�

�

John McCue's 1972 MG Midget, Number 66

� � Owner: John McCue� City: Charleston, West Virginia

� Model: 1972 MG Midget

� Engine: 1275cc BMC A-series

� Built by: owner�

�

Features and Specifications

�| Engine: | �1275cc Spridget engine with 0.040" overbore. �

JE forged pistons. �

Carrillo connecting rods.�

Stock crankshaft, reworked by Moldex Crankshaft Co. �

Steel main caps with ARP hardware. �

Ported and polished cylinder head (1.4" intake valves and 1.14" exhaust valves.)�

14.2:1 static compression ratio. �

Huffaker Engineering camshaft and valve springs. �

Titanium retainers and bronze valve guides. �

ARP valvetrain hardware. �

APT lifters, with radius recut. �

Titan roller rockers (1.5:1 ratio.)�

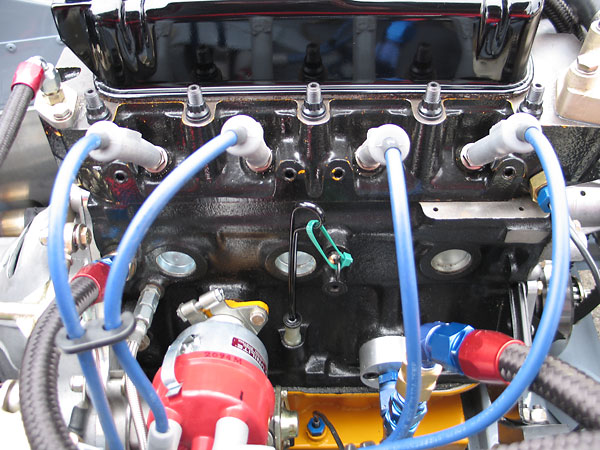

Mallory Unilite distributor. �

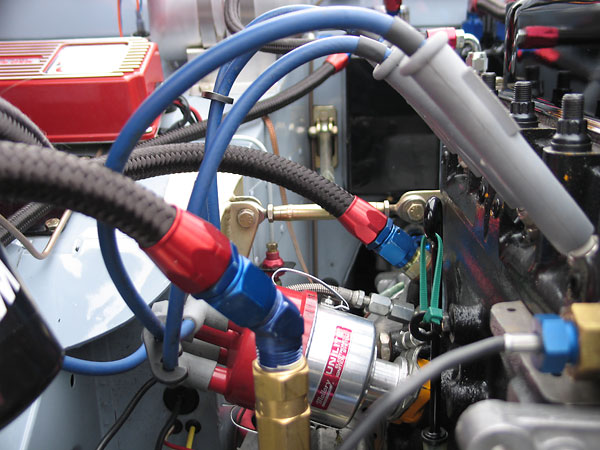

MSD6AL capacitive discharge ignition system. �

MSD Blaster ignition coil and plug wires.�

S.U. carburetors rebuilt by Huffaker Engineering. �

K&N air filters.�

Winners Circle "Super" oil pan.�

Accusump oil accumulator. �

Remote oil filter. | �

| Cooling: | �Ron Davis dual-pass aluminum radiator. �

Modified aluminum water pump (with every other vane removed.) �

16-row aluminum oil cooler. | �

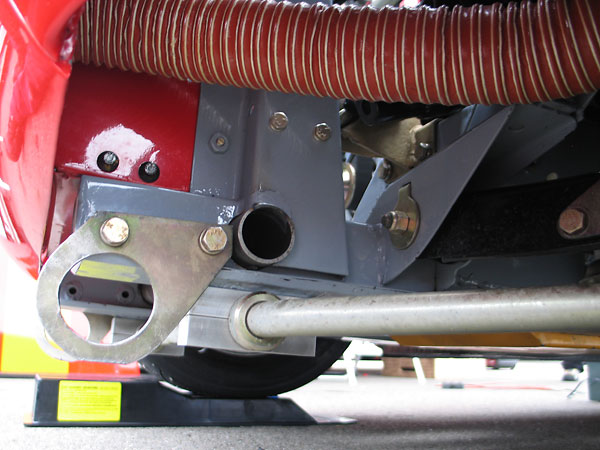

| Exhaust: | �Huffaker Engineering stainless steel through-the-tunnel exhaust system.�

(The header is a "long center branch" design, with specially selected diameters and lengths.)�

Megaphone (open) or Magnaflow muffler, depending on the noise requirements of the particular track.�

(Note: a Magnaflow stainless muffler was installed when we viewed the car at Watkins Glen.) | �

| Transmission: | �Taylor Race Engineering rib-case 4-speed dog-ring gearbox with �

1.83:1 first gear and 1:1 fourth gear. Quartermaster flywheel. �

Tilton 7.25" single disc clutch. Stock driveshaft. | �

| Rear Axle: | �Spridget axle housing. 4.22:1 gears mounted to a Tran-X limited slip differential�

(except when racing at Savannah, where 3.90:1 gears and a welded axle are used instead.) | �

| Front Susp.: | �550lb/in coil springs.�

Armstrong lever arm shocks modified by Apple Hydraulics.�

Steering arms modified to reduce bump steer. �

Winners Circle 7/8" anti-sway bar, mounted on aluminum pillow blocks and �

connected with 3/8" Heim joints. | �

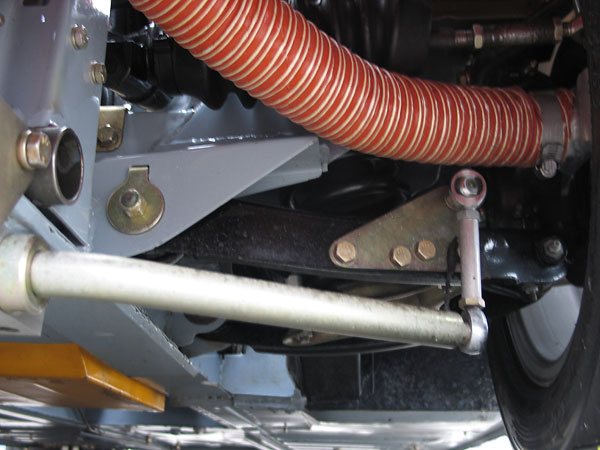

| Rear Susp.: | �Gullwing (offset) semi-elliptic leaf springs. �

Armstrong lever arm shocks with Heim joints.�

5/8" anti-sway bar (which isn't used all the time!)�

Watts linkage for lateral axle location.�

A radius rod to the body eliminates axle rotation. �

(Note: dual anti-tramp bars were installed when we viewed the car.) | �

| Brakes: | �(master) Girling dual master cylinders with Tilton remotely adjustable bias bar. � (front) stock rotors and calipers. � (rear) stock drum brakes. | �

| Wheels/Tires: | �Panasport Racing 13x6 aluminum wheels with Toyo Proxes R888 185/60R13 tires. | �

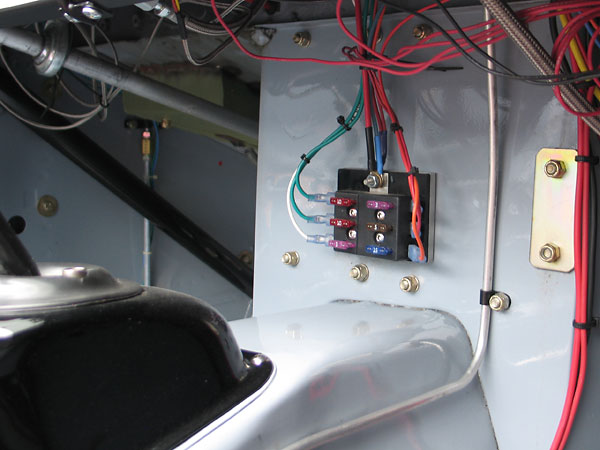

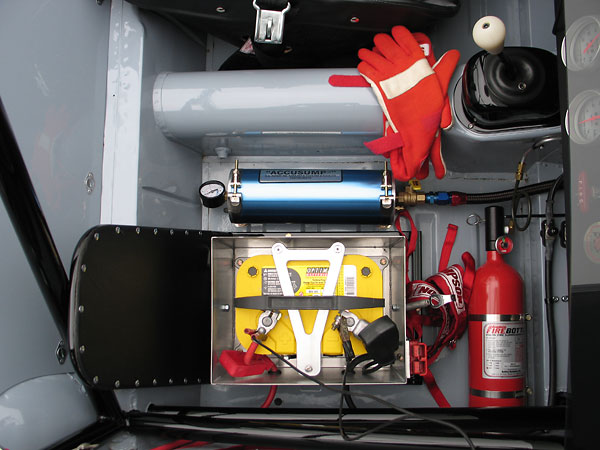

| Electrical: | �Odyssey "Yellow Top" battery.�

TSI gear reduction starter. | �

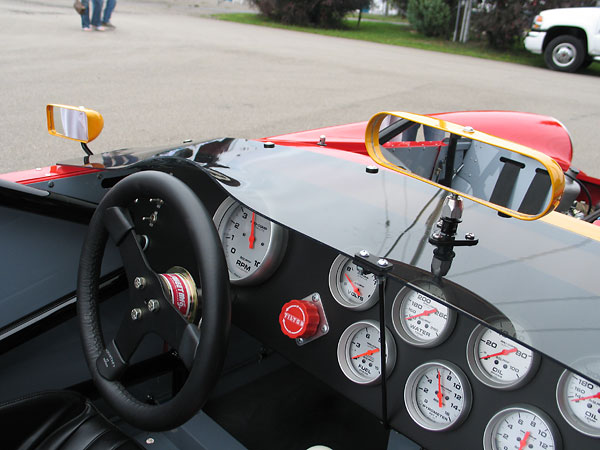

| Instruments: | �AutoMeter Ultra Light gauges (left to right) �

tachometer (0-9000rpm), �

voltmeter (8-18V), �

fuel pressure gauge (0-15psi), �

coolant temperature gauge (100-280F), �

pyrometer gauge (1 of 2, 0-1600F),�

oil pressure gauge (0-100 psi),�

pyrometer gauge (2 of 2, 0-1600F), �

oil temperature gauge (100-280 F). | �

| Fuel System: | �ATL 8-gallon fuel cell.�

Facet fuel pump.�

Holley fuel pressure regulator. | �

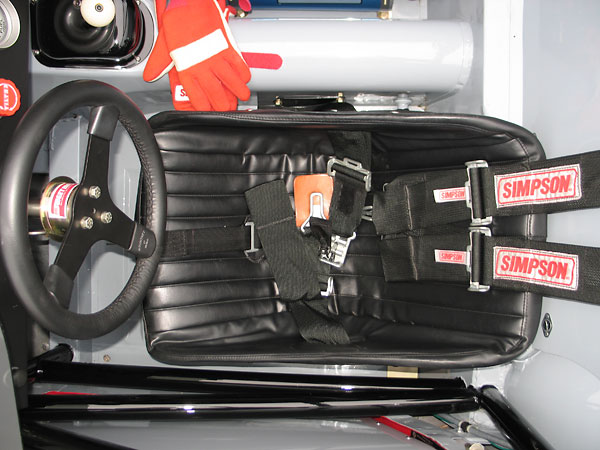

| Safety Eqpmt: | �Simpson 5-point latch-and-link safety harness.�

Sweet Manufacturing splined, quick release hub (part# 801-70055), mounted on �

a Mountney "GT" steering wheel.�

Firebottle centralized fire suppression system. | �

| Weight: | �1435#. | �

| Completion: | �2005. Has raced about four times per year since 2005, with a podium finish �

in every race of the last two years. | �

| Racing Class: | �SVRA Group 1, F-Production | �

| Comments: | �John has built four Spridget race cars over the years. This one was a street car that had sat for �

several years waiting to be restored. A college kid decided that he didn't have the knowledge or �

desire to complete the project, but it was a really solid car. John sold all the extra parts in �

an amount equal to what he paid for the project.�

� Several changes are being made in preparation for the 2010 racing season, including: � (1) redoing rear suspension tie points so the rear sway bar will work with through-the-tunnel exhaust, � (2) rolling the fenders out about 1 inch, front and rear, to gain more tire clearance, � (3) rotating the driver's seat to a more upright postion for better feel, � (4) raising the rollbar to suit the new driving position, and � (5) switching to Hoosier T.D. bias ply tires. � | �

�

�

�

�

�

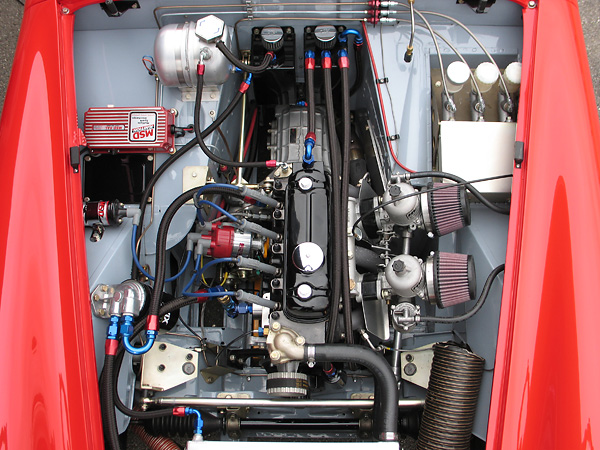

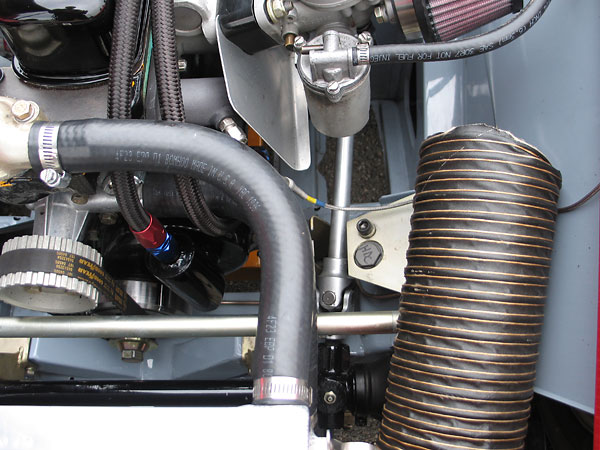

Engine Installation

��

�

1275cc Spridget engine with 0.040 overbore, JE forged pistons and Carrillo rods.

�

�

Unusual T-shaped engine steady bar.

�

�

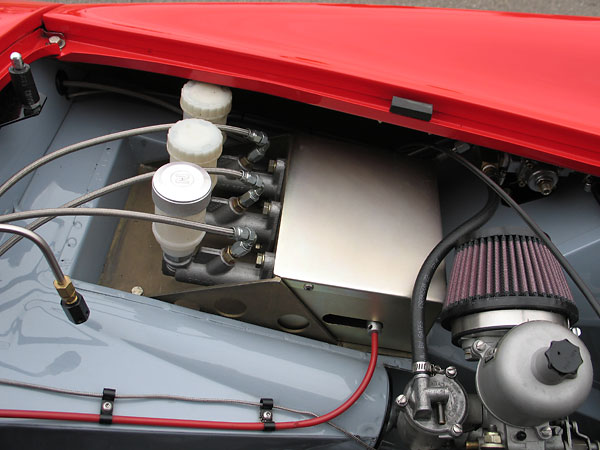

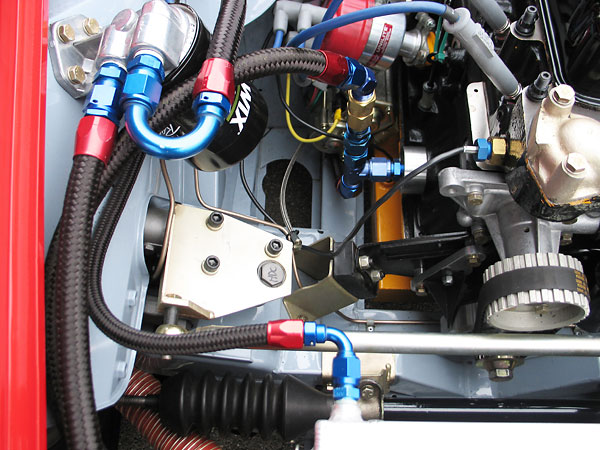

Girling dual brake master cylinders with Tilton remotely adjustable bias bar mechanism.

�

�

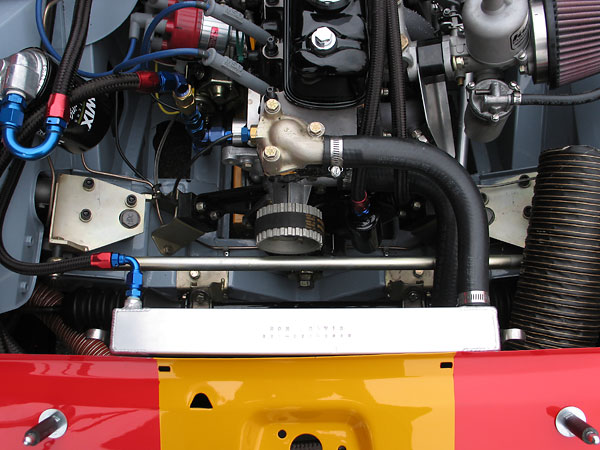

S.U. carburetors rebuilt by Huffaker Engineering. K&N air filters.

�

�

Ron Davis dual-pass aluminum radiator.

�

�

Two spring-loaded clips hold the radiator in place. It can be removed and replaced in minutes.

�

�

Airflow is prevented from bypassing the radiator core by this black, painted, aluminum shield.

�

�

Every second water pump impeller vane has been removed to slow coolant flow and prevent cavitation.

�

�

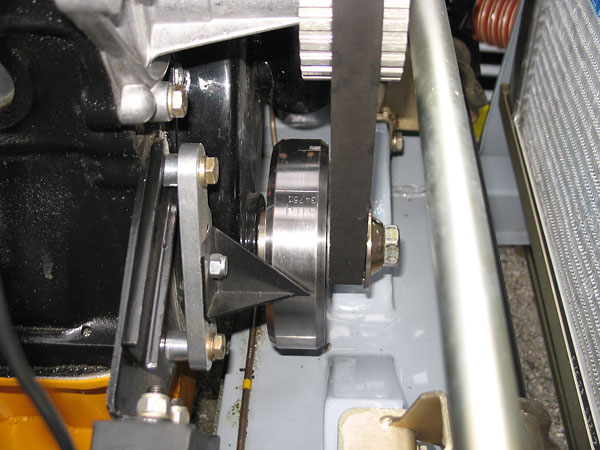

To provide improved access to the balancer, a V-shaped cut-out was made in the front crossmember.

�

(The new metal added back in is significantly thicker gauge than what was removed.)

�

The timing pointer is mounted to a bracket Huffaker Engineering makes for a crank-fired ignition sensor.

�

�

After V-notching the front crossmember, more strength was gained by fitting a Monte Carlo bar.

�

(That's what the pony car crowd calls a brace that spans from one front shock tower to the other.)

�

�

Notice the high capacity oil pan with side extensions. It has trap doors and a windage tray to

�

keep oil away from the spinning crankshaft, to prevent oil aeration and improve power.

�

�

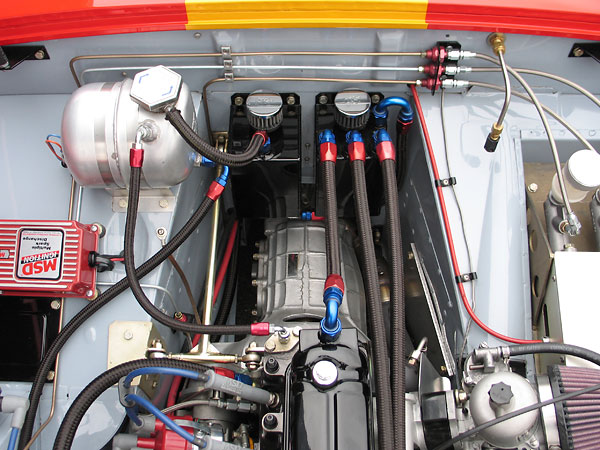

Mallory Unilite breakerless (optical sensor) distributor.

�

�

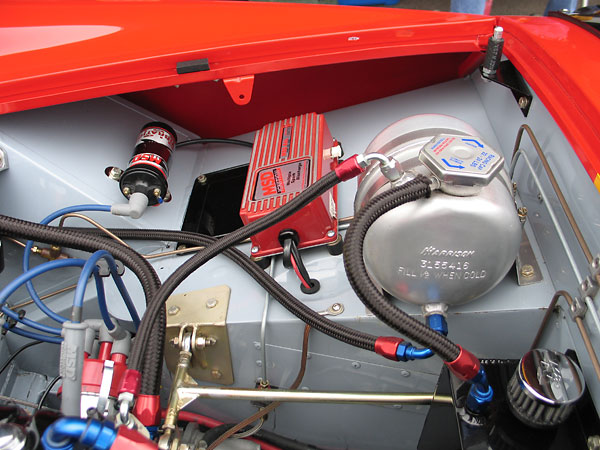

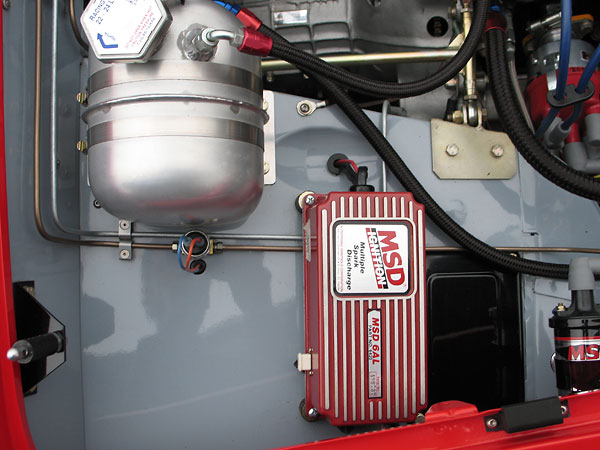

Harrison coolant header tank.

�

�

MSD: Multiple Spark Discharge ignition controller.

�

�

At Watkins Glen, the rev limiter feature of the MSD6AL ignition system was "chipped" at 8500rpm.

�

�

Coolant catch tank (left) and oil system breather tank (right).

�

�

Taylor Race Engineering rib-case 4-speed dog-ring gearbox with 1.83:1 first gear and 1:1 fourth gear.

�

Suspension

��

�

Oil cooler and brake cooling duct grilles in the front apron.

�

�

Tubular reinforcement of front structure.

�

�

Tow eyes.

�

�

7/8" anti-sway bar with aluminum pillow blocks and 3/8" Heim joints.

�

�

By class rules, the car is obliged to use stock front brake rotors and calipers.

�

�

Brake cooling ducts help fend off brake fade.

�

�

ATL fuel cell. (Note: the tailpipe reveals that the engine has been tuned to run on the lean side.)

�

�

A Magnaflow stainless steel muffler was installed when we viewed the car at Watkins Glen,

�

but isn't required or used on tracks with more liberal sound rules.

�

�

Anti-tramp bars were installed when we viewed the car, but they've subsequently been replaced

�

with a single radius rod to the differential housing.

�

�

Aluminum lowering blocks.

�

�

Watts linkage for lateral axle location.

�

�

Armstrong lever arm shocks, installed with Heim jointed linkage.

�

�

Gullwing (offset) leaf springs from The Winners Circle accommodate wide wheels and tires.

�

These springs are most popular for vintage racing, where class rules prohibit fender flares.

�

If the wide tires could be placed further outboard, straight leaf springs would be used.

�

�

These springs have a significantly lower spring rate than stock leaf springs, so they provide less

�

resistance to "tramp" or "wrap". Some sort of radius rods are needed to supplement the springs.

�

�

Panasport Racing 13x6 aluminum wheels.

�

�

Toyo Proxes R888 185/60R13 tires. For 2010, John is switching to bias ply tires because they're more

�

forgiving. He believes the radials are faster, but they break away quickly and without warning.

�

�

Interior

��

�

John molded his own low profile windscreen. Note also the Tilton remote brake bias adjustment knob.

�

�

Mountney GT steering wheel, installed on a Sweet Manufacturing quick release hub (PN: 801-70055).

�

�

AutoMeter Ultra Light gauges (left to right), voltmeter (8-18V), fuel pressure gauge (0-15psi),

�

coolant temperature gauge (100-280F), pyrometer gauge #1 (0-1600F), oil pressure gauge (0-100 psi),

�

pyrometer gauge #2 (0-1600F), and oil temperature gauge (100-280 F).

�

�

Simpson 5-point latch-and-link safety harness.

�

�

Aluminum door panel. Note also that the door latch has been replaced with simpler mechanism.

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

�

Footbox and pedals.

�

�

6-position fuse block.

�

�

Power and ground studs.

�

�

Firebottle centralized fire suppression system.

�

�

Since the Accusump oil accumulator is within reach, it's operated manually instead of via solenoid valve.

�

Optima "Yellow Top" battery. The battery box lid is padded because it's a "passenger seat", per class rules.

�

�

Engine "kill" switch. (Disconnecting the battery is sufficient since there's no alternator.)

�

�

Exterior

��

�

John McCue finished second overall in the Group 1 feature race of the 2009 U.S. Vintage Grand Prix

�

at Watkins Glen. His 2:22.972 lap time represents a very impressive average speed of 85.6mph

�

around the challenging 3.4 mile circuit.

�

�

A great team: John's pit crew consists of Lydia McCue and Larry Born.

�

Back home, John's friend Laury Simpson does much of his machine work.

�

�

One sign of an exquisitely well-prepared race car is that the crew has plenty of time

�

for relaxing activities like polishing the paint and brightwork.

�

�

Who can resist such a cheeky grin!

�

�

Dzus quarter-turn fasteners are both lighter and more secure than the original boot latch.

�

�

All photos shown here are from September 2009 when we viewed the car at The US Vintage Grand �

Prix at Watkins Glen. All photos by Curtis Jacobson and Don Moyer for BritishRaceCar.com, copyright 2010. �

All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Harry Gentry '62 MG Midget | �

| �

Rick Haynes '65 MG Midget | �

| �

Chuck Pitt '68 Spridget | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�