�

�

Kyle Kaulback's 1971 Lotus 69 Formula B (Upgraded) Racecar

� � Owner: Kyle Kaulback� City: Bethel Pennsylvania

� Model: 1971 Lotus Type 69

� Engine: Ford Cosworth 1600cc BDA

� Race prepared by: Powerslide Motorports�

�

Lotus Components Ltd. and the Lotus Type 69

��

Lotus Components Ltd. was founded to design, build, and sell racecars. Separating out Lotus�

Components allowed Colin Chapman's core business, Lotus Cars, to focus on passenger car production.�

Simultaneously Chapman's real passion, Team Lotus, could develop and race Formula One cars without�

distraction. In so many ways, Lotus Components seemed like a very good idea. The outfit grew and�

evolved through the sixties, changed its name to Lotus Racing Ltd., and then collapsed in the early�

seventies. This article is about one of Lotus Racing's final products: Kyle Kaulback's Lotus 69.�

�

Lotus evidently liked the name 69 so much that they applied it to three different car�

models. Many sources will tell you that variants of the Type 69 were specifically designed for�

Formula Two, Formula Three, and Formula Ford respectively.¹ Additionally, some of the Formula Three�

Type 69's were set-up for racing in North America's Formula B class. Exactly one Formula Two Type 69�

was bought second hand, heavily modified by its owner, and then entered in two Formula One races.�

Surely the Lotus Type 69 must have been one of the most versatile racecars ever built, right?�

�

Consider this: the Formula Two Type 69 had a semi-monocoque chassis from the�

firewall forward whereas Formula Fords weren't even allowed to have stressed skins! Furthermore,�

Formula Two and Formula Ford Type 69s had entirely different suspensions and brake packages - �

distinct designs with no shared parts. The Formula Two Type 69�

had huge racing slicks on magnesium wheels, whereas the Formula Ford Type 69 raced on skinny�

treaded street tires and steel disc wheels. Perhaps from some angle the bodywork may have looked�

similar, but no part of it was interchangeable. The Formula Two body was wide in the middle�

to house fuel cells, and big wings were attached at both front and rear. Openings for radiators�

were sized differently. And then there was a Formula Three Type 69: somewhere between the two�

extremes and truly its own distinct model too. A potential customer (or modern historian)�

might have great difficulty pinning down an accurate definition of its unique features. We'll try.�

�

How successful were these cars on the racetrack? In his Type 69, Jochen Rindt dominated the first�

Formula Two race of the 1970 season but focused on Formula One through mid-season. (Rindt died�

tragically while testing his Lotus Formula One car for the Italian Grand Prix race in September�

1970.) In 1971, Emerson Fittipaldi drove a Formula Two 69 to five victories. In summary, the�

Formula Two 69 proved very competitive when in the right hands, but never scored enough championship�

points to really shine.�

�

The Formula Three Lotus 69 was introduced a year later, in 1971, and in that year Dave Walker drove his�

Ford Twin Cam powered Formula Three 69 to 25 wins from 32 starts to win two different Formula Three�

championships in one year. (Walker was particularly successful late in the season, after a rule change�

regarding restrictor plates sped up the whole field.) �

�

Evidently sales weren't brisk enough to make the division profitable. Colin Chapman pulled the plug�

on Lotus Racing Ltd. before the end of 1971, and all the Type 69 models were discontinued. (Incidentally,�

many core members of the team who created the Type 69 models moved on to form a new company called�

Group Racing Developments.)�

Team Lotus developed and raced a Type 73 F3 car in 1972 and a Type 74 F2 car in 1973, but their�

hearts weren't really in these class; they were a Formula One team.�

�

The Lotus 69 featured in this article is a unique hybrid between the original Formula Two and�

Formula Three Lotus Type 69 models. This particular specimen combines a Formula Three chassis with�

bodywork repainted accurately in its original livery, but upgraded with an engine that would have�

been suitable for Formula Two racing. In this article we'll focus on our specimen, and thus�

generally on Lotus' Formula Three Type 69. �

�

�

�

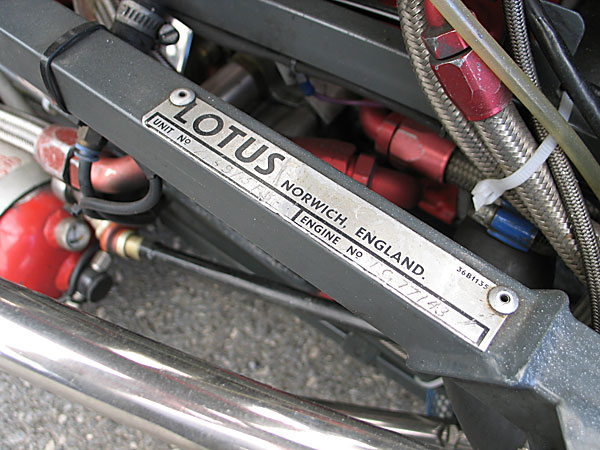

Lotus - Norwich, England

�

Unit No.: 71/69/5FB. Engine No.: TC77143.

�

Kyle Kaulback's Lotus 69 Formula B: 71/69/5FB

��

Kyle's Lotus Type 69 racecar is chassis number 71/69/5FB², which features a Formula Three spec tubular�

steel chassis. In other words, the frame is basically similar to a Formula Ford frame except reinforced�

with lightweight aluminum stressed skins. The "FB" part of its serial number designates that it was�

built up to North American Formula B specifications and delivered complete with a 1600cc Lotus/Ford�

Twin Cam engine. In Formula B, the car would be more powerful than a contemporary Formula Three car�

because it wouldn't be required breath through a single small restrictor plate. In its original�

Formula B configuration Kyle's car would have wings as shown here, but would also have been obliged�

to wear treaded racing tires instead of racing slicks.�

�

The history of Craig's Lotus 69 started auspiciously: Lotus featured it on their stand at the 1971�

Motor Racing Show, in London. After the show, it was shipped to a Canadian driver named Craig Hill.�

Craig was an important figure in Canadian racing for several reasons, not least of them was that he�

was the advertising and promotions manager for Castrol Canada. In that capacity he coordinated�

Castrol's involvement in all forms of motorsport. Craig Hill had also earned special treatment�

from Lotus by winning Canada's Formula B championship in both 1969 and 1970 as a privateer.�

Unfortunately, Formula B fizzled out in Canada just as Hill received his Lotus 69. Hill raced�

the car in an assortment of Formula Atlantic races on both sides of the Canadian / United States�

border, but with limited success.�

�

Craig moved on, and his Lotus 69 FB passed to Ron Shantz and then apparently through a succession�

of North American owners. After some years of club racing, it ended up back in England for chassis�

restoration and installation of a 1600cc Cosworth BDA (i.e. belt drive) engine and Lucas mechanical�

fuel injection. A German enthusiast named Claudia Neuhaus owned and occasionally raced 71-69-5FB�

in the late 1990s. Kyle purchased the car from Ms. Neuhaus and had it shipped back across the�

Atlantic again.�

�

�

�

The ex-Craig Hill Lotus 69 Formula B: restored and wearing its original Castrol GTX livery.

�

�

Kyle's 69 was yellow with a green stripe when he received it and he raced it in those colors�

for several years. He had just returned the car to resplendent Castrol GTX livery shortly�

before we photographed it in May 2010.�

�

Ironically, returning other aspects of the car to original specification would be rather�

expensive and would simultaneously make the car slower. Different vintage racing organizations�

have different rules. As currently configured with its very potent powerplant, Kyle's car is�

eligible to race in Monoposto Racing's "Formula Atlantic" class. This class permits later 1970s era�

open-wheel cars which produce more downforce, so taking a checkered flag is both a huge challenge�

and a great thrill. Kyle's victory in The Jefferson 500 at Summit Point in 2009 was just�

that sort of victory. Kyle explained: "At least I have a good motor. My particular Cosworth BDA�

makes in the range of 250 horsepower... The 69's lack of downforce relative to a March 79 or Ralt�

RT1 is at least an advantage on the straights because the 69 has much less aerodynamic drag."

�

�

�

�

�

�

Features and Specifications

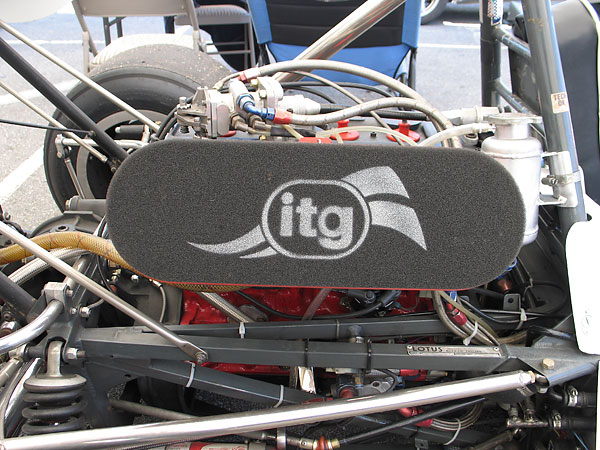

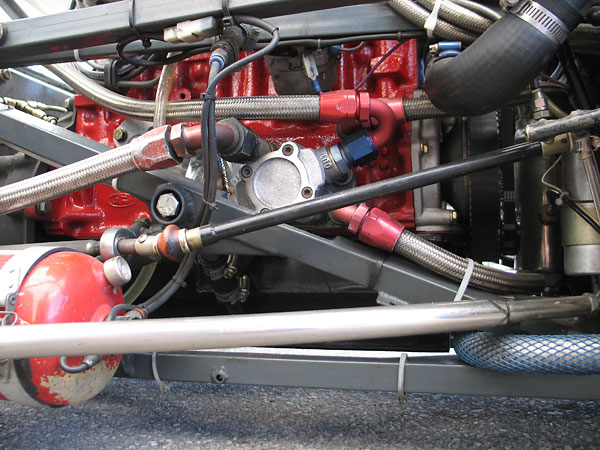

�| Engine: | �Ford / Cosworth 1600cc BDA, rebuilt by Marcovicci-Wenz Engineering.�

Lucas Mk2 mechanical fuel injection.�

ITG foam air cleaner.�

Lucas distributor.�

Lucas ignition coil.�

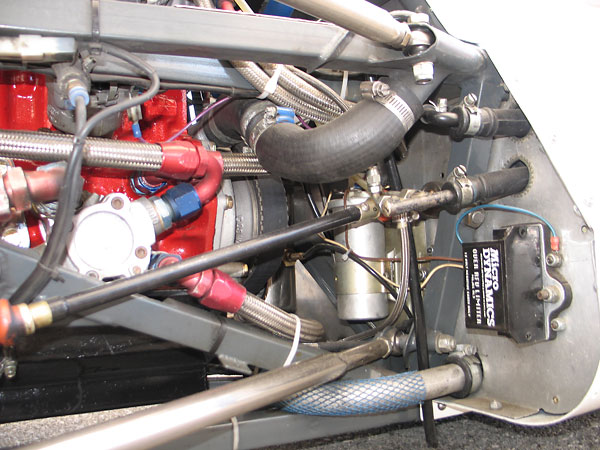

Micro Dynamics electronic rev limiter.�

Magnecor Electrosports 70 (7mm) SS25-200T metallic inductor EMI suppression spark plug wires. | �

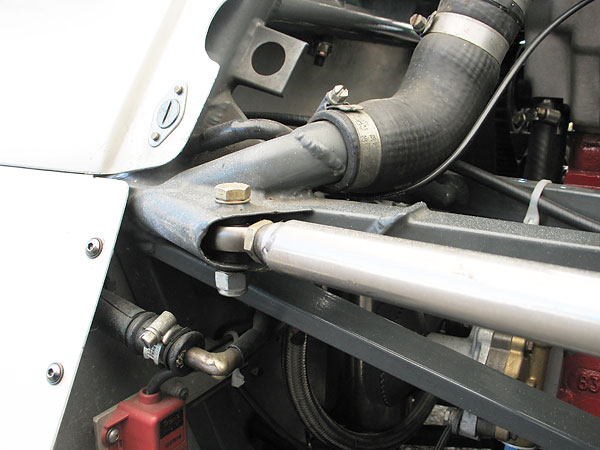

| Cooling: | �custom aluminum crossflow radiator.�

Coolant plumbed through frame tubes. �

Custom fabricated aluminum header tank. | �

| Exhaust: | �custom 4-into-1 header, ceramic coated. | �

| Transaxle: | �Hewland FT200 5-speed.�

Metalastic donuts. | �

| Front Susp.: | �unequal length wide-based wishbones.�

Proprietary Lotus magnesium uprights.�

Koni 3012 double adjustable aluminum bodied coilover shock absorbers, with Eibach springs.�

Adjustable anti-sway bar. | �

| Rear Susp.: | �inverted lower wishbones, single top links, and twin adjustable trailing links.�

Proprietary Lotus magnesium uprights.�

Koni 3012 double adjustable aluminum bodied coilover shock absorbers.�

Adjustable anti-sway bar. | �

| Brakes: | �(master) dual Girling integral-reservoir master cylinders with bias bar. � (front) Girling AR brake calipers and solid rotors. � (rear) Girling NR brake calipers and solid rotors. | �

| Wheels/Tires: | �Lotus magnesium alloy 4-stud racing wheels (13x10 front, 13x14 rear).�

Avon racing slicks (9.0/20.0-13.0 front, 12.0/23.0-13.0 rear). | �

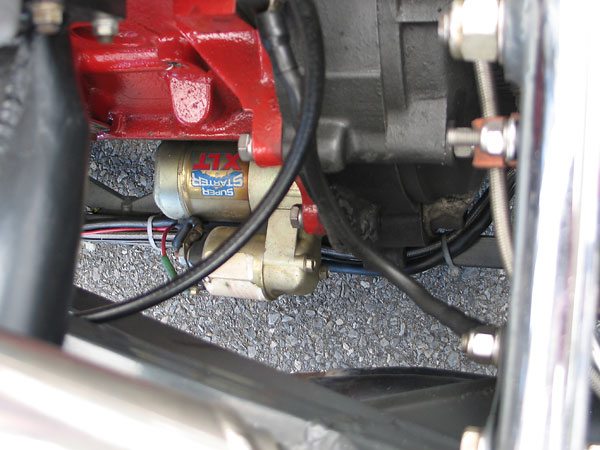

| Electrical: | �Tilton Super Starter XLT gear reduction starter. | �

| Instruments: | �(left to right)�

Racetech coolant temperature gauge (30-110C),�

Smiths Chronometric (a.k.a. cable-driven) tachometer (400-12500rpm),�

Racetech dual oil pressure (0-160psi) and oil temperature (30-120C) gauge, and�

Racetech fuel pressure (0-160psi) gauge. | �

| Fuel System: | �dual side-mounted fuel tanks.�

Electric fuel pump for starting.�

Lucas belt-drive mechanical fuel pump for racing. | �

| Safety Eqmt: | �Schroth six point cam-lock safety harness.�

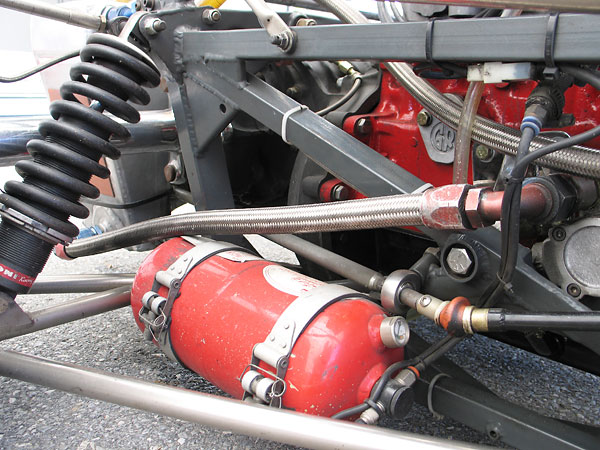

Hybrid Lifeline / S.P.A. (Fire Fighter) electrically actuated centralized fire suppression system. | �

| Weight: | �1040# | �

| Racing Class: | �currently eligible for Monoposto Racing's "Formula Atlantic" class. | �

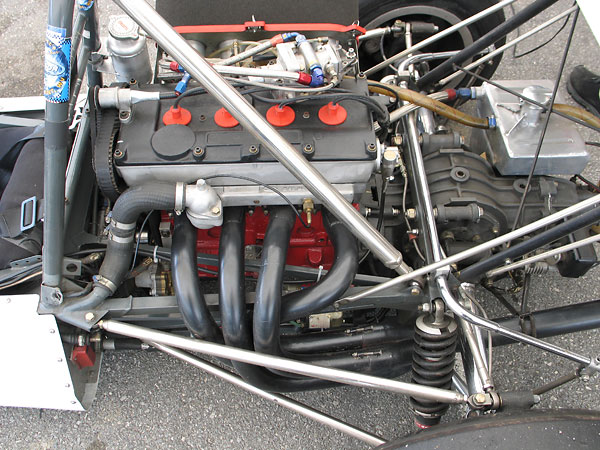

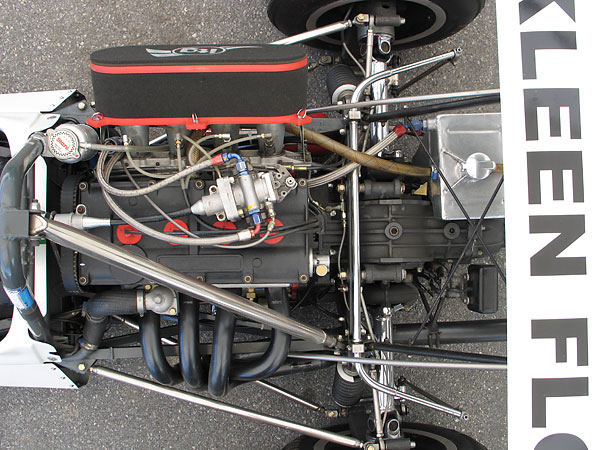

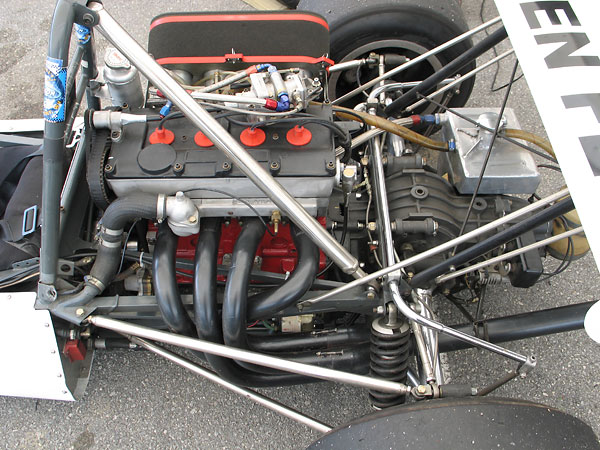

Engine Installation

��

�

1600cc Ford / Cosworth BDA engine, recently rebuilt by Marcovicci-Wenz Engineering.

�

�

Custom 4-into-1 header, ceramic coated.

�

�

The roll hoop is tall, and its offset rear brace provides generous clearance to the engine.

�

�

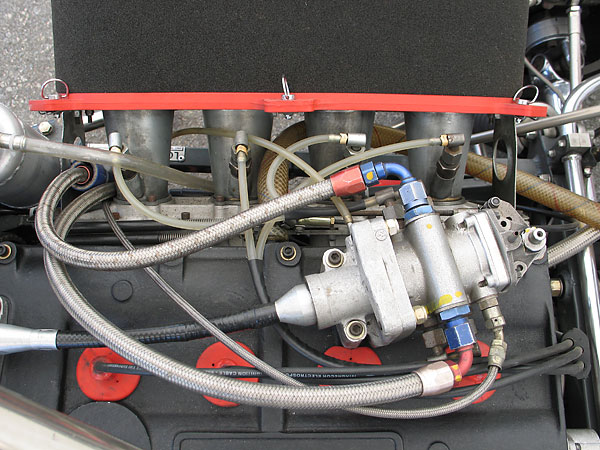

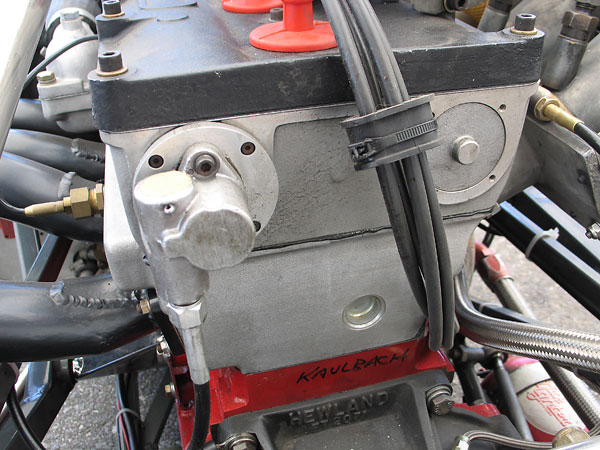

Lucas Mk2 mechanical fuel injection metering valve.

�

�

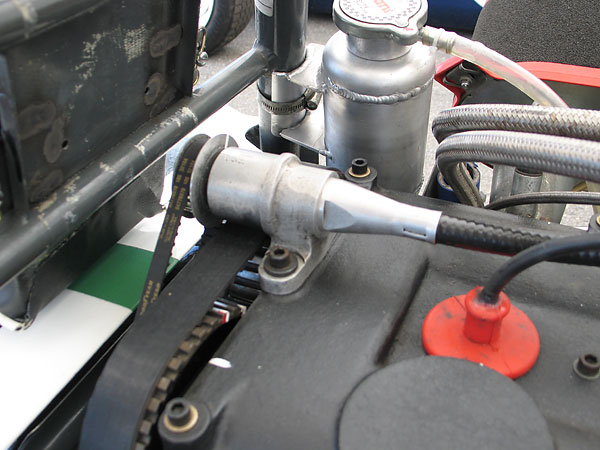

Fuel metering is timed based on a cogged belt driven from the exhaust-side camshaft.

�

Notice the little painted tic marks that simplify alignment upon reassembly

�

�

ITG foam air cleaner.

�

�

Custom fabricated aluminum coolant header tank.

�

�

The name "Cosworth" is cast right into the cogged aluminum pulleys which turn dual overhead

�

camshafts. This part of Cosworth's classic BDA design, where BDA stands for Belt Drive A-Type.

�

Earlier Cosworth dual overhead camshaft engines utilized gear driven camshafts.

�

�

Micro Dynamics electronic rev limiter.

�

�

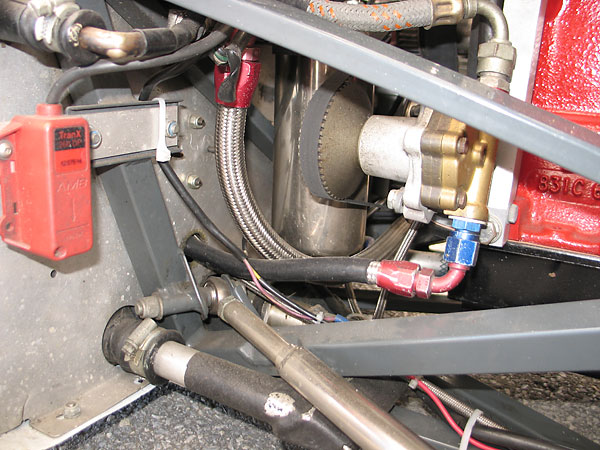

Dry sump lubrication system plumbing, including a special oil pump.

�

�

S.P.A. Fire Fighter fire extinguisher bottle. The fire suppression system can be actuated from a button

�

on the dashboard. It has multiple nozzles, including one located here under the engine's fuel injectors.

�

�

Rear wings are most effective when mounted far rearward, as seen here, because airflow here

�

is less turbulent and because the wings mounts act as lever arms (i.e. they provide "leverage".)

�

�

This elaborate fabricated aluminum engine oil reservoir is a distinctive Type 69 feature.

�

�

This is the drive for a cable-driven fully mechanical chronometric tachometer.

�

�

Tilton Super Starter XLT gear reduction starter.

�

�

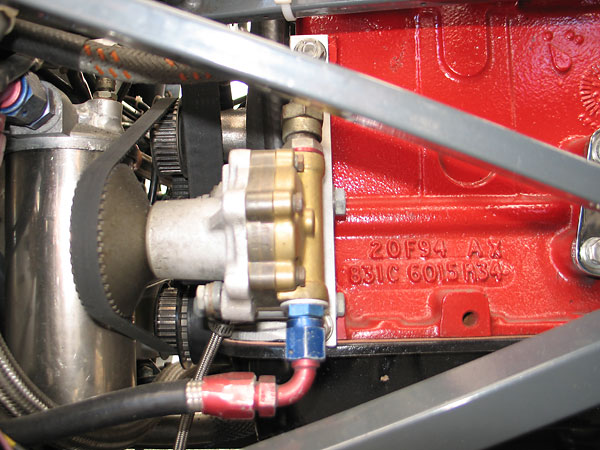

At left: Lucas high pressure mechanical fuel pump. At right: codes on the engine block casting can be

�

interpreted as follows. 20F94 is a date code that indicates this particular engine block was

�

cast on February 20, 1994. AX indicates that this is a South African made engine block. (Ford

�

used these engines in South African built Sierras.) "831c 6015 r34" is basically a part number.

�

Blocks with this part number were originally designed for motorsport and were originally cast

�

in England in the 1980s. These blocks weigh ~10# more than other Ford Kent crossflow blocks.

�

�

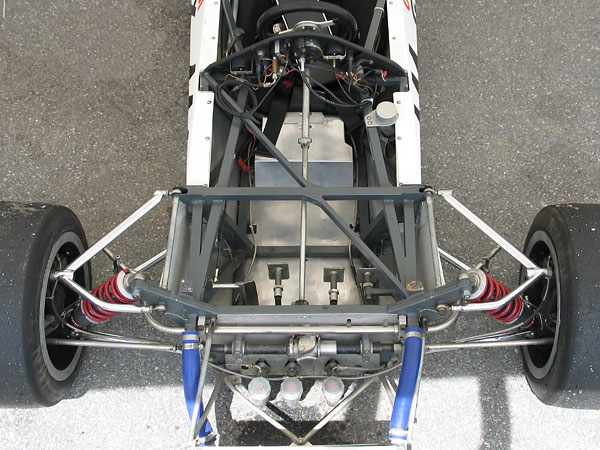

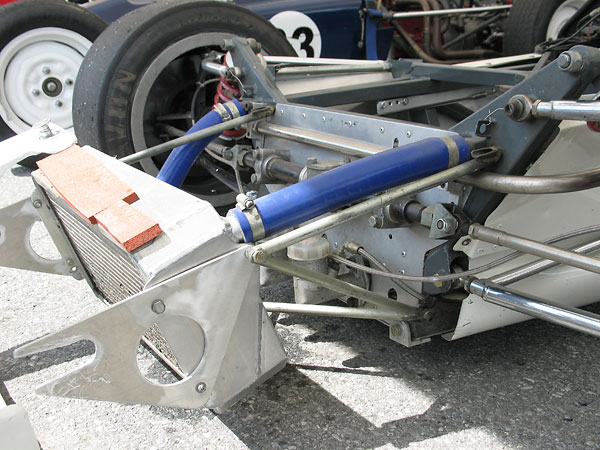

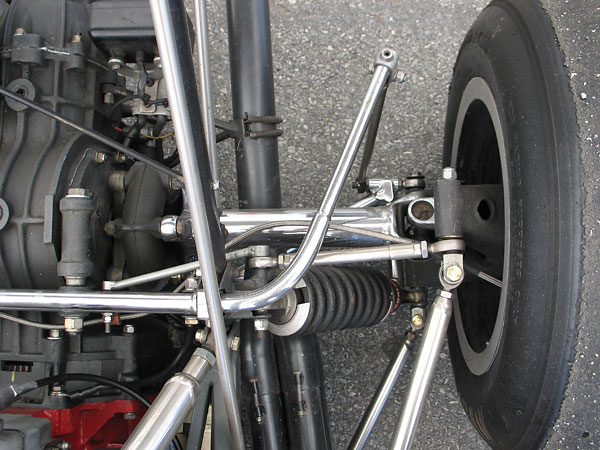

Front Suspension

��

�

Wide tires widely separated.

�

�

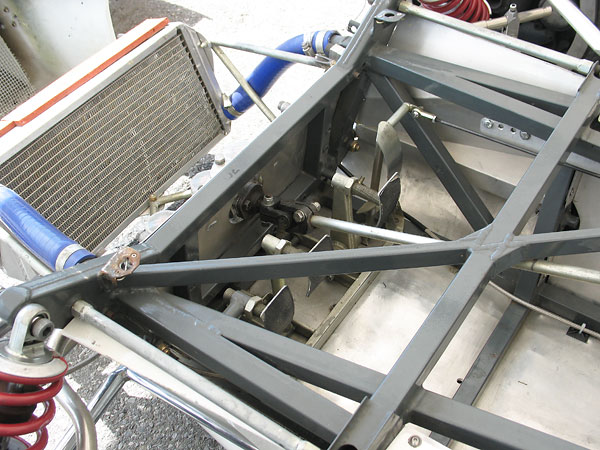

A variety of square and rectangular box tubing sizes were used in Type 69 F3/FF frames. Whereas

�

round section tubing is stronger and more weight efficient for a pure spaceframe, box tubing can

�

be a smart compromise in many situations. For one, it's much easier to attach sheetmetal panels to.

�

�

Now that's a thick radiator core! Note also a sacrificial "skid plate" at the corner of the frame.

�

�

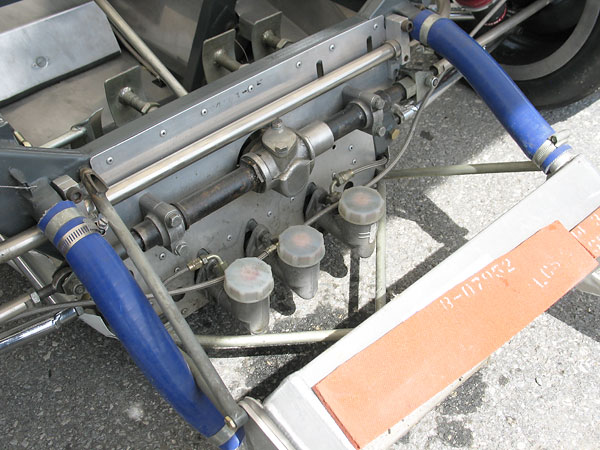

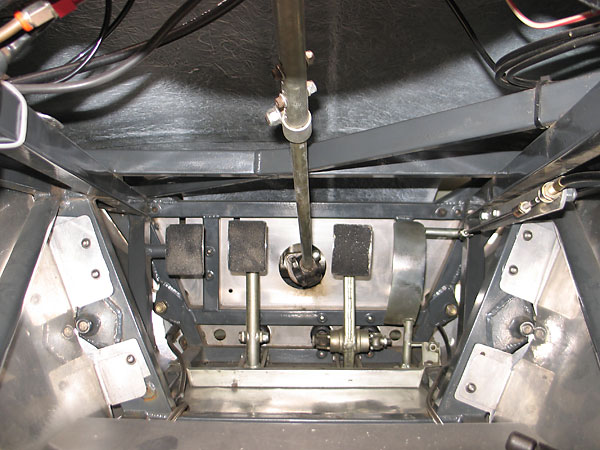

Girling master cylinders.

�

�

Koni 3012 double adjustable aluminum bodied coilover shock absorbers, with Eibach springs.

�

Note: mounting bolts for the upper wishbone screw into opposite ends of a removable bar.

�

�

(These stiffer springs were installed on the car when it arrived at Summit Point.)

�

�

Interestingly, a third member connects the inboard arms of the wishbone yet the

�

anti-sway bar connection is at mid-span and is in single shear.

�

�

Bespoke magnesium uprights. Notice how the steering connection is both strong and easy

�

to adjust up or down as required for tuning out bump steer.

�

�

Why does the anti-sway bar step down in diameter at its ends? Probably it's a lightweight tubular

�

bar with solid sections at both ends to take adjustment clamp pressure without distorting.

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

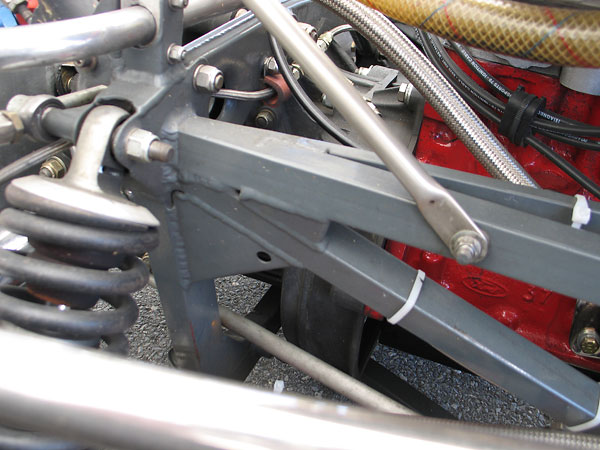

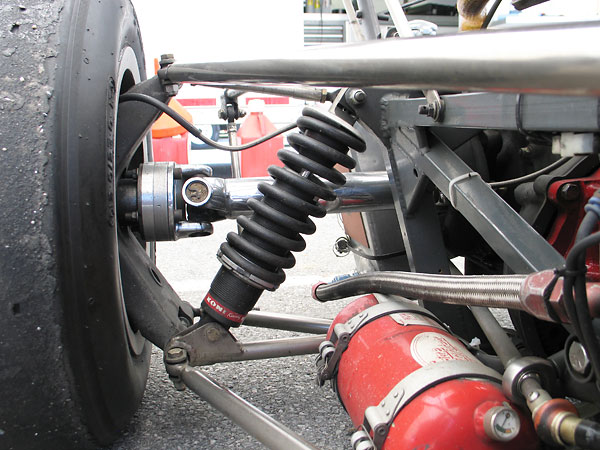

Rear Suspension

��

�

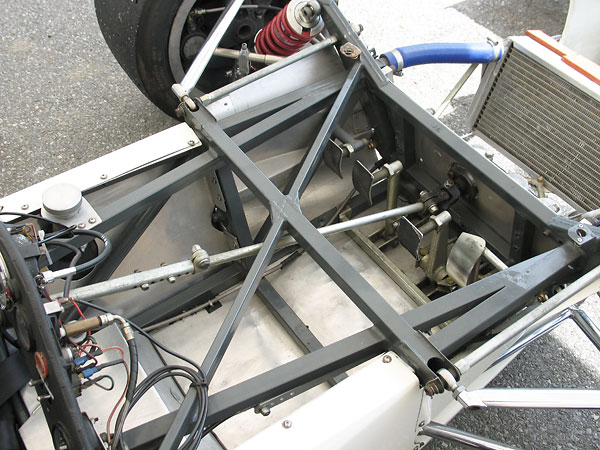

Inverted lower wishbones, single top links, and twin adjustable trailing links.

�

�

Hewland's FT200 transaxle looks so svelte in this view, but inside it's quite robust.

�

Introduced in 1966, FT200 boxes have backed up generations of mid-range formula cars.

�

Nominally rated for 300hp, they can in fact support much more (~500hp!) depending on

�

what ring and pinion ratio is selected and which differential is used.

�

�

The rear anti-sway bar has been adjusted to its absolute softest setting.

�

�

Michael Costin's influence on early Lotus chassis designs is echoed here in the perforated

�

member that reaches across the transaxle. Costin's design approach was very elegant and theoretical,

�

whereas Lotus 69 designer Dave Baldwin's use of gussets and box tubing was all about practicality.

�

�

Koni 3012 double adjustable shocks can be adjusted for rebound on the car by "sweeping" a

�

recessed adjustment pawl at the top eye from side to side. Adjusting compression requires

�

removing the shocks and extending them to their full length, then rotating the shaft.

�

�

Another view of the trailing links...

�

�

To run engine coolant through square section frame tubes, round tube sections needed to be

�

spliced on. Note also the diagonal splice, where fluid is blocked off from rearward flow.

�

�

Someone knew exactly where they wanted this suspension pivot point, and went to a great deal

�

of effort to make it happen. Note also an elaborately fabricated triangular tube evidently

�

equalized fuel level between the dual fuel tanks.

�

�

Metalastik couplings transfer power smoothly and simply.

�

�

The Lotus 69 F3 engine oil reservoir is exceptionally distinctive.

�

�

Interior

��

�

Schroth six point cam-lock safety harness.

�

�

A recessed red button on the dashboard activates the fire suppression system.

�

�

(left to right) Racetech H2O temp gauge, Smiths Chronometric tachometer (400-12500rpm),

�

Racetech dual oil pressure and oil temperature gauge, and Racetech fuel pressure gauge.

�

�

The tell-tale needle on the tachometer indicates that the engine has seen ~9750rpm recently.

�

�

The fuel pressure gauge is marked at 110psi. Cars with mechanical fuel injection generally have

�

two pumps. An electric pump is used for initially starting the engine. An engine driven pump

�

is used during actual racing conditions.

�

�

Two driver-friendly features: a stout dead pedal and a telescoping steering column.

�

�

A high quality feature: finely and relatively easily adjustable pedals.

�

�

Telescoping steering column.

�

�

Exterior

��

�

Kyle Kaulback at Summit Point, contesting the 2010 Jefferson 500.

�

�

Castrol Kleen Flo

�

�

Dave Baldwin gets credit for designing the Type 69 models, and also for designing

�

the Type 59 models from which they were derived.

�

�

How many were produced? The usual estimate is 57 racecars, if you combine all variants.

�

�

This looks Like an original windscreen; shape and tinting match period photos we've studied.

�

�

This appears to be the original roll hoop, but with a larger and more elaborate headrest.

�

Notice that it's removable by turning two Dzus quarter turn fasteners.

�

�

Lotus magnesium alloy racing wheels (13x10 front, 13x14 rear), These are mounted on studs, whereas

�

original F2-spec Type 69s came with knock-on hubs. The code "L122" cast into one of the spokes

�

indicates the specific magnesium alloy used. (L122 is 92% magnesium plus 8% aluminum.)

�

�

Avon racing slicks (9.0/20.0-13.0 front, 12.0/23.0-13.0 rear. ~$950/set)

�

| Notes: | |||||||

| (1) | �

Engine restrictions are one of the main differences between racing classes. �

� F2: from 1967 through 1971, Formula Two cars were permitted to run 1.3 to 1.6 liter engines. By far� the most popular and successful 1.6 liter F2 engine was the Cosworth FVA which featured gear-driven dual� overhead cams and four valves per cylinder, atop a four cylinder Ford Cortina engine block. Generally� featuring Lucas mechanical fuel injection, these engines typically gave at least 220bhp at 9000 rpm.� From 1972, 2.0 liter production-based engines such as the Cosworth BDA (shown above) were allowed.� � F3: Formula Three cars were restricted to one liter displacement engines through 1970. Their highly� tuned and highly strung little engines screamed as they produced about 125bhp. Starting in 1971, F3� teams were allowed to use larger (1.6 liter) engines if 20mm induction restrictor plates were fitted.� The Lotus/Ford Twin Cam seemed like the motor to have. Four throttle bodies would typically draw� air from a common plenum. Air entered the plenum through a single inlet. Clever teams realized this� inlet should be a "converging/diverging nozzle" and that the geometry of its construction was� important. In actual racing conditions, the original 20mm restriction was soon found to be too small.� The newly allowed 1600cc engines were only producing about 110bhp! (The cars were about four seconds� per lap off their previous pace, which wasn't the intent of the rules.) In mid-August of 1971, the� rules were altered and the diameter of the air inlet restriction increased from 20mm to 21.5mm,� where it stayed through 1973.� � FF: by class rules all Formula Fords used essentially stock versions of the 1600cc Ford engine, with� Weber downdraught carburetor, iron crossflow cylinder head, and single camshaft operating valves via� pushrods. In this era, a very well prepared Formula Ford engine would produce 105bhp at ~5900rpm. � � | ||||||

| (2) | �

Chassis number 71-69-5FB shouldn't be confused with chassis number 71-69-5F2,�

which was Emerson Fittipaldi's Cosworth FVA powered, semi-monocoque chassis Formula Two car�

for 1971. Incidentally, Lotus built twelve cars with "71-69-xFB" chassis numbers, versus seven�

cars with "71-69-xF2" chassis numbers. In both cases, "71" in the chassis number designated�

build year 1971. Lotus is generally believed to have also built seven Type 69 Formula Two cars�

in 1970; their chassis numbers followed the pattern "69.F2.x".�

� | ||||||

�

All photos shown here are from April 2010 when we viewed the car at VRG's Jefferson 500�

at Summit Point Motorsports Park, West Virginia. Photos by Curtis Jacobson for BritishRaceCar.com, �

copyright 2011. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Kyle Kaulback 1970 Lotus 61MX | �

| �

Michael Snowdon 1972 GRD 272 | �

| �

Gord Leach 1974 Hawke DL11 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�