�

�

Ken Williamson's 1968 MGC GTS "Sebring" Racecar

� � Owner: Ken Williamson� City: Bellefonte, Pennsylvania

� Model: 1968 MGC GTS

� Engine: BMC 2.9L six-cylinder

� Prepared by: owner �

�

Extension of the MG Model Range

��

MG built sports cars in the charming market town of Abingdon,�

about seven miles south of Oxford and 45 miles west of London. In 1966, Abingdon's production�

was divided over five models which parent company British Motor Corporation marketed under two�

different marque names. MG employees had been assembling Austin Healey brand cars alongside MG�

models for about nine years. The Austin Healey 3000 was the top of line, but it was also long�

in the tooth. Sales were declining. Styling was beginning to look dated. Its body-on-frame�

construction was out of line with the factory's other models; all the other cars featured unibody�

construction. Major investments would be required to keep the Austin Healey 3000 in production,�

firstly because of looming safety regulations and secondly because the C-series engine used in�

the 3000 would soon be discontinued in other British Motor Corporation vehicles. The big Healey's�

days were clearly coming to an end. A replacement was needed.�

�

The MGC was conceived as a premium-priced, six-cylinder variant of the extremely popular MGB.�

There were already two distinct versions of the MGB: the MGB convertible had been introduced in�

1962 and the MGB GT (coupe) had been in production since 1965. Both the MGB convertible and the�

MGB GT came with 1.8 liter four-cylinder engines. The MGC represented an extension of the MG�

range into higher horsepower and price classes.�

�

The MGC project ultimately proved unsuccessful because British Motor Corporation didn't have a�

suitable engine. BMC planned on a brand new six-cylinder engine to be shared between the MGC�

and an Austin 3-liter saloon. It would be based loosely on the "Blue Streak" engine already used�

by the company's Australian subsidiary, which in turn was derived from the B-series four-cylinder.�

The Longbridge engine designers expected that thin-wall casting technology would facilitate making�

the new engine substantially lighter than either the C-series or the Blue Streak. Although thin-wall�

technology did allow closer spacing of cylinders for a shorter overall length, they missed every�

weight target. When a prototype engine finally arrived at Abingdon, it was at least 70 pounds heavier�

than promised. The MGC's 2.9L six-cylinder weighed 567 pounds - about 207 pounds more than a regular�

MGB engine - and incidentally about 249 pounds heavier than the Rover 3.5L V8 �

which was later used in the MGB GT V8 model. They missed their power objectives too. Much of the�

blame for this has been assigned to the engine's too-conservative seven main bearing crankshaft.�

(C-series engines had four main bearings.) A bigger problem was that the engine had an unfavorable�

bore-to-stroke ratio, carried over exactly from the C-series engine. �

�

The engine's height and weight meant a new front crossmember and new front suspension were�

required. Other differences: larger radiator mounted farther forward, bigger brakes, bigger�

wheels and tires, and a different steering rack ratio to ameliorate higher steering effort�

(at the expense of a larger turn radius). One styling change made the MGC easy to spot:�

a bulged bonnet with a smaller blister for the forward carburetor. Bottom line:�

the MGC was about 340 pounds heavier than a comparable MGB and it arrived at a budget-breaking�

cost. In contrast to the MGB and the Midget models, which were produced for eighteen and�

nineteen years respectively, MGC production spanned less than three. Abingdon ceased production�

of MGC sportscars in August 1969.�

�

Abingdon Production in the MGC Era

�| AH 3000 | MGB | MGB GT | MGC | MGC GT | MGC Notes | |

| 1966 | 5495 | 22675 | 12510 | 9 | 4 | (prototypes) |

| 1967 | 3051 | 15128 | 11396 | 82 | 38 | (pre-production) |

| 1968 | 1 | 17355 | 8352 | 2596 | 2491 | MGC total: 5087 |

| 1969 | 0 | 18887 | 12135 | 1757 | 1925 | MGC total: 3682 |

| (MG Midget and Austin Healey Sprite production figures omitted from table for clarity.) | ||||||

�

�

�

�

�

The MGC GT Sebring Racecars

��

In the automotive industry, it's important for new models to make strong first impressions.�

BMC sought to promote their new MGC model through endurance road racing. Specifically,�

the BMC Competitions Department set its sights on the annual twelve hour endurance race at�

Sebring Florida. Perhaps recognizing that the MGC's engine would have a power disadvantage in�

any racing class the car was eligible to enter, the "Comps" team sought to make up for it�

by reducing weight.�

�

Specially fabricated aluminum body panels were ordered for the MGC "GTS" or "Sebring" racecars.�

Most of these panels were made on regular production press dies by supplier Pressed Steel.�

Fenders were a conspicuous exception: they were hand-made and they featured aggressive fender�

flares to suit oversized tires. The following bolt-on panels were made from aluminum instead�

of steel: front valance, front fenders, doors skins, and GT hatches. (Aluminum bonnets were�

already standard equipment.) Aluminum rear fender flares were riveted onto modified steel�

quarter panels, and the rivets were hidden under body filler and paint. Aluminum roofs were�

also riveted and glued on. However, the underlying structure of the MGC GTS bodyshells remained�

essentially stock because these were unibody cars. Strength and stiffness were achieved by�

spreading stress through spotwelds into thin sheetmetal. Regular mass-produced steel parts�

were used for most of the cars' structural core: floorpans, transmission/driveshaft tunnels,�

crossmembers, rocker panels (inner and outer), firewalls, inner wings, rear wheel wells, the�

heelboards behind the seats, and of course the subframe sections that ran underneath the floorboards.�

�

�

ARE YOU ENJOYING THIS ARTICLE? WANT MORE?

�

BritishRaceCar.com will have to cut back plans for continued growth if we can't find more financial support.

�

If you like what you've found here, and you want to see more, please click here and follow the instructions.

�

Readers like you keep BritishRaceCar.com online and growing through voluntary financial contributions.

�

�

Weight reductions weren't limited to the bodywork. For example, aluminum alloy engine blocks�

and cylinder heads were specially cast to save weight compared to the iron blocks and heads�

used on production cars. The Comps team only used an aluminum MGC engine block once (see�

below) and the results weren't good, but the aluminum heads worked out much better.�

�

How many sets of aluminum Sebring panels were made? By all accounts, enough for six complete�

cars plus some spare parts.�

�

Only two MGC GTS racecars were ever raced by the Comps Department.�

�

A fascinating wrinkle in the GTS story is that the first GTS racecar debuted with a four cylinder�

engine and a regular MGB bonnet because the upcoming MGC model was still a well-guarded secret.�

The occasion was the 1967 Targa Floria endurance race in Sicily. Sadly, it finished far enough�

behind the winner that its results weren't officially classified. Updated with a six-cylinder engine�

and MGC style bonnet, this same car was entered at Sebring in 1968 and 1969. These were tumultuous�

years for MG and for the Comps Department. A corporate takeover had thrown their futures into doubt.�

In 1969, "British Leyland Motor Corporation" was the official entrant name when MGC GTS racecars�

were entered in the Sebring Twelve Hour race. This was the last "works" race entry for the MG marque.�

| VIN No. / UK Reg. No. | �

1967 Targa Florio (720km) 62 started, 22 finished | �

1968 Sebring (12hr) 68 started, 22 finished | �

1968 Marathon de la Route (84hr) 59 started, 26 finished | �

1969 Sebring (12hr) 70 started, 35 finished | �

| ADO52-1060 MBL-546E (nickname "Mabel") | �

not classified¹ Drivers: P.Hopkirk & T.Mäkinen Racing#: 230 | �

10th (32 laps down) 1st in Class 11² Drivers: A.Hedges & P.Hopkirk Racing#: 44 | �

6th (28 laps down) Drivers: A.Hedges, T.Fall, & J.Vernaeve Racing#: 4 | �

34th (70 laps down) 6th in Class 11 Drivers: B.Brack & C.Hill Racing# 36 | �

| ADO52-1059 RMO-699F (nickname "Romeo") | �

� | � | DNF (head gasket) Drivers: R.Enever, A.Poole, & C.Baker Racing#: 5 | �

15th (44 laps down) 5th in Class 11 Drivers: A.Hedges & P.Hopkirk Racing# 35 | �

�

After the 1969 Sebring 12 Hour race, the Comps Department sold ADO52-1060 and ADO52-1059 in America�

at an advertised price of $4500 each (including spare engine, transmission, and rear axle) instead�

of shipping them back to England. The two cars remain intact and un-raced in private collections.�

Since the mid-1980s, due to considerable public interest, both of the original cars have appeared�

in magazines and in public events. Their provenance and identities are undisputed. �

�

After disappointing race results at Sebring in 1969 and in light of pending discontinuation of MGC�

production, an executive decision was made to liquidate inventory of GTS bodies and attendant spare�

parts held at Abingdon. A British racer and well known Healey enthusiast named John Chatham bought�

the entire inventory. Chatham quickly went to work building up one MGC GTS racecar for himself.�

With co-driver Alan Harvey, he raced his MGC GTS (U.K. registration VHY-5H) in the 1970 Targa Florio�

to a 39th place overall finish. Chatham built a second MGC GTS bodyshell into a street car (U.K.�

registration EHW 441K) for his friend and fellow enthusiast Bill Gardner. It was later sold to Steve�

Bicknell. Then, Chatham built a third street legal MGC GTS (U.K. registration VHW-330H) for�

Alan Zafer who worked in media relations for British Leyland at Abingdon. Chatham's biography�

(Mr. Big Healey: The Official Biography of John Chatham by Norman Burr) mentions that�

Zafer's car used some parts from a cannibalized production MGC GT due to limited stock of aluminum�

panels. Starting in 1971, John Chatham started to build a final especially lightweight MGC GTS�

racecar for British "Modsports" racing in 1972 and 1973. Using one of the special aluminum�

engine blocks set four inches further back in the chassis, this car set a three-lap record at�

Silverstone (1:54 per lap). �

�

All six of the MGC GTS racecars mentioned to this point in the story still exist. In fact, all�

six of them appeared together during an MG Car Club meeting at Silverstone in May 1992.�

�

�

�

The M.G. Car Company Ltd., Abingdon - on - Thames, England.

�

When ordering replacements quote car number ADO52/1061.

�

The Mystery of the Seventh MGC GTS

� �

In late 1979 an English racer and MG enthusiast named Graham Wiseman learned�

from a friend that a scrapyard in San Jacinto, California had acquired what might be one�

of the original MGC GTS racecars. At that time, the locations and even the VIN numbers of�

MBL-546E and RMO-699F weren't widely known. Wiseman traveled from England to San Jacinto to�

investigate. The car he discovered was well picked over, but it had some distinctive parts�

such as an aluminum GT hatch. Wiseman purchased what he could. He reportedly shipped about�

80 parts back to England including a windshield w/Sebring stickers still attached, a�

chassis plate bearing VIN number ADO52-1061, and the slam panel that the chassis plate was�

riveted to. The iconic MGC GTS aluminum flared fenders were not retrieved. Neither was the�

aluminum cylinder head. In a box of parts that had been with the car, Wiseman reportedly�

found an oil damaged log book showing ADO52-1061 and U.K. registration RMO-699F. From this,�

he initially assumed he had found the remains of the car Paddy Hopkirk and Andrew Hedges�

had driven at Sebring in 1969. �

�

Indeed, Paddy Hopkirk and Andrew Hedges may have driven ADO52-1061. If they did so, it would�

have been in practice sessions for the big race. Having a back-up or practice car for a major�

race is certainly not unheard of. Transferring log books and registration numbers�

between racecars on a works team was common practice, so ADO52-1061 may have worn the registration�

number RMO-699F concurrently or even before the car that actually raced at Sebring. However,�

there is no substantive evidence that the car Wiseman found in a California scrapyard was ever�

raced by the Comps team. Frankly, there's little evidence of a back-up MGC GTS being at Sebring.�

To our knowledge, no one has ever published a photograph of all three MGC GTS racecars in one�

location, either at Sebring or at Abingdon.³ �

�

After returning home to Sommerset England, Graham Wiseman acquired an MGC GT and began�

preparing it as a Sebring replica. He installed fiberglass fender flares and rear hatch�

and full fiberglass doors. Wiseman cut into the bodyshell's cowl vent plenum so that he�

could mount the MGC engine about six inches further back in the chassis than the engines�

in either MBL-546E or RMO-699F. In lieu of triple Weber 45DCOE carburetors as the original�

MGC GTS racecars used, Wiseman installed three Dell'Orto carburetors. Wiseman's MGC GT was�

painted to replicate RMO-699F as raced at Sebring. On the basis of the chassis�

plate and the log book he had retrieved from California, Wiseman applied for and was�

granted rights to use the RMO-699F registration number. He later surrendered that number�

so that it could be used by the current owner of ADO52-1059.�

�

Graham Wiseman sold his ADO52-1061 to a dealer in the late 1980s. The car was shipped to U.S.A.�

and was sold at auction by Christies of New York. Derek Durst of Rhode Island, David Dexter�

of Massachusetts, and Tony Giordano of New York have subsequently owned the car. Since 2003, Ken�

Williamson of Pennsylvania has owned the car. Of its owners, Ken has been most committed�

to preparing and driving it as a vintage racecar. Many of his modifications, such as installing�

Weber 45DCOE carburetors, have moved the car closer to authentic MGC GTS specifications.�

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

Features and Specifications

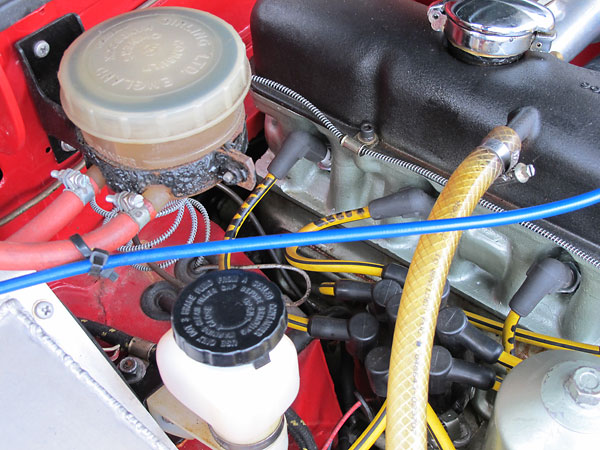

�| Engine: | �BMC 2.9L six-cylinder engine built by Dennis at DL Automotive & Performance in State College PA.�

Standard MGC crankshaft, reworked.�

Pauter connecting rods.�

JE forged pistons (0.040" over).�

Iron cylinder head flowed and ported by Ryan at Shady Dell Speed Shop in State College PA.�

Head shaved 0.050" for about 11:1 compression ratio when used with Fel-Pro composite head gasket.�

ARP high tensile strength cylinder head studs.�

English Ford V6 valves.�

Bronze valve guides.�

Custom ground camshaft by Delta Camshaft of Tacoma WA.�

Iskenderian valve springs and pushrods.�

Alloy valve spring retainers.�

(Note: Ken usually shifts at 5,500 to 6,000rpm, depending on how hard he's driving.)�

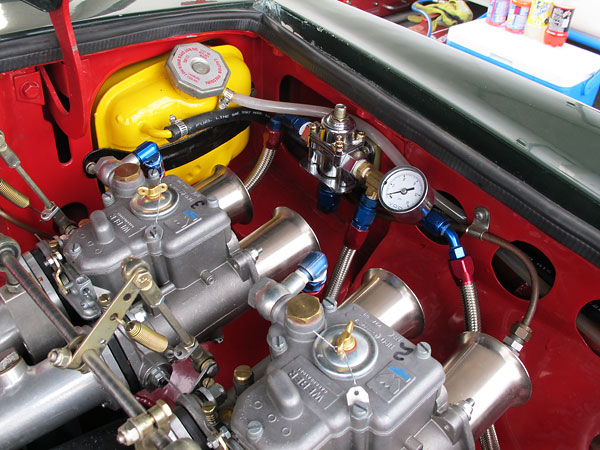

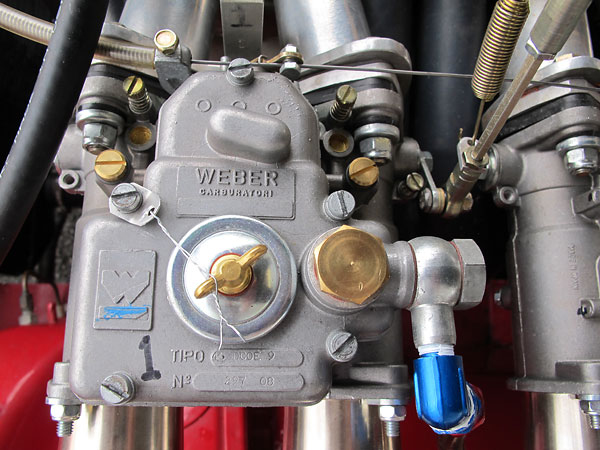

Triple Weber 45DCOE carburetors.�

Lucas distributor with Pertronix Ignitor breakerless module.�

Lucas Sport (gold) ignition coil.�

Lucas spark plug wires.�

Custom modified oil pan. | �

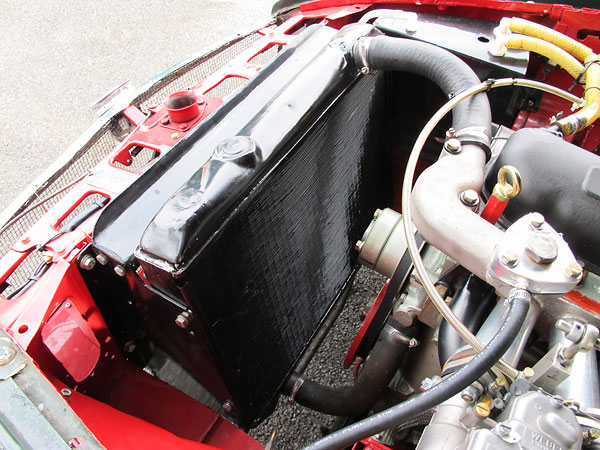

| Cooling: | �copper and brass radiator.�

Mocal 13-row oil cooler. | �

| Exhaust: | �Downton Engineering 6-2-1 tubular header. | �

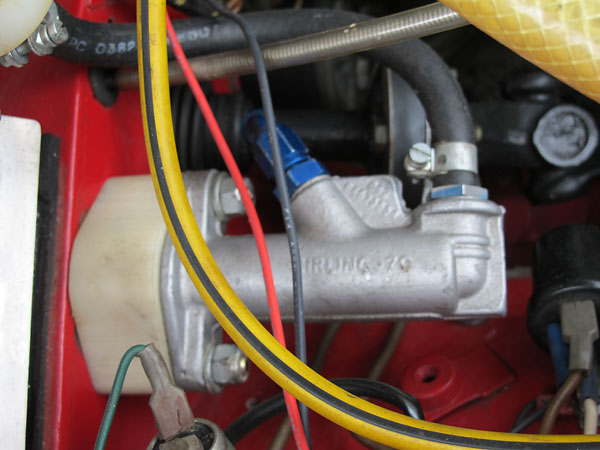

| Transmission: | �straight-cut, close-ratio, four-speed manual transmission.�

Laycock electrically-engaged overdrive.�

Lightened flywheel.�

AP competition clutch and pressure plate.�

Girling slave cylinder. | �

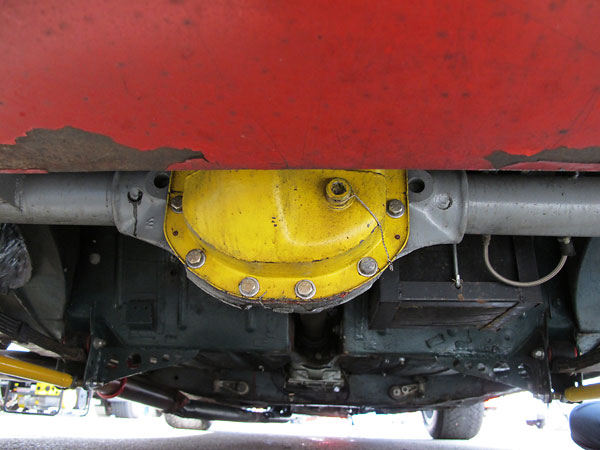

| Rear Axle: | �Salisbury axle.�

3.70:1 ring and pinion.�

Quaife limited slip differential. | �

| Front Susp.: | �uprated torsion springs.�

Spax adjustable gas pressurized telescoping shock absorbers.�

7/8" anti-sway bar mounted on aluminum pillow blocks. | �

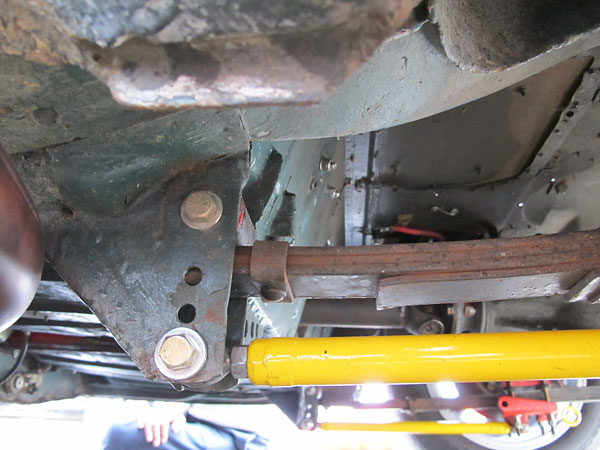

| Rear Susp.: | �leaf springs.�

Spax adjustable gas pressurized telescoping shock absorbers.�

Anti-tramp bars. | �

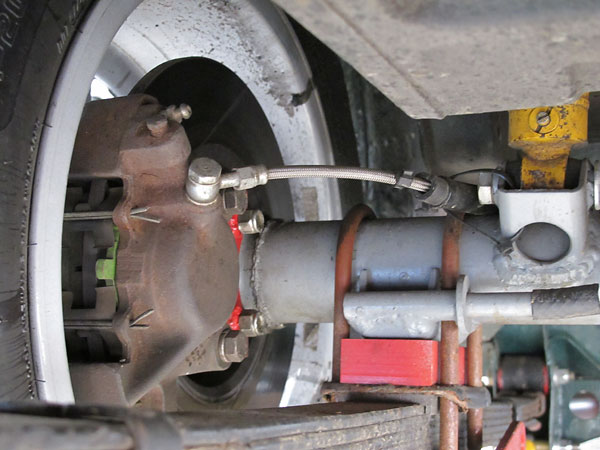

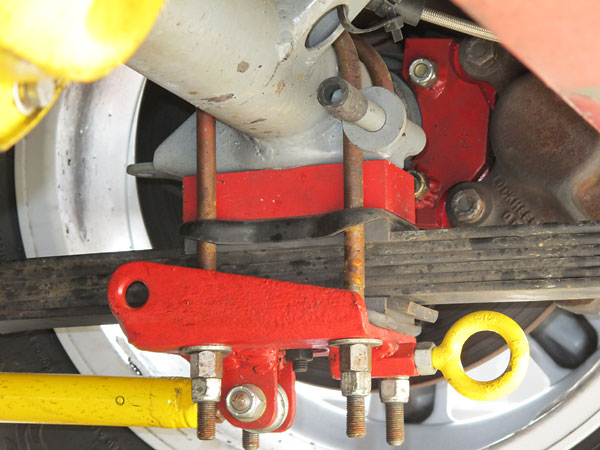

| Brakes: | �(master) dual Girling master cylinders with adjustable bias bar and remote reservoir. � (front) Lockheed MGC 2-pot iron calipers and cross-drilled Brembo solid rotors. � (rear) Lockheed MGB 2-pot iron calipers and Brembo solid rotors. Jamar Park-Lok line lock. | �

| Wheels/Tires: | �Minilite 8Jx15 eight spoke alloy wheels.�

Hoosier Speedster P205/60R15 racing tires. | �

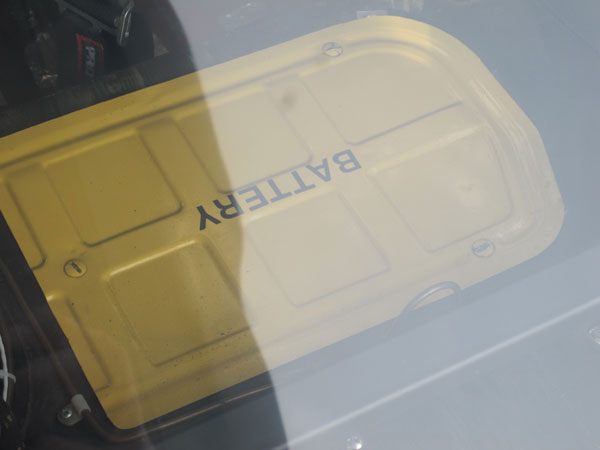

| Electrical: | �single 12V lead-acid battery.�

Lucas alternator.�

Gear reduction starter.�

Joseph Pollak battery disconnect switch. | �

| Instruments: | �(left to right)�

Flight Data Systems FC-10 fuel computer (0.6-70 gallons per hour),�

Smiths dual oil pressure (0-100psi) and water temperature (90-230F),�

Smiths speedometer (0-140mph),�

Smiths tachometer (0-7000rpm),�

Smiths ammeter (-30 to 30 amps),�

Smiths fuel level gauge (E-F).�

| �

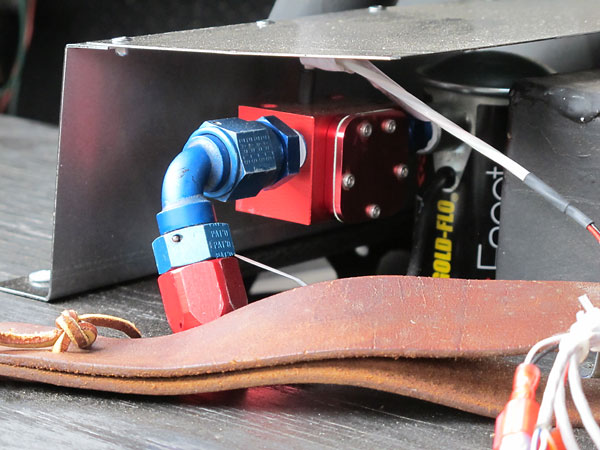

| Fuel System: | �ATL fuel cell.�

Facet Gold-Flo electric fuel pump.�

Flight Data Systems FT-60 transducer (to measure fuel flow rate).�

Holley adjustable fuel pressure regulator with VDO gauge (0-15psi). | �

| Safety Eqpmt: | �G-Force Pro Series five point cam-lock safety harness.�

Kirkey aluminum drivers seat.�

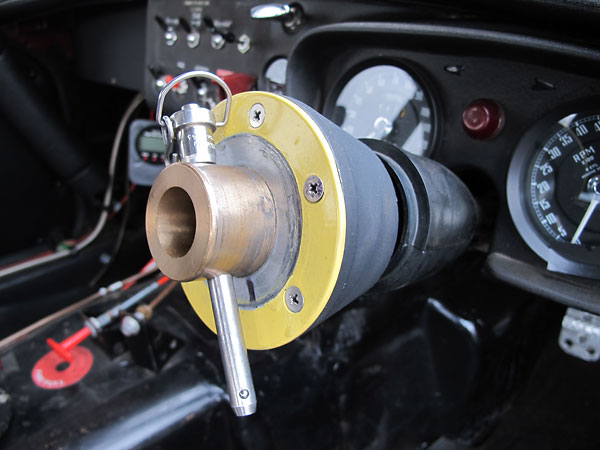

Moto-Lita steering wheel (installed backwards) on a quick release hub.�

Erskine Fire Ltd. fire suppression system. | �

| Class: | �SVRA C-Production | �

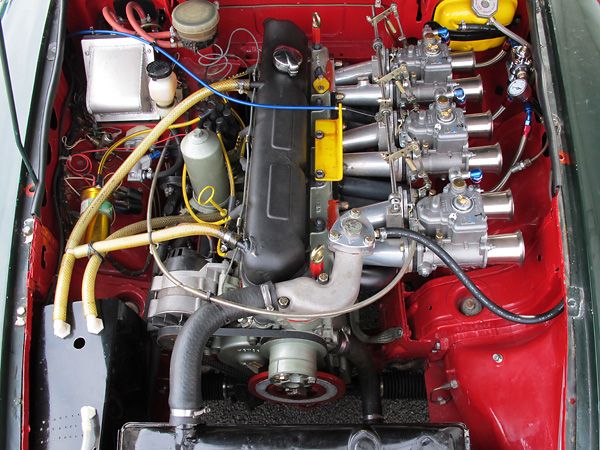

Engine Installation

��

�

Bore too small, stroke too long, valves too small, and deck too high.

�

Stock dimensions - 3.28" (83.3mm) by 3.50" (88.9mm) - produced 2912cc.

�

All production MGC engines started with a modest 9.0:1 compression ratio.

�

�

Holley adjustable fuel pressure regulator with VDO gauge (0-15psi).

�

�

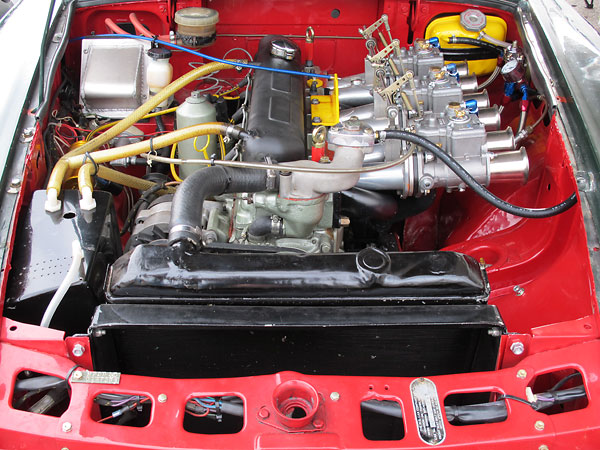

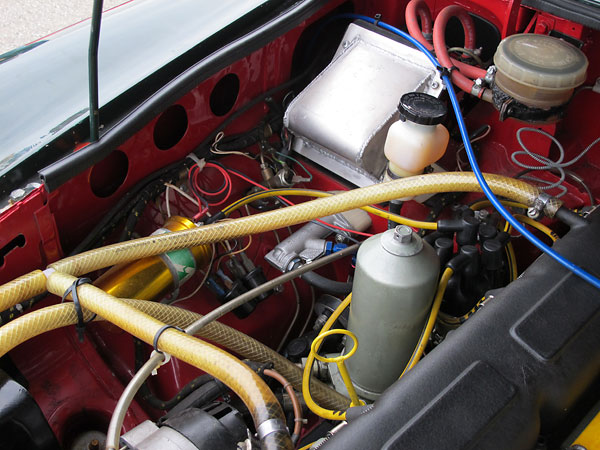

Fabricated intake manifolds.

�

�

Weber carburatori: Tipo 45 DCOE 9, Numero 297 08.

�

Jetting is the same as the works team used at Sebring.

�

�

John Chatham and Graham Wiseman did what the Comps Department probably wished it could have

�

done. They cut away the center section of the firewall, right back into the cowl vent plenum

�

so they could mount their engines further back in the chassis. As shown here, Wiseman

�

managed to install the MGC engine fully six inches rearward of its standard location.

�

�

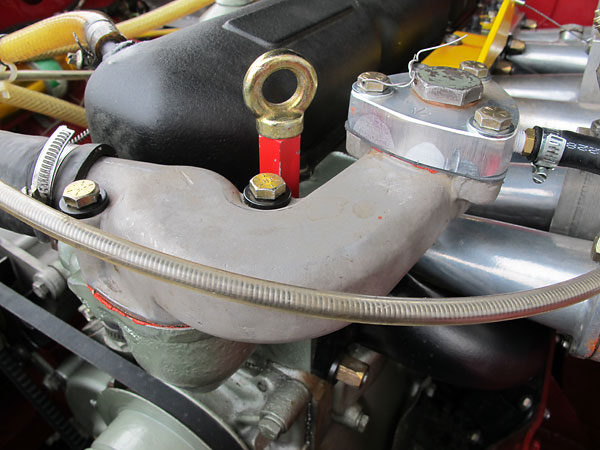

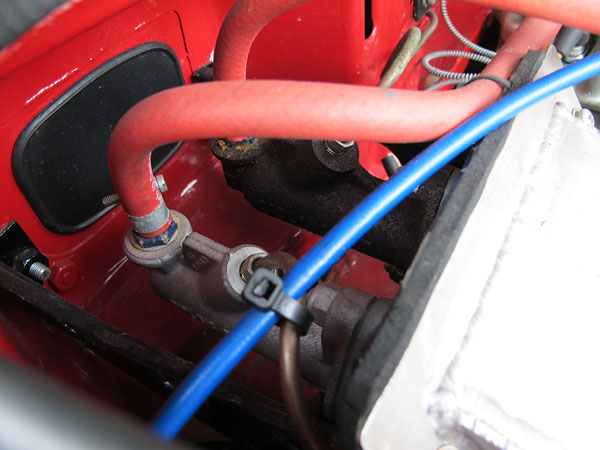

Thermostat housing. Normally, a pressure relief radiator filler cap would be installed at right.

�

On this racecar, that function has been relocated to a header tank on the firewall.

�

�

Copper and brass radiator.

�

�

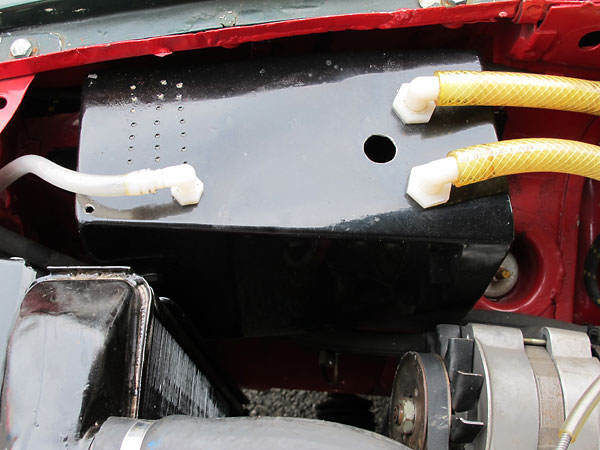

An inconspicuous but very interesting detail: the center portion of the slam panel is bolted into

�

place whereas original MGC slam panels are one continuous part from fender to fender. This

�

center section was apparently extracted from the car Graham Wiseman found in California.�

�

Removable slam panels are a popular feature on MGB V8 conversions. They facilitate removal and

�

replacement of the engine and transmission as a single assembled unit. Jim Stuart deserves

�

credit for popularizing the idea. Examples implementations may be seen here:�

1,�

2,�

3,�

and 4.

�

�

"XPDR NO 0197594" (Electronic transponders are used by automated timing and scoring systems.)

�

�

Mocal 13-row aluminum oil cooler.

�

�

Degree sticker for measuring ignition and valvetrain timing.

�

�

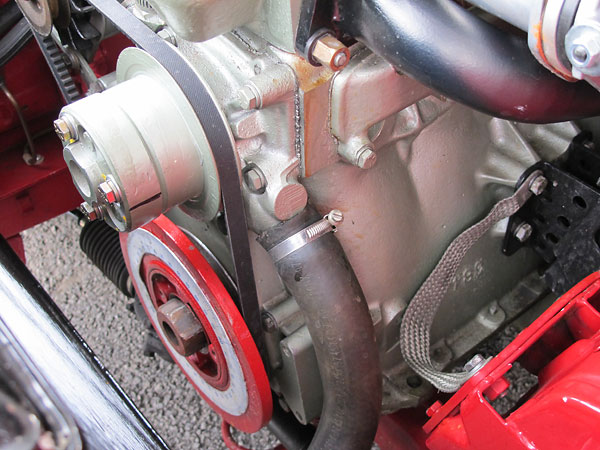

Lucas alternators with external voltage regulators first appeared on MG sportscars in 1968.

�

In 1969, MG switched from part number 23548 to part number 23716. Both parts were rated to

�

produce 34 amps, but the later design accomplished this with an internal voltage regulator.

�

�

MGC water pump.

�

�

Breather / overflow tank.

�

�

Lucas ignition coil. The original MGC GTS cars raced with two ignition coils installed

�

side-by-side so they could very quickly change coils in the event of a failed part.

�

(Ken has a works-style dual ignition coil bracket, but it's not currently installed.)

�

�

A custom fabricated aluminum cover for the brake master cylinders and bias bar mechanism

�

was designed by former owner Tony Giordano, and fabricated by Bob Aiken Motorsports.

�

�

Girling 0.7" bore clutch master cylinder. Its location is different from stock

�

because it's been moved to make room for a second brake master cylinder.

�

�

Dual Girling brake master cylinders: one for the front brakes and one for the rear.

�

�

Girling remote brake fluid reservoir.

�

�

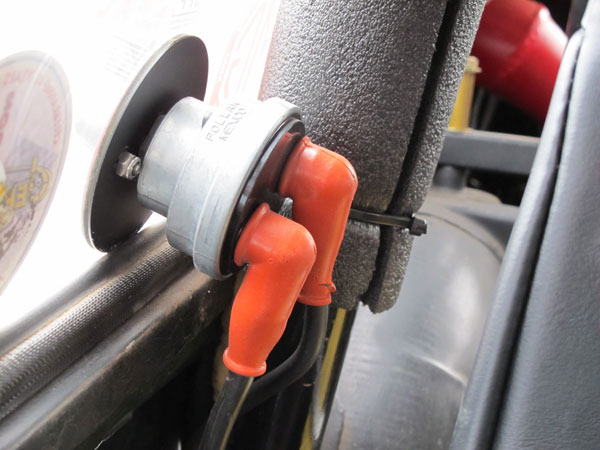

Lucas distributor. Two leads from its aluminum housing (one black and one red)

�

suggest that its breaker points have been replaced by an electronic module.

�

�

Fabricated tubular steel 6-2-1 exhaust header.

�

�

Header collector.

�

�

WHO PAYS THE BILLS AROUND HERE?

�

(1) Readers like you. -- Please take a moment to review our V.I.P. sponsor list.

�

(2) Businesses you should know about. -- Please review our vendor directory.

�

�

Chances are, you or your business should be on one of these two lists.

�

Find out how: -- Contribute To Our Operating Fund! -- Buy a Banner Ad!

�

Front Suspension

��

�

Aside from nuts and bolts, there are no common parts between MGB and MGC front suspensions.

�

MGC front suspensions used telescoping shock absorbers instead of lever shocks, and they used

�

torsion springs instead of coil springs. However, both designs utilize old-fashioned kingpins

�

instead of ball-joint mounted hub carriers.

�

�

7/8" front anti-sway bar mounted on aluminum pillow blocks.

�

�

Spax adjustable gas pressurized telescoping shock absorbers.

�

�

This is a green car with red overspray from when its engine compartment was re-painted. The first

�

MGC GTS racecar, MBL-546E, was initially painted BMC's signature Tartan red color. MBL-546E was

�

re-painted green before the 1967 Targa Florio race to differentiate it from Italian racecars. MBL-546E's

�

engine bay remains red to this day whereas RMO-699F's bay is and always was green.

�

�

The Comps Department used special Lockheed aluminum 4-pot brake calipers on the front, but for

�

the time being Ken is using regular MGC iron 2-pot calipers. Jaguar competition hubs are used

�

in lieu of regular MGC hubs; the splines are the same, but Jaguar hubs are thicker and stronger.

�

�

Stock MGC front suspension torsion bars were 9/16" diameter. Stiffer springs are available from

�

Moss Motors: 3/4" diameter for ~137 #/inch stiffness, 7/8" for ~228 #/inch, and 1" for ~382 #/inch.

�

Ride height may easily be adjusted at the torsion bar end stops. Background: modified MGC oil pan.

�

�

Rear Suspension

��

�

Stock Salisbury axle housing with back cover modified to increase lubricant volume.

�

�

Americans call them traction bars. Brits call them anti-tramp bars. Hot-rodders and drag

�

racers use them to control spring wind-up and pinion angle change off the line...

�

�

However, when you see horizontal links underneath leaf springs on a road-race car, they're usually

�

there to alter the suspension's behavior while cornering. Specifically, these links are installed

�

to cause or to increase the roll understeer characteristic of the rear suspension.

�

�

Spax adjustable gas pressurized telescoping shock absorbers. Production MGC GT cars were built with

�

lever shock absorbers, but the Comps Department installed telescopic shocks on the Sebring cars.

�

�

The Comps Department used aluminum Lockheed brake calipers from Jaguar's Mark 2 sedan model,

�

but they're scarce. For now, Ken is using regular MGB front brake calipers with Brembo discs.

�

The difference in unsprung weight is significant, and the MGB calipers are larger than needed.

�

�

1.25" thick aluminum blocks lower the rear ride height. Eyebolts for trailer tie-downs.

�

�

Interior

��

�

Toggle switches, top row from left to right: spot lights, roof i.d. light, wipers, windshield washer pump.

�

Second row, left to right: (unlabeled/spare), fan, lights, ignition (key), fuel pump (under switch guard.)

�

�

Lightened door hinges.

�

�

Side view mirror.

�

�

Lightened door strike plate.

�

�

Kirkey aluminum drivers seat with G-Force Pro Series five point cam-lock safety harness.

�

�

Instruments (left to right): Flight Data Systems FC-10 fuel computer, Smiths dual oil pressure and

�

water temp, Smiths speedometer, Smiths tachometer, Smiths ammeter, and Smiths fuel level gauge.

�

�

Moto-Lita steering wheel (installed backwards on its hub.)

�

�

This quick release steering wheel hub probably dates to the 1980s.

�

�

Here's something to double-check before going on track: a large pip pin secures the

�

steering wheel hub to the steering column, but the joint doesn't feature splines.

�

Many racing organizations expressly forbid this steering wheel attachment method.

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)

�

�

�

Ken purchased an original Comps Department gear selector knob with built-in electric overdrive

�

switch several years ago. That shifter knob is kept in safe storage, and he now builds and

�

sells authentic reproduction knobs. The knob shown here is one of Ken's reproductions.

�

�

Flight Data Systems' FC-10 fuel computer can display instantaneous fuel consumption rate (from

�

0.6 to ~70 gallons per hour) or alternatively can display fuel used or fuel level. Developed for

�

experimental aircraft, this gauge has limited utility for sprint races but it could be helpful

�

in enduros or rallies. A gauge like this might really help some of the NASCAR teams.

�

�

High-beam / low-beam selector. Turn signal flasher. Not so far removed from street use.

�

�

A convenient brace for the navigator's or riding mechanic's feet.

�

�

Jamar Park-Lok hydraulic line lock functions as a parking brake. To engage it, the driver

�

first steps on his brake pedal and then presses the Park-Lok button. The Jamar line lock

�

automatically disengages when the brake pedal is depressed again.

�

�

Generously padded passenger seat. Original MGC GTS cars raced with ordinary

�

production seats mounted on both driver and passenger side.

�

�

Original MGC GTS racecars came with aluminum doors. These are fiberglass. Fiberglass doors aren't a

�

major weight reduction over steel in and of themselves. Bigger gains were achieved by replacing

�

glass with acrylic and replacing heavy steel window regulators with simple aluminum guide bars.

�

�

Telescopic shock absorber mounting towers have been welded-in above the rear axle.

�

�

Flight Data Systems FT-60 transducer to measure fuel flow rate. Facet Gold-Flo electric fuel pump.

�

Original MGC GTS racecars utilized S.U. double-ended (Jaguar style) pumps mounted in a wheel well.

�

�

Erskine Fire Ltd. fire suppression system.

�

�

The fire suppression system can be actuated by either of two cables. One cable is for actuation

�

from the drivers seat. The second cable facilitates actuation by corner workers.

�

�

A single 12V lead-acid battery is mounted on the driver's side.

�

�

Joseph Pollak battery disconnect switch.

�

�

Exterior

��

�

Ken Williamson contests the MG Vintage Racer 2011 Collier Cup all-MG feature race at Watkins Glen.

�

(Photo by Donnie Moyer for BritishRacecar.com. Copyright 2012, All rights reserved.)

�

�

In the Collier Cup race, Ken Williamson circled the challenging 3.40 mile Watkins Glen

�

circuit with a best lap time of 2:39.339 for an average speed of 76.82 miles per hour.

�

(An MG Midget won that sprint race with a best lap time of 2:21.724 for 86.37mph.)

�

�

The MGC GTS cars weren't conceived as sprinters. Their strong suit was their capacity to sustain

�

high average speeds over many hours. Historically, their best performance was achieved in the

�

1968 Marathon de la Route 84-hour endurance race at Germany's Nürburgring. MBL-546E's

�

worn out brake pads welded to its rotors during a pit-stop in the 67th hour. Before that

�

delay, MBL-546E was running third. MBL-546E still managed to finish sixth overall.

�

�

MBL-546E suffered brake problems at Sebring in 1969. Canadian hero Craig Hill recalls that

�

his brakes faded quite early. He pitted, and the team pumped fresher brake fluid through

�

the system. An easily fixed problem, but it could just as easily have been prevented.

�

�

Racing number 35 is the number RMO-699F was assigned for the 1969 Sebring 12 Hour race.

�

Ken's MGC GTS is the only MGC racecar that's still actively raced in North America, but a

�

number of MGB GT and MGB GT V8 racers have chosen to replicate GTS styling features.

�

�

Polished aluminum trim panels over the rear fender flares are a unique feature of this

�

particular car. The original MGC GTS racecars were built with hand-made aluminum flares

�

with all seams filled-in and with the aluminum painted body color (i.e. British racing green.)

�

�

When race teams enter multiple cars in endurance races, it's customary to decorate them with

�

differentiating details. For example, RMO-699F's front valance was painted bright yellow

�

whereas MBL-546E's front valance was painted vivid red. Roof mounted marker lamps

�

were similarly color-coded to improve recognition of the cars during nighttime racing

�

�

Lucas sealed beam headlights under molded Perspex (acrylic) fairings.

�

�

At Sebring in 1969, MBL-546E had a leather hold-down strap at the front of its bonnet,

�

but RMO-699F didn't. The team had re-mounted RMO's bonnet with hinges at the front!

�

�

(Drivers) Ken Williamson, Capt. K.R. Williamson II, H. Paige Hope

�

(Sponsors) Castrol Oil. Dunlop Tires. "Quality Costs No More."

�

�

Automobile Racing Club of Florida decal. ARCF volunteers staffed the Sebring Twelve Hour race.

�

�

Stickers: United States Marines Corps, Vintage Racer Group, 2004 50th Anniversary of the Collier

�

Brothers Memorial Race, Pollak master disconnect switch, VRG 2009 Jefferson 500 at Summit Point.

�

�

LeMans style fuel filler cap.

�

�

"Curry Scarsdale" under the registration number: the Curry Auto Group operates car dealerships in

�

the New York City area. They specifically offer Chevrolet, Acura, Honda, and Subaru cars.

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

�

�

Genuine U.K.-produced Minilite 8Jx15 eight spoke alloy wheels, similar to what the original MGC GTS

�

racecars used back in the day, except aluminum instead of magnesium. Vent holes in the knock-off

�

nuts help cool the front wheel bearings. At Sebring in 1969, RMO-699F reverted to spoke wheels.

�

In his trailer, Ken carries a set up Borrani 15x8 wire wheels with Hoosier tires as a back-up.

�

�

Hoosier Speedster P205/60R15 racing tires. Ken Williamson reported:

�

"Increasing tire pressures to 30psi (cold) seemed to improve handling a great deal."

�

| Notes: | ||

| (1) | �

Targa Florio officials called time after twenty-two cars crossed the finish line even though�

three other cars were still running. If they had waited a few more minutes, MBL-546E might have�

finished 25th overall and third place in the "P +2000" class, which incidentally was the largest�

displacement "prototype" racing class in the 1967 race. Although race reports show MBL-546E's�

result as "not classified". The race consisted of ten laps of a 72 kilometer circuit.�

MBL-546 completed eight laps before time was called. It was a disappointing result.�

� | |

| (2) | �

When you see coverage of Sebring races from this late sixties, class results can be quite�

confusing due to ambiguity in the ways that cars were subdivided into groups and classes. �

� Period BMC/MG magazine advertisements and countless books for MG enthusiasts have reported� that the MBL-546E won its class at Sebring in 1968. Only four other cars were entered in� Class 11 that year. The #42 Renault Alpine dropped out with timing issues. The� #45 Ferrari 250LM failed to arrive. The #76 Howmet dropped out with broken engine mounts.� Donna Mae Mims' #85 Yenko Stinger (Corvair) was still running at the finish, but was recorded� as "not classified" because she hadn't covered sufficient distance; she was 97 laps behind� the leaders.� � In 1969, the entry list for Class 11 was entirely different. Twelve cars were entered in� the class, and many of them were piloted by world famous drivers. The Ferrari 312P of Chris� Amon and Mario Andretti won first in class and second overall. A Porsche 908/02 piloted by� Rolf Stommelen, Joe Buzzetta and Kurt Ahrens finished second in class and third overall.� Four other Porsche 908/02s were entered. Two finished strongly and two DNF'd. Three fierce� Alfa Romeo T33's were entered, but all three broke. The two MGC GTS racecars did remarkably� well to finish fifth and sixth place in Group 11, well ahead of a Ferrari 250P driven by Pedro� Rodriguez and Chuck Parsons. However, a fifth place finish doesn't make for impressive� newspaper headlines.� � | |

| (3) | �

An MGB GT racecar registered LBL-591E appears frequently with MBL-546E and RMO-699F�

in old photographs. LBL-591E can be differentiated from the MGC GTS racecars by its�

registration number, its MGB style bonnet, its unflared fenders, and its racing�

numbers. At Sebring in 1969, LBL-591E wore racing number 62.�

� � | |

�

| �

�  � Harry Lester's MG P-type (GUR 963), as photographed by Curtis Jacobson for BritishRacecar.com � Did you enjoy this article? We currently have eighty more in process, featuring about 6000 new photos. � But it takes a lot of time and expense to turn photos into articles, and to publish them on the internet. � Please consider making a contribution. Your donation will help us publish more and better articles! � While you're at it, tell us which racecars interest you most. We value the opinions of our funders. � � |

�

Photos shown here are from September 2011 when we viewed the car at The US Vintage Grand Prix at�

Watkins Glen and from November 2011 when we viewed the car at the Vintage Racer Group's annual�

Turkey Bowl at Summit Point West Virginia. Unless captioned otherwise, all photos by Curtis Jacobson�

for BritishRaceCar.com, copyright 2012. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

John Targett 1964 MGB | �

| �

Storm Field 1972 MGB GT V8 | �

| �

Eddie Beal 1978 MGB | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�