�

�

Gord Leach's 1974 Hawke DL11 Formula Ford Racecar

� � Owner: Gord Leach� City: Regina, Saskatchewan

� Model: 1974 Hawke DL11

� Engine: 1.6L Ford four-cylinder

� Race prepared by: owner�

�

David Lazenby and his Hawke Racing Cars

��

David Lazenby joined Lotus in 1961, and in 1963 he was assigned to be Jim Clark's race mechanic.�

In this capacity he prepared and maintained Clark's Formula One and Indianapolis 500 cars.�

Lazenby was a central figure in the small team that helped Clark win the 1965 Indy 500. His�

career at Lotus looked bright. In 1968, Lazenby was named General Manager of Lotus Components Ltd.,�

the division of Lotus which built racecars for outside customers. These were the early days of�

the exciting new Formula Ford amateur racing class, and customer demand for Lotus 51 Formula Fords�

was booming.�

�

Apparently the promotion didn't suit Lazenby well enough, because at the end of the 1968�

he resigned from Lotus and started his own racecar business. David Lazenby & Co. Ltd.�

only sold a modest number of Formula Fords and never advanced into building cars for�

professional racing classes, but ultimately Lazenby's company produced some very successful�

Formula Ford racecars. David Lazenby was the principle designer of all their models.�

�

From early 1969, Lazenby worked out of a small workshop in the cozy parish village of Nazeing�

(near Waltham Abbey). Lazenby shared the shop with an old hawk, and soon appropriated and modified�

the word "hawk" as a trade name for his products. The very first Hawke racecar was built to order�

for the man who owned the workshop building. Retrospectively identified as a DL1, this car is�

remembered as the prototype for the DL2, DL2A and DL2B models which followed.�

The DL1 featured an unusually long nose cone which proved vulnerable in traffic, and also an�

uncommonly well-braced frame because driver protection was a design priority from the company's�

beginning. From the early days of his new enterprise, Lazenby kept bills paid by producing�

close-ratio gears for the Renault gearboxes used in early Lotus Formula Fords. (Hewland gears�

and steering racks became staple products later.) After a short while, Lazenby relocated to a�

larger premises on the Waltham Cross high street.�

�

Canada and the United States proved especially receptive markets for Hawke cars and sales grew.�

According to a contemporary Motor Sport magazine article ("They Make Racing Cars", December 1971)�

28 Hawke DL2 Formula Fords were built in 1969 followed by 54 Hawke DL2A cars in 1970. (The Hawke�

Registry reports a much lower number.) A Hawke DL2A won the 1970 Canadian "Bulova Cup"�

Formula Ford Championship. Aside from a handful of examples that prove the rule, DL2 and DL2A�

frames were fabricated to order from Racing Frames and from Arch Motors respectively.�

�

�

�

David Lazenby & Co. Ltd.

�

Model DL11, Chassis No. 016, Engine No. (blank), Gearbox No. (blank)

�

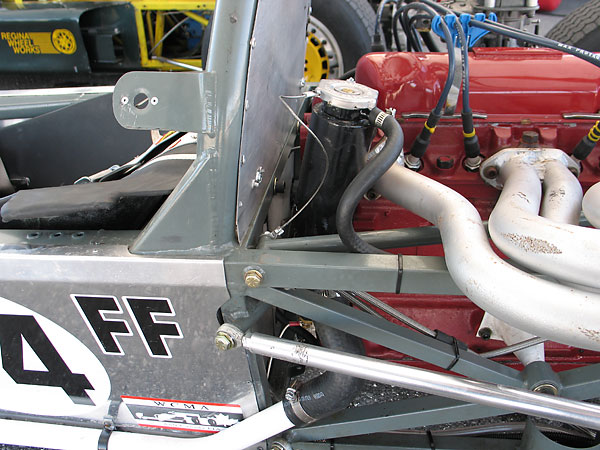

(Note also the custom fabricated adjustable steering column support.)

�

�

For 1971, production was split between the latest revision of the Formula Ford model (DL2B)�

and a new Super Vee model (DL5). By late 1971, Hawke frame production moved in-house. Interestingly,�

Hawkes always used fabricated steel uprights (a.k.a. hub carriers) rather than any sort of cast or�

forged uprights. They reasoned and advertised that these were safer because they would likely�

deform but not fracture in most severe accidents. Hawke kept most of their small fabricated parts�

in-house. Several different suppliers were tried for fiberglass body panels. At least through the�

early years, SAH Accessories in Leighton Buzzard was their preferred fiberglass supplier.�

�

For 1972, production was split between two new models the Hawke DL8 for Super Vee and the Hawke DL9 for�

Formula Ford. According to the company's sales literature, the two models had exactly the same�

nominal wheelbase (88.5"), track (54.0" front and rear), and weight (882 pounds). What's really�

interesting about these two models is the design of their space frames; instead of round tubes, these�

new models and their successors were mainly constructed from box tubing and special "formed beams�

in the cockpit to provide great strength and maximum driver protection." Whereas earlier Hawke�

Formula Fords had nose pod mounted radiators, the DL9 had two side mounted Serck radiators supplemented�

by a nose mounted oil cooler. About 30 Hawke DL9 race cars were produced.�

�

For 1973, Super Vee had largely fizzled out and the company's production focused on a new�

Formula Ford model, the Hawke DL10. Both the space frame and the body were substantially different�

from the previous (DL9) model, but performance was disappointing. About 25 Hawke DL10 race cars were�

produced, but many of them were upgraded to DL11 specifications. (Changes included updated rear�

suspension pick-up points and geometry.)�

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

With the Hawke DL11 David Lazenby finally had a top performing Formula Ford design. The difference�

came through extensive testing. An enthusiastic employee named John Bicht got on track and drove the�

DL11 test mule at every reasonable opportunity over the course of its seven month development. Another�

driver's name is also closely associated with the DL11: Syd Fox drove a DL11 to victory in the�

1973 Sunbeam Electric Championship, and also to an impressive third place finish in the 1973 Formula�

Ford Festival. (Formula Ford was a popular enough class in England through this era that three competing�

championship series were held. The Formula Ford Festival ended up more prestigious than any of these�

because it brought together top drivers from all over England and also from much of Europe.)�

�

Although Formula Ford was still popular, sales were down for most race car constructors through�

1973 and 1974. Following the Arab oil embargo, gasoline was a precious commodity and there were�

persistent pernicious rumors that racing might be banned. Only about 30 Hawke DL11 race cars were�

built, although production spanned from 1973 through 1974. Late in 1974, Lazenby produced a very�

small number of specially streamlined "Super Slipstreamer" (a.k.a. DL12) Formula Fords. Roy Klomfass�

drove a Super Slipstreamer to Sunbeam Electric Championship victory in 1974. �

�

Even greater success awaited future Hawke models. Lazenby's cars dominated the 1976 Formula Ford�

Festival with Derek Daly, Derek Warwick, and Rick Morris in a 1-2-3 finish (driving two DL17s and�

one DL15, respectively.) A young driver named Nigel Mansell also drove a Hawke DL17 throughout his�

1976 season.�

�

Besides Gord Leach's car, the Hawke Registry lists ten remaining Hawke DL11 racecars (worldwide),�

plus three DL12s. No Hawke DL10 racecars are known to have survived.�

�

�

�

�

�

�

Discovered: Factory-Recommended Hawke DL11 Set-Up Measurements

�| Front | Rear | ||

| Ride height | 2.75"-3" | 3.5"-3.75" | |

| Camber | 0.5 degree | 1 degree | |

| Castor | 0.75 degree | 0 degree | |

| Toe-in | 1/16" each wheel | 1/16" each wheel | |

| Dampers | 1 turn | 1.75 turn | |

| Tire pressure | 14-16 psi | 16-18 psi |

Features and Specifications

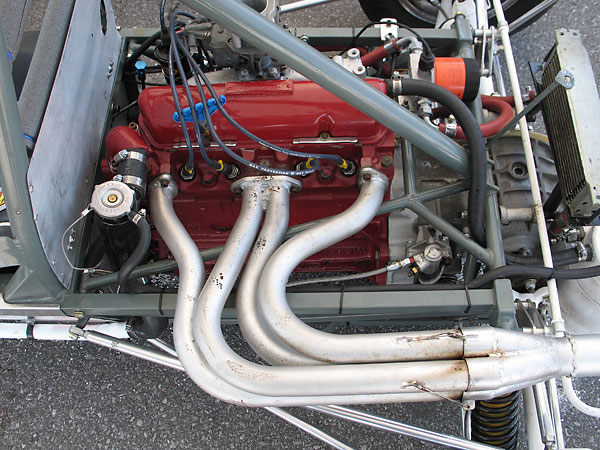

�| Engine: | �1.6L Ford four-cylinder, built by Brian Stewart Racing Inc., Toronto Canada.�

Weber 32/36 DGV carburetor.�

Shankle tuned length velocity stacks (used without filters).�

Motorcraft distributor.�

Belden Premium 7mm spark plug wires.�

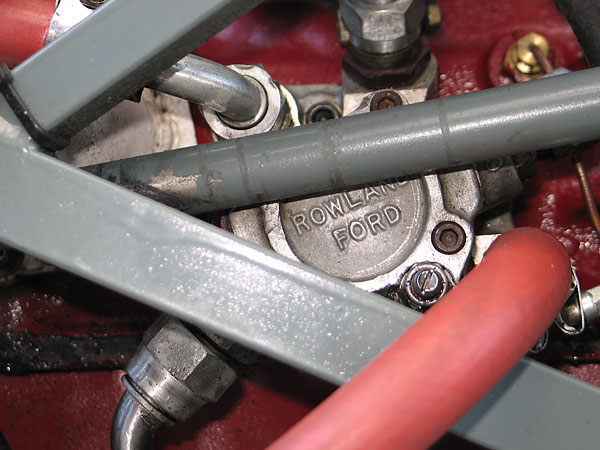

Rowland Ford oil pump.�

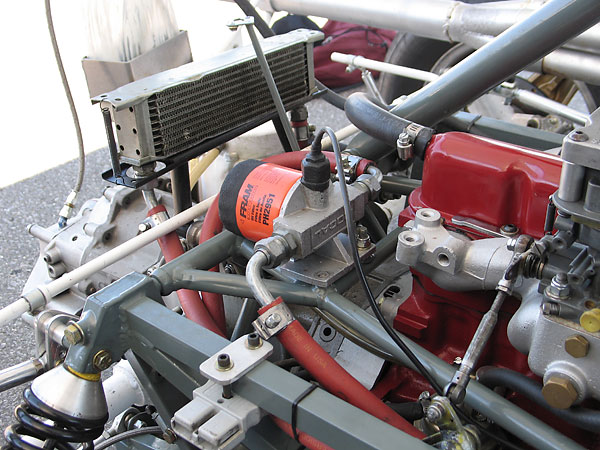

Mocal remote oil filter mount.�

Fram PH2950 oil filter.�

Mocal 10-row oil cooler. | �

| Cooling: | �original copper/brass crossflow radiator. | �

| Exhaust: | �four-into-one header. | �

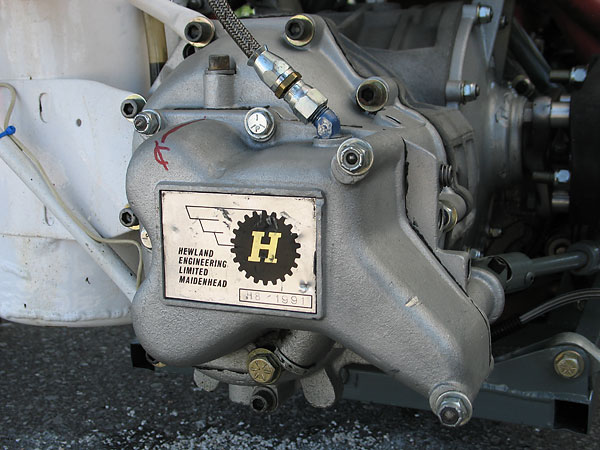

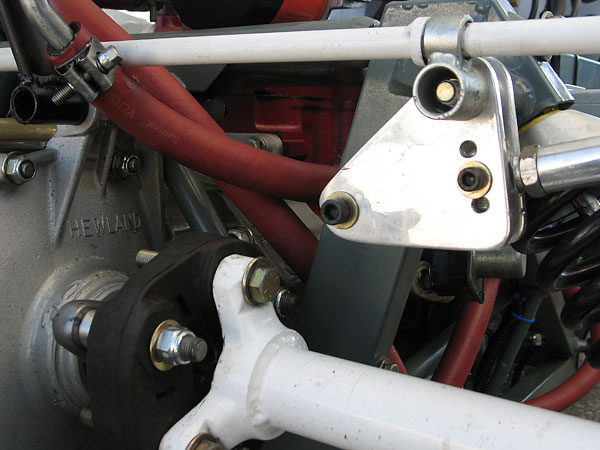

| Transmission: | �Hewland Mark 8 4-speed. | �

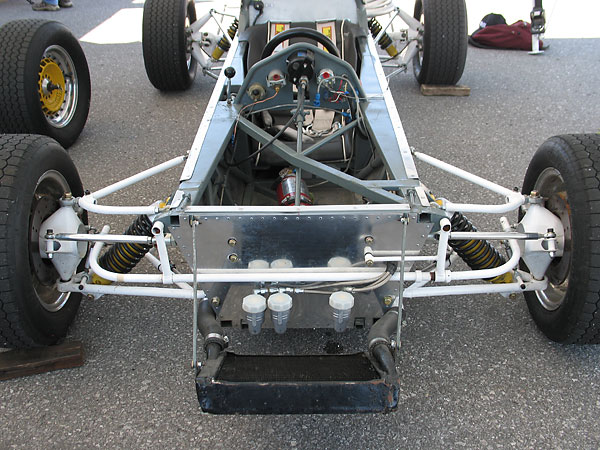

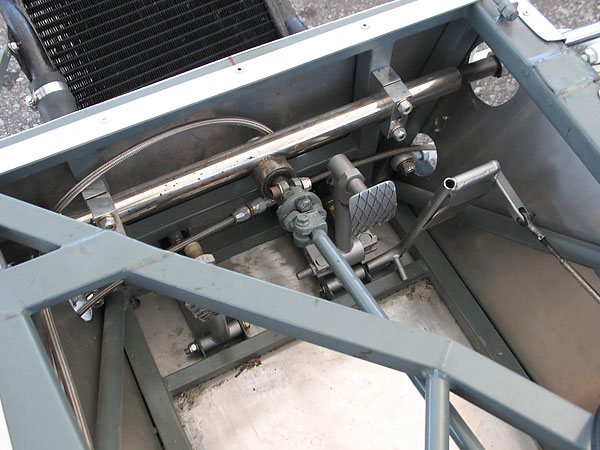

| Front Susp.: | �unequal length wide-based wishbones.�

Hawke proprietary fabricated steel uprights.�

Spax steel bodied adjustable coilover shock absorbers.�

Adjustable tubular 5/8" anti-sway bar. | �

| Rear Susp.: | �dual lower links, single top links, and twin adjustable trailing links.�

Hawke proprietary fabricated steel uprights.�

Spax steel bodied adjustable coilover shock absorbers.�

Adjustable tubular 1/2" anti-sway bar. | �

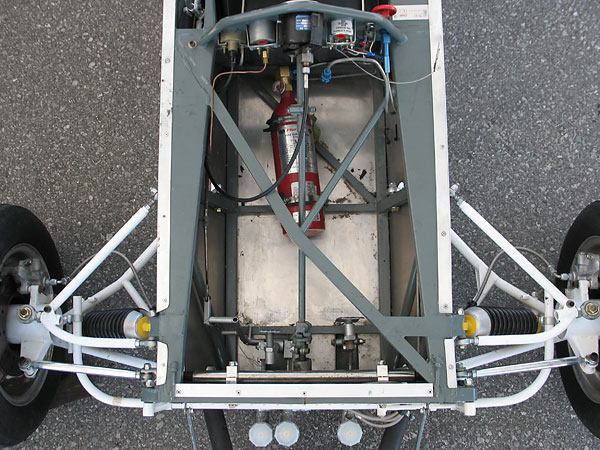

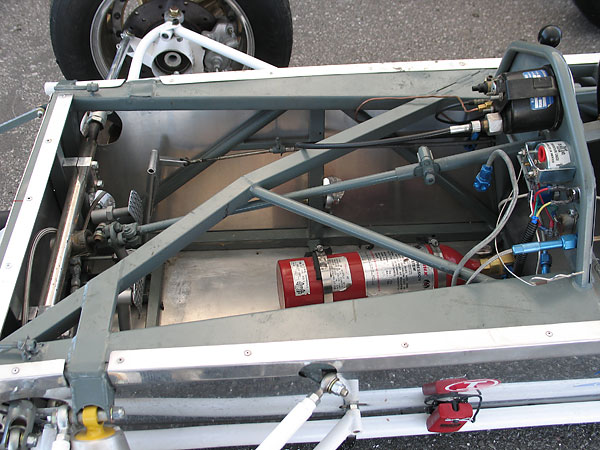

| Brakes: | �(master) dual Girling master cylinders with integral reservoirs, and with bias bar. � (front) Lockheed LD20 calipers. Cross-drilled rotors. � (rear) Lockheed LD20 calipers. Cross-drilled rotors. | �

| Wheels/Tires: | �Revolution modular (3-piece) aluminum wheels.�

Dunlop Racing "Formula Ford" tires (135/545-13 CR82 front, 165/580-13 CR82 rear). | �

| Electrical: | �Lucas master battery cutoff switch.�

PowerSonic PS12180 sealed absorbent glass mat lead/acid battery. | �

| Instruments: | �(left to right) Stewart Warner water temperature gauge (100-230F),�

Jones mechanical tachometer (0-10000rpm),�

Stewart Warner oil pressure gauge (5-100psi). �

Stewart Warner oil temperature gauge (140-325F).�

| �

| Fuel System: | �ATL FC152 5-gallon fuel cell.�

FF1600 mechanical fuel pump with push-on fittings. | �

| Safety Eqmt: | �Racers Choice six-point cam-lock safety harness.�

Phoenix centralized fire suppression system.�

Quick release steering wheel hub, on a Moto-Lita steering wheel. | �

| Racing Class: | �Formula Ford. | �

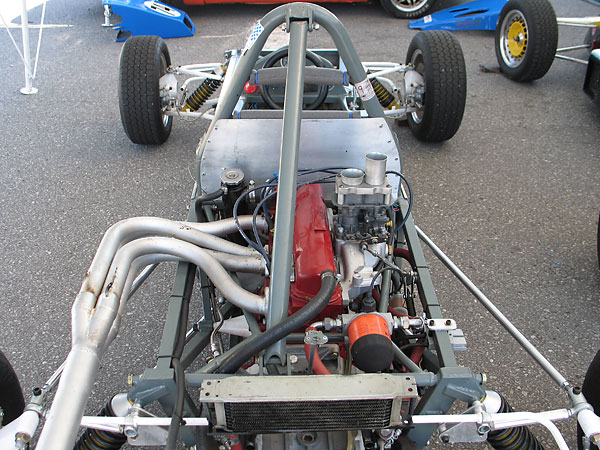

Engine Installation

��

�

Brian Stewart Racing Inc. of Toronto once built this engine. Mechanic, turned Formula Ford championship winning

�

driver, turned professional racing team owner... Brian Stewart is among the best known and most respected figures

�

in Canadian racing. His team won the Indy Lights championship in 2005. BSR is also a full service race shop.

�

�

Weber 32/36 DGV carburetor on an original Ford intake manifold, as mandated by class rules.

�

�

Shankle velocity stacks are designed to make altering induction tract length easy. The effect is somewhat like

�

optimizing exhaust lengths. Trimming the trumpets generally shifts peak torque to a higher engine speed.

�

Fitting longer trumpets has the opposite effect. In either case, the bell of the trumpet helps smooth airflow

�

into the induction tract. (The bigger the bell radius, the better.) Here, one stack is shorter than the other.

�

This may have been done to correct mismatched intake manifold runner lengths.

�

�

Full size starter motor.

�

�

Rowland Ford oil pump.

�

�

Mocal remote oil filter mount and Fram PH2950 oil filter. Mocal 10-row oil cooler.

�

�

4-into-1 exhaust header. Girling clutch slave cylinder.

�

�

The filler cap is up high to ensure that coolant fills the cylinder head's water jacket.

�

�

Casting number 711M6015BA indicates that this block is a 1600cc "tall" block with big bearing caps.

�

�

Hewland transaxle: H8-1991

�

�

Metalastic drive donuts are a characteristic component of vintage Formula Fords.

�

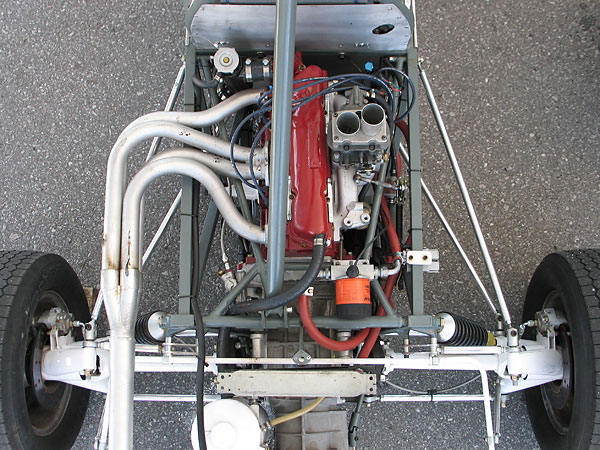

Front Suspension, etc.

��

�

One unusual feature of all Hawke suspensions is their fabricated steel front and rear uprights (a.k.a. hub

�

carriers). Their competitors mainly used Alford and Alder forged front uprights (from Triumph street cars)

�

or custom magnesium castings. Hawke promoted their steel uprights as a safety over magnesium or

�

aluminum castings because they're more likely to bend rather than break in an accident.

�

�

Whereas many early Formula Ford constructors routed coolant to front-mounted radiators through

�

frame tubes, Hawke preferred to mount coolant lines outboard of the frame. Note also that this

�

original copper-and-brass radiator is flexibly supported by just two stay rods and two hoses.

�

�

This frame is primarily composed of square "box" tubing, where other early Formula Ford designs

�

mainly used round tubing. Among the advantages of box tubing: frame joints are easier to fabricate

�

since no "fishmouth" cuts are required and the flat surfaces of the tubes make it easier to install

�

bulkheads or to mount accessories. Generally, round-tube frames can be made lighter weight.

�

�

Mounted atop the corner of the frame, you can see one of the pins that locate the bodywork.

�

�

Old Hawke sales literature indicates that either Armstrong or Spax shock absorbers were provided.

�

�

Evidentally to correct a bump steer issue, steering links have been reconnected to the uprights above

�

their normal connection point. (In the "before picture", steering links were connected this way too.)

�

In this view, you can also see the shock absorber adjustment valve.

�

�

Vintage Formula Ford racecars use steel-bodied shock absorbers. (Club rules prohibit aluminum shocks.)

�

In this view you can also see that the car has Lockheed LD20 calipers, which would have been a very

�

modern spec for 1973. Up until that time, Girling calipers were ubiquitous in Formula Ford.

�

�

Note the clamp on the steering column which facilitates moving the steering wheel rearward.

�

This view also shows the wide spacing of rivets on the car's aluminum side panels. Class rules

�

explicitly prohibited closer rivet spacing to keep side panels from functioning as "stressed skins".

�

(It was a stupid rule for many reasons. For example, adhesives were already available which were

�

stronger than rivets and completely undetectable without dissassembly. Besides, why shouldn't a

�

race car chassis be as strong and as safe as possible, especially when the difference is so cheap?)

�

�

Unlike many other early Formula Fords, on the Hawke DL11 the steering rack is mounted rearward of the

�

frame's front bulkhead. Hawke constucted their own steering racks, and in fact offered custom made

�

steering racks for all sorts of applications. Note also the flexible steering shaft coupling (a.k.a. rag joint).

�

�

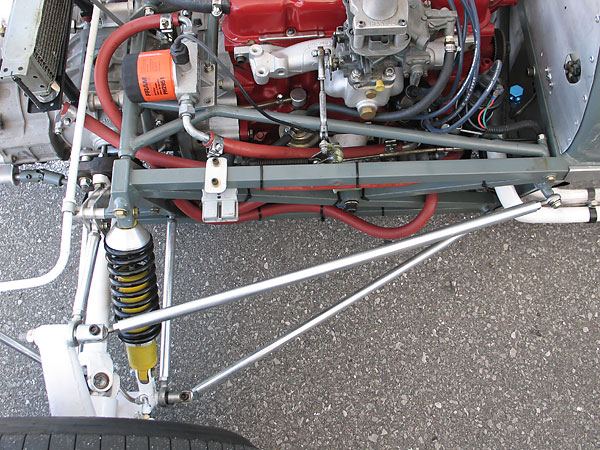

Rear Suspension

��

�

Dual lower links, single top links, and twin adjustable trailing links.

�

�

A robust roll hoop brace.

�

�

When Gord purchased his DL11, it had a canister muffler clamped just behind the exhaust collector.

�

�

One way to make radius rods is to drill and tap holes into the ends of solid extruded aluminum bars.

�

The original radius rods were made from steel tube with welded-on threaded plugs at each end.

�

�

The core of a solid anti-sway bar adds very little to its torsional stiffness, so it makes

�

excellent sense to use tubing instead - as shown on both the front and rear of this racecar.

�

�

Although painted now, the engine oil reservoir is an aluminum fabrication.

�

�

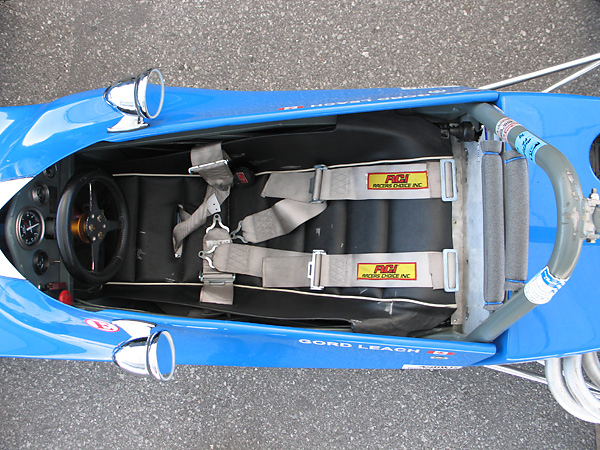

Interior

��

�

Moto-Lita steering wheel.

�

�

Quick release steering wheel hub.

�

�

Stewart Warner water temperature gauge (100-230F), Jones mechanical tachometer (0-10000rpm),

�

Stewart Warner oil pressure gauge (5-100psi) and oil temperature gauge (140-325F).

�

�

Fabricated steel instrument panel.

�

�

Racers Choice six-point cam-lock safety harness.

�

�

Gear selector.

�

�

Phoenix centralized fire suppression system.

�

�

Lucas master battery cutoff switch.

�

�

PowerSonic PS12180 sealed absorbent glass mat lead/acid battery.

�

�

ATL FC152 5-gallon fuel cell.

�

�

Exterior

��

�

During VARAC's 31st Intl. Vintage Racing Festival at Mosport, Gord Leach piloted his vintage Hawke DL11

�

Formula Ford around the challenging 3.957Km racetrack with lap speeds of about 1 minute, 49 seconds.

�

That works out to an average speed of over 130.2kph (~80.9mph).

�

�

decal: United States 40th Anniversary of Formula Ford, Road America, July 24-26, 2009.

�

�

It sits high empty, but it will settle with nicely with the driver installed.

�

Factory reccommended ride height: 2.75"-3" (front) and 3.5"-3.75" (rear).

�

�

decal: BlurredVisionRacing.com

�

�

After a couple years of experience with side-pod mounted radiators, Lazenby returned to a single

�

nose-pod mounted radiator for the Hawke DL11. Coolant was routed in external lines by necessity.

�

�

decal: Race Sport Performance of St. Andrews, Manitoba

�

�

Revolution modular (3-piece) aluminum wheels.

�

�

Dunlop Racing "Formula Ford" tires (135/545-13 CR82 front, 165/580-13 CR82 rear).

�

�

All photos shown here are from June 2010 when we viewed the car at VARAC's 31st Intl. Vintage Racing Festival�

at Mosport Motorsports Park, in Ontario Canada. Photos by Curtis Jacobson for BritishRaceCar.com, �

copyright 2010. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Dick Leehr 1968 Lotus 51c | �

| �

Scott Fairchild 1972 Royale RP3A | �

| �

Michael Snowdon 1972 GRD 272 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�