitchell�

Engineering's shipping dock, Wayne Mitchell sold the last three March 729 cars to local California�

customers. None of the U.S.-built March Formula Fords were shipped back to England. �

�

�

�

March Engineering Limited / Chassis Number 729/7

�

(U.K. constructed March racecars have blue chassis plates. Mitchell Engineering built Marchs have green ones.)

�

�

One small but interesting difference between U.K. produced March cars and the cars Mitchell Engineering�

built under contract is that the U.S. cars have green badges. Wayne Mitchell recalls making this choice as�

he was standing at the counter of the shop who would make them. Asked about color, he answered:�

"The color of money!"�

�

I asked Wayne to retrospectively analyze the March design. What were its strengths and weaknesses?�

Firstly, in Wayne's opinion the car's wedge-shaped nose was a giant mistake because it caused lift.�

The leading edge needed to be much closer to the ground. Secondly, the cars left Wayne's shop�

with bog-standard engines. Especially in California, there was a lot of cheating going on in Formula�

Ford. Stock engines were completely uncompetitive. Wayne felt the car's should have been offered�

with some sort of specially prepared engines so they'd at least have a chance. Thirdly, March didn't�

seed the market by getting a car into the hands of a really good driver. Had one hot shoe driver shown�

the car's potential, sales might have come easier and other good drivers might have won their own�

races. The car may have been a couple pounds heavy, but only a couple. Wayne remembers it�

as a good solid design, easily tunable and with a lot more potential than was demonstrated on track.�

�

The old saying goes "What wins on Sunday sells on Monday." There's a flip side to that coin.�

Unfortunately, Formula Ford production didn't turn out to be as lucrative as Mitchell hoped. He had a�

payroll to meet, and the vagaries of racecar sales made him uncomfortable. For that reason, Mitchell�

chose to focus on building up his machine shop. Nonetheless, in the thirty years since parting ways�

with March, Wayne Mitchell has never gotten away from racing. For example, Wayne Mitchell currently�

serves as tech inspector for two racing clubs: VARA and HSR-West. Mitchell Engineering has long�

been a favored supplier for specific precision racing parts including for example dog rings for racing�

gearboxes.�

�

Only a handful of spaceframe March racecars still exist, but Jim Johnson managed to save the last�

one - 729 number seven - from oblivion. He discovered and purchased it as a basket case,�

and has been able to document its provenance and complete its meticulous restoration with the help�

of Wayne Mitchell. Although U.K. records are sketchy, Mitchell has testified that Johnson's 729 is�

authentic: the last of a rare breed, beautifully presented and quicker than ever.�

�

�

IMPORTANT ANNOUNCEMENT

�

BritishRaceCar.com will have to cut back plans for continued growth if we can't find more financial support.

�

If you like what you've found here, and you want to see more, please click here and follow the instructions.

�

Readers like you keep BritishRaceCar.com online and growing through voluntary financial contributions.

�

Features and Specifications

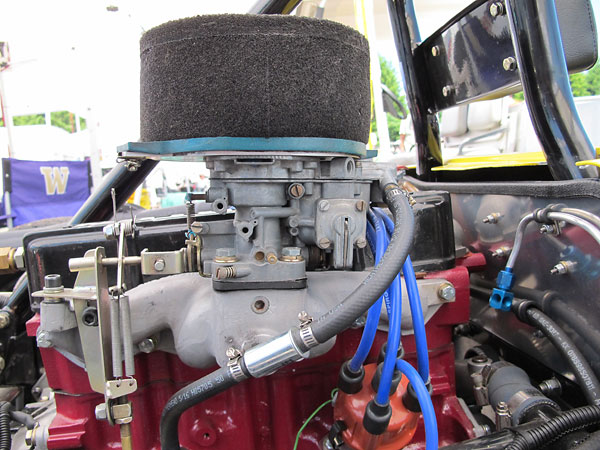

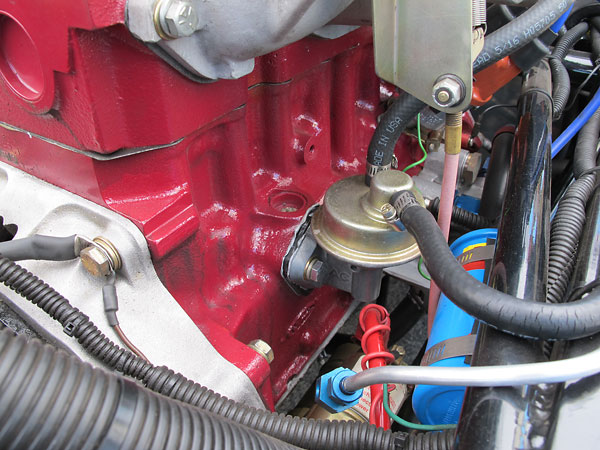

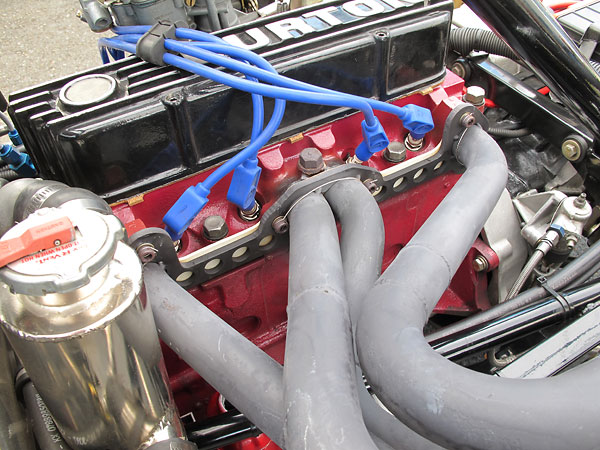

�| Engine: | �Ford Kent 1600cc with iron cylinder head, rebuilt by Ivey Engines, Inc.�

Burton aluminum valve cover.�

Weber 32/36 DGAV carburetor.�

BAT throttle linkage.�

RamFX foam air filter.�

Bosch distributor.�

Bosch blue ignition coil.�

Taylor Spiro-Pro 8mm silicone spark plug wires.�

Unlabeled oil pump.�

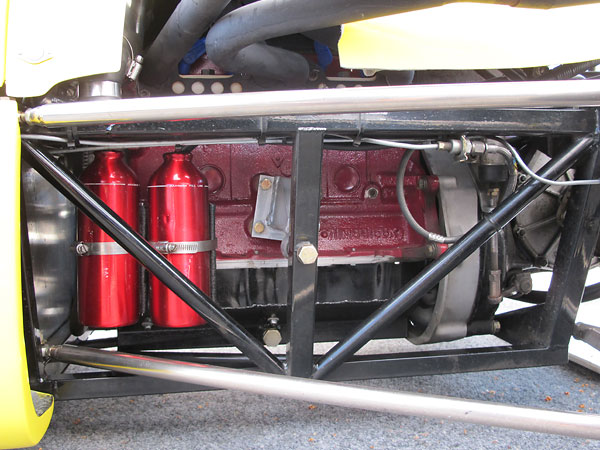

Dry sump lubrication system.�

Peterson engine oil reservoir. | �

| Cooling: | �copper/brass crossflow radiator.�

Custom fabricated coolant swirl tank.�

| �

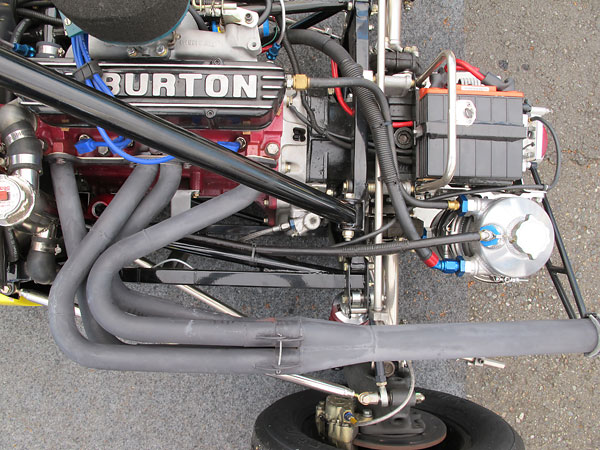

| Exhaust: | �custom four-into-one header from Ken Dye (DND). | �

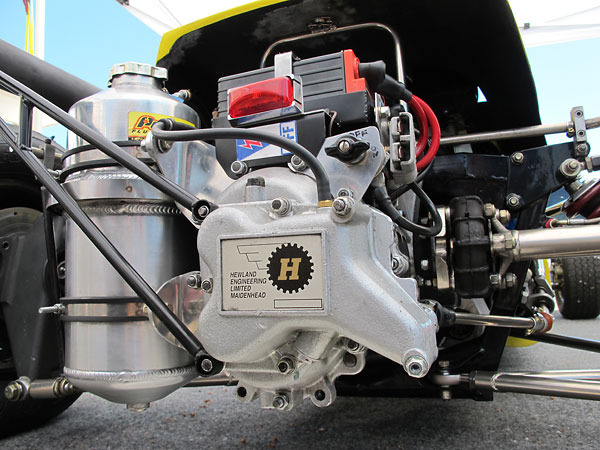

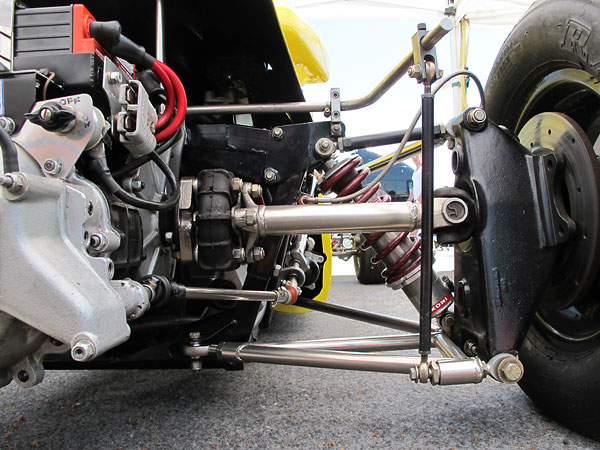

| Transaxle: | �Hewland Mk8/9 4-speed, with reverse, in a Mk6 case with Webster side covers.�

Metalastic drive donuts. | �

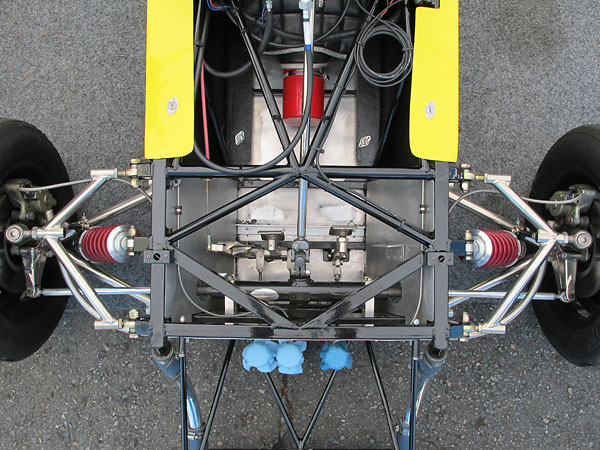

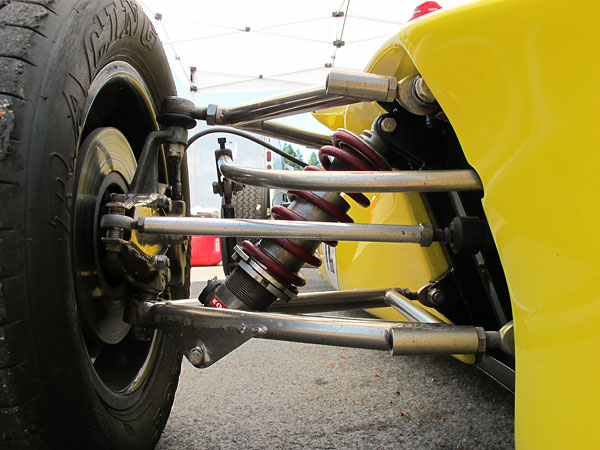

| Front Susp.: | �unequal length wishbones.�

Alford & Alder forged uprights, with custom fabricated steering arms.�

KONI double-adjustable, steel-bodied coilover shock absorbers.�

Eibach coil springs.�

Adjustable 5/8" anti-sway bar.�

March proprietary steering rack. | �

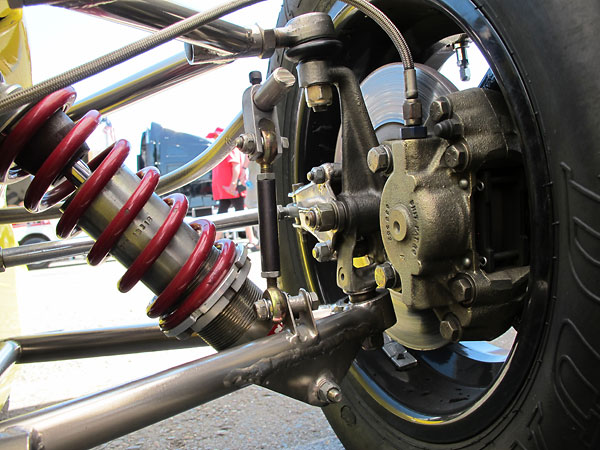

| Rear Susp.: | �inverted lower wishbones, single top links, and twin radius arms.�

Proprietary March magnesium uprights.�

KONI double-adjustable, steel-bodied coilover shock absorbers.�

Eibach coil springs.�

Adjustable 9/16" anti-sway bar. | �

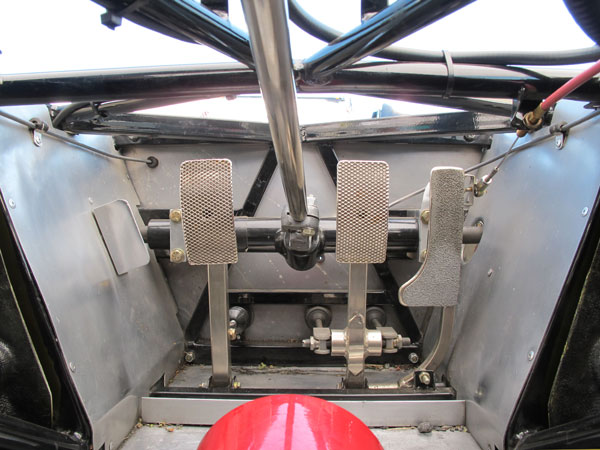

| Brakes: | �(master) dual Wilwood 5/8" master cylinders with integral reservoirs and adjustable bias bar. � (front) Girling 14LF calipers (casting# HDA21658). Triumph Spitfire solid rotors. � (rear) Girling 12SP calipers (casting# 64321547). Solid rotors (cross-drilled). | �

| Wheels/Tires: | �Revolution 4-spoke aluminum wheels (13x5.5).�

Dunlop Racing "Formula Ford" tires (135/545-13 CR82 front, 165/580-13 CR82 rear). | �

| Electrical: | �Odyssey battery (7.0kg)�

Lucas battery disconnect switch.�

Tilton Super Starter gear reduction starter.�

(No charging system.) | �

| Instruments: | �(left to right) Stewart Warner water temperature gauge (100-265F),�

Jones mechanical tachometer (1000-10000rpm),�

and Stewart Warner oil pressure gauge (0-100psi).�

| �

| Fuel System: | �Fuel Safe wedge-shaped, under-seat, aluminum fuel cell.�

AC mechanical fuel pump with push-on fittings. | �

| Safety Eqmt: | �OMP six point cam-lock safety harness.�

Mountney of Britain leather wrapped steering wheel, installed on a Troyer quick release steering wheel hub.�

Phoenix centralized fire suppression system. | �

| Racing Class: | �Formula Ford. | �

Engine Installation

��

�

Ford Kent 1600cc with iron cylinder head, rebuilt by Ivey Engines, Inc. - Jim reports: "Jay Ivey does

�

all of the engine work and is a real prince. If he's at the track, he always drops by to see how things

�

are running. If something doesn't sound just right, he rolls up his sleeves and fixes it on the spot."

�

�

This Burton aluminum valve cover is a period accessory. Jim says it seals better than a steel cover.

�

�

RamFX foam air filter atop a Weber 32/36 DGAV carburetor. BAT throttle linkage.

�

�

Bosch distributor with Taylor Spiro-Pro 8mm silicone spark plug wires.

�

�

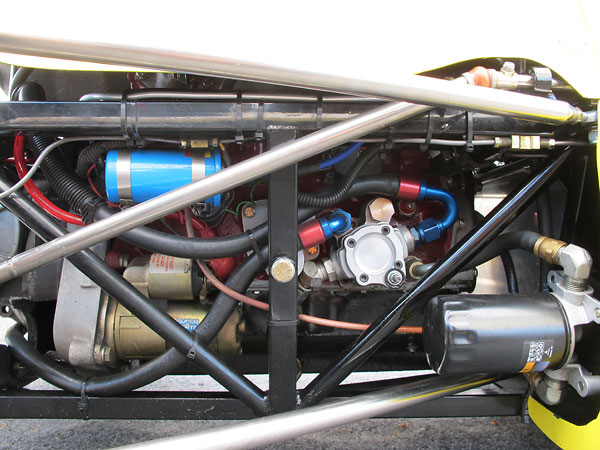

At left, Tilton Super Starter gear reduction starter. At right, Mitchell Engineering's very distinctive oil

�

filter mounting base. These bases were originally made for another of Wayne's businesses. Wayne

�

made and sold "Vari-Cam" kits for hot-rodders to update their American V8s with mechanically

�

variable camshaft timing. He still has inventory of old oil filter mounting bases if you need one.

�

�

AC mechanical fuel pump with push-on fittings. At right: Bosch blue ignition coil.

�

�

Ken Dye custom made this authentic looking copy of the original four into one exhaust header.

�

Wayne explained that only one example header was provided to him by March. He turned

�

it over to a fabrication shop in California and paid them to make duplicates for production.

�

�

The header tubes were tack welded to the header flange at intervals on this side, and then welded

�

all the way around their circumferences on the cylinder head side.

�

�

Casting number 711M6015BA indicates that this block is a 1600cc "tall" block with big bearing caps.

�

(Note: these motor mounts aren't the original style.)

�

�

This is either an original Mitchell Engineering fabricated coolant swirl tank or an excellent replica.

�

The original swirl tanks were mild steel, brazed with nickel-bronze filler rod. How do they work?

�

the swirling of coolant helps entrapped steam bubbles escape to head space at the top.

�

�

Graham Coaker was a Serck rep, so March always used Serck radiators on their UK produced cars.

�

�

After the first few USA built cars, Mitchell Engineering sourced radiators from a local (California) shop.

�

In either case the radiators were similar in design, construction, and materials. The only easy way

�

to tell them apart would be to look for a Serck badge.

�

�

Hose connections between water pump and frame.

�

�

A new Peterson Fluid Systems engine oil reservoir is mounted by the transaxle, whereas March originally

�

put their oil tanks under the driver's seat. No engine oil cooler is installed! March never put one on, nor

�

recommended one. Jim has run this car eleven years without overheating and without any oil related

�

failures. He uses a special blend synthetic oil developed by Jay Ivey and a NAPA Gold oil filter.

�

�

A thick steel adapter is installed so rubber donuts can be used in lieu of CV joints with these particular

�

transaxle output shafts. Class rules mandate rubber donuts, but appropriate drive flanges for installing

�

them are getting hard to find for Hewland Mk8 and Mk9 transaxles, so people use various adapters.

�

Not quite visible in this view, Jim explained one more important construction/preparation detail: "'I've

�

installed a set of Wayne's Donut Savers. They should really be called 'back end of your car savers'.

�

They work! I had a donut bolt failure and the joint stayed intact. I found the broken bolt after a

�

competitor mentioned that my halfshaft had a wobble on the cool down lap."

�

�

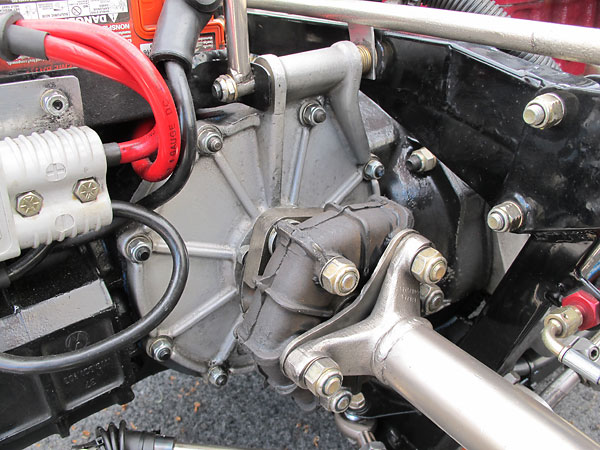

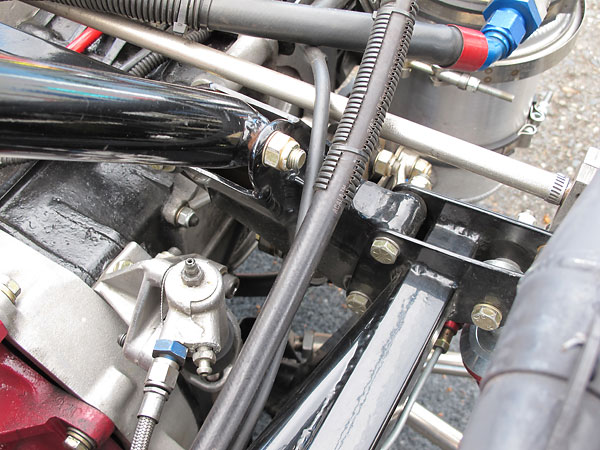

Notice that someone has added an extra bleed nipple to the end of this Girling clutch slave cylinder.

�

It's important to get all the air out of the system so the driver will sense a nice, firm pedal feel.

�

�

Odyssey battery (7.0kg), HMS jump start plug, and Lucas battery disconnect switch.

�

�

Front Suspension

��

�

Koni steel-bodied double-adjustable shock absorber. March originally fitted Armstrong single-adjustable

�

shocks. On these Koni shocks, rebound dampening is adjusted at the narrow horizontal slot seen at the

�

top while compression is adjusted by a knob on the shocks' bodies. On Armstrongs, valves on the main

�

body are turned with a blade screwdriver to alter both rebound and compression characteristics at once.

�

(Mitchell Engineering still rebuilds Armstrong shock absorbers. Very few other shops do.)

�

�

An interesting feature of the March design: the steering rack is located rearward of the front bulkhead.

�

�

The steering rack lines up with uncommonly short steering arms. The March design called for specially

�

fabricated steering arms instead of the off-the-shelf parts most other Formula Ford constructors used.

�

Certainly all the 719 and 729 cars had them. Result: quicker steering.

�

�

March's custom fabricated steering arms put the Heim joints in double shear (a very good thing) and

�

also made attachment height more readily adjustable so bump steer could easily be tuned out.

�

�

Wayne Mitchell made a variety of anti-sway bars for the March Formula Fords, all fabricated in house, and

�

all featuring big sweeping curves instead of small radius bends. (This bar appears to be "original".)

�

�

Girling 14LF calipers (casting# HDA21658). Solid rotors.

�

�

These are steel-bodied shock absorbers. An otherwise identical but lighter weight aluminum-bodied

�

version is available, but is explicitly prohibited for the vintage Formula Ford racing by most clubs.

�

(In Jim's club, the aluminum bodied version would be allowed for the Formula B class.)

�

�

A portion of shock absorber mass moves up and down with the wheel. In other words: it's unsprung weight.

�

Racers put special value on reducing unsprung mass because it disproportionately affects tire grip (as well as

�

ride quality.) Generally, aluminum shocks also dissipate heat better, for more consistent performance.

�

�

Wilwood replacement brake master cylinder. (This one is marked "5/8", which is its bore diameter.)

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

Rear Suspension

��

�

Note that March had their own distinctive magnesium uprights.

�

�

What made Mitchell Engineering built March Formula Fords different from the earlier UK-built version?

�

One difference was plumbing: Mitchell Engineering installed Aeroquip stainless steel braid reinforced

�

hoses in lieu of simple rubber hoses.

�

�

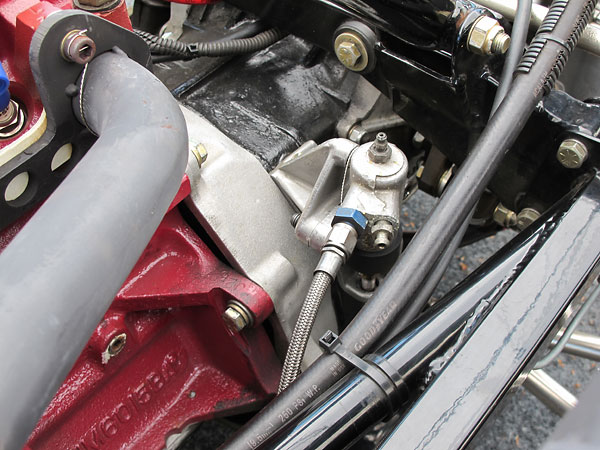

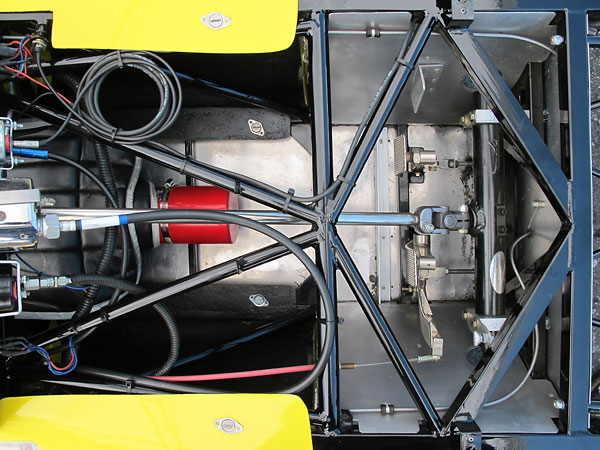

The shifter linkage is routed high as it passes the engine bulkhead to provide clearance to the original

�

fuel cell placement. March's F3 cars had dual fuel cells, one under each of the drivers elbows. March

�

Formula Fords were built with similar cells, placed on either the left or right side. (Production varied.)

�

�

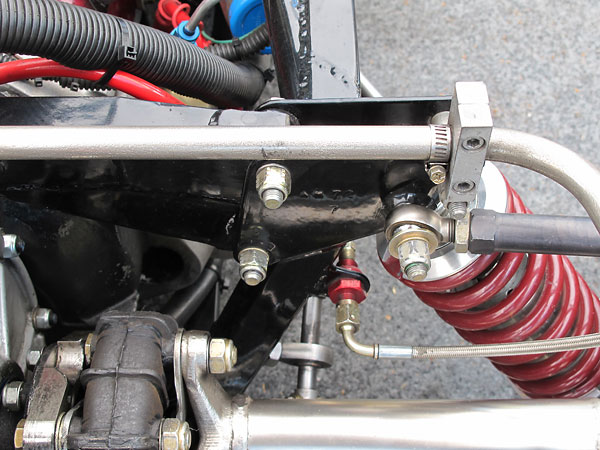

Wayne equipped 719 and 729 Formula Fords with a distinctive clamp of his own invention which made

�

their shifter linkages infinitely adjustable in both length and rotation. It's a split-block design, and in

�

this view it can be seen just beyond the Heim joint which is in turn just beyond an Apex u-joint.

�

Wayne still offers these clamps, and they've been retrofitted to many other Formula Fords.

�

�

The frame appears to be stamped "AM 72 7" - but don't be fooled. This isn't an Arch Motors constructed

�

frame. All fourteen 719 and 729 Marchs had frames fabricated by Wayne Mitchell in California. Wayne

�

stamped his own initials and the date of manufacture into the rear lefthand (not righthand, as shown here)

�

corner of the frame. Most 729 frames were actually assembled in 1971, and were therefore stamped "71".

�

�

Rear crossmember and roll hoop brace connections.

�

�

Lower trailing link connection to the frame.

�

�

Interior

��

�

A comfortable and attractive custom drivers seat.

�

�

OMP six point cam-lock safety harness.

�

�

Mountney of Britain leather wrapped steering wheel.

�

�

Troyer quick release steering wheel hub. The label says: "Innovation, not duplication."

�

�

Stewart Warner water temperature and oil pressure gauges, and Jones mechanical tachometer.

�

Back in the day, March supplied Mitchell Engineering with Smiths tachometers. However, Mitchell

�

bought Stewart Warner coolant temperature and oil pressure gauges locally. When restoring the

�

car, Jim contacted Wayne Mitchell to see if he might borrow an original dashboard template, and

�

instead Wayne mailed him a spare, original aluminum dashboard.

�

�

Close-up view of the gear selector mechanism.

�

�

Floor mounted pedals. March used similar pedals for Formula 3. Note also the heel bar and dead pedal.

�

�

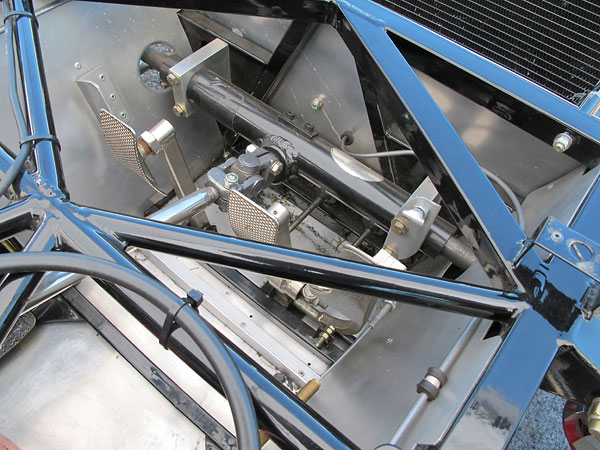

Mitchell Engineering racks are very distinctive. Whereas UK-built (Jack Knight et al) steering racks

�

typically featured cast magnesium or aluminum housings, Mitchell Engineering fabricated racks

�

from heavy wall aluminum tubing, heliarc welded and then finally either silver or black anodized.

�

(Mitchell Engineering still offers custom made racks constructed by this method.)

�

�

March's Formula Ford frames were stiff, if a little on the heavy side. They were constructed from

�

a pragmatic mix of round and box section steel tubing. (Note the coolant sensor bung at upper left.)

�

�

Updated details: roll hoop construction, shoulder harness attachment, and plumbing for under-seat fuel cell.

�

March provided each Formula Ford with one foam-filled rubber fuel bladder mounted under a side-pod

�

(usually on the right side), protected only by fiberglass bodywork. An engine oil reservoir was mounted

�

behind the drivers back. One consequence of this approach was additional heat in an already warm

�

cockpit so Jim decided to install a new Peterson oil tank out back by the transaxle. This freed-up

�

room for installing a new wedge-shaped Fuel Safe fuel cell behind the drivers seat.

�

�

Exterior

��

�

Jim Johnson acquired this rare March Formula Ford as a basket case. Between 1971 and '72,

�

fourteen of these cars were made for March by Wayne Mitchell (d.b.a. Mitchell Engineering)

�

in Southern California. The design and many of the parts were provided by March's workshop

�

in England. Mitchell produced frames, bodies, and many other fabricated and machined parts.

�

When March sold Formula Fords to American customers, Mitchell drop-shipped the cars.

�

�

The car's body was missing when Jim got it, so he borrowed bodywork from another March 729 owner.

�

From the five borrowed body parts, Frank Martinez made new molds and replacement body panels.

�

Frank Martinez also made a spare body panel set for Wayne Mitchell.

�

�

Mitchell Engineering didn't provide engine covers on the March Formula Fords they produced, but

�

this car had one when Jim bought it. The original source of his cover is unknown, but because of the

�

engine cover Jim believes his car is probably the same March 729 shown in Steve Nickless' book,

�

"The Anatomy and Development of the Formula Ford Race Car". (March's early UK-produced cars

�

came with engine covers, but they were shaped differently.)

�

�

Jim and his daughter are big fans of Douglas Adams, including his "Hitchhikers' Guide to the Galaxy".

�

When they needed to select a racing number, "42" seemed the right choice.

�

�

SOVREN (Society of Vintage Racing Enthusiasts in the Northwest) Vintage Racing

�

Jim wrote: "Al Murray, a fellow SOVREN open wheel racer and past club President was a great

�

mentor. He talked me through the restoration process when I first got the car 12 years ago."

�

�

55 - Russ Bishop - 1939-2009

�

(Russ raced a Formula Ford in SOVREN events over several years.)

�

�

Revolution 4-spoke aluminum wheels (13x5.5). By 1972, aluminum or magnesium wheels would

�

have been allowed on Formula Fords anywhere they raced in the United States. (Not so in the rest

�

of the world!) Nonetheless, all March Formula Fords were sold with steel wheels. The performance

�

difference is large, so any serious racer would certainly have upgraded. SOVREN generally follows

�

"Monoposto" rules, but they've made a specific exception to allow aluminum wheels.

�

�

Dunlop Racing "Formula Ford" tires (135/545-13 CR82 front, 165/580-13 CR82 rear).

�

| Notes: | |||||||

| (1) | �

Per racecar historian Chris Townsend, March's 1971 Formula Ford production was as follows:�

� 718-1: a rebuild of chassis 708-6 for employee Bill Stone's personal use. � 718-2: a rebuild of chassis 708-5 for Colin Andrews, UK. � 718-3: for Chris Tipping, UK. By 1976 this car was being raced in UK by Willie Moore. � 718-4: for Andrew Chatburn, UK. � 719-1: for Gordon Dewar, CA. � 719-2 (frame AM71-5): for Ric Forest, CA. � 719-3 (frame AM71-11): Tom Johnston, CA.� � Per Wayne Lee who currently owns 719-2, March updated the design of the cigar noses on� UK-produced 719s from previous models by adding a NACA-style duct forward of� the instrument panel.� | ||||||

�

Unless otherwise noted, all photos shown here are from June 2011 when we viewed this car�

at The Pacific Northwest Historics at Pacific Raceways in Kent, Washington.�

All photos by Curtis Jacobson for BritishRaceCar.com, copyright 2011.�

All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Howard Freeman 1968 Merlyn 11 | �

| �

Scott Fairchild 1972 Royale RP3A | �

| �

Gord Leach 1974 Hawke DL11 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�