�

�

�

Mark Weatherup's 1979 Crosslé 35F Formula Ford Race Car

� � Owner: Mark Weatherup� City: New York, NY

� Model: 1979 Crosslé 35F

� Engine: Ford 1600cc four cylinder

� Race prepared by: Roland Johnson�

�

Crosslé Car Company Ltd.

��

John Crosslé built an 1172cc Ford powered racecar for himself in early 1957�

and raced it through two seasons on the grass motorcycle tracks of Northern Ireland.�

From that humble beginning came a series of progressively more successful 1172cc Ford�

class racecars, Formula Junior racecars, Sports Racing cars, and Formula B racecars.�

By the time the Formula Ford class came into existence, Crosslé Car Company Ltd.�

seemed to be focusing its attention on high-powered classes such as Formula A and�

Formula 5000. �

�

Meanwhile, through 1967 and 1968 the Formula Ford class grew. In 1969, Crosslé�

finally joined the long list of Formula Ford manufacturers with the introduction of�

their 16F model. Forty 16F racecars would be produced between 1969 and 1970, of which�

thirteen went to America. These were fairly successful cars right from the beginning:�

Gerry Birrell used a 16F to win the European Formula Ford championship in 1969.�

Crosslé continued Formula Ford production with the 20F, and then found commercial�

success with the chisel-nosed 30F model of 1975/76 which proved popular with driving�

schools, most notably including the brand new Skip Barber Racing School in U.S.A.�

�

�

�

CROSSLÉ (pronounced "kroz lee")

�

�

Crosslé's single most popular model was the 32F Formula Ford, of which 140�

were built in 1977/78. Of these, 101 were exported, mostly to the United�

States.�

�

The 35F model was Crosslé's update of the 32F for 1979. It was very similar, with the�

most important difference being bodywork changes around the cockpit to make�

the car more comfortable for larger drivers. 58 were built, of�

which 51 were exported. Twenty-two 35Fs went to the Skip Barber Racing School.�

�

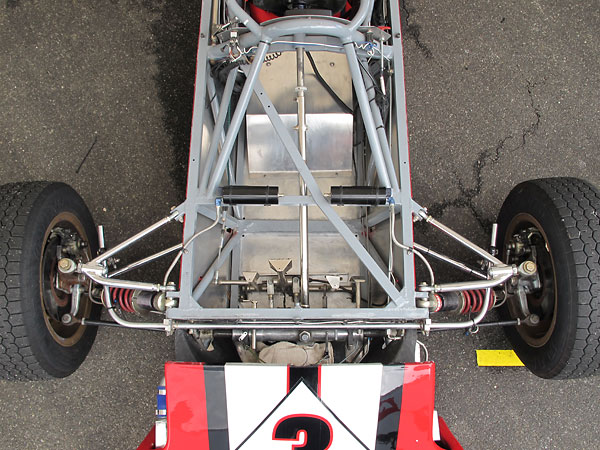

The 32F and 35F share a distinctive wide nose which serves the car well in�

terms of aerodynamic drag and downforce, and improved engine cooling.�

Compared to earlier Formula Fords, the 32F and 35F provided good driver�

protection, particularly in that they included a roll hoop over the�

instrument panel. Out of the box, the chassis isn't especially stiff.�

It lacks any sort of removable brace over or through the engine bay.�

Many owners have strengthened their cars through the middle by adding�

bracing around the cockpit area.�

�

Many successful drivers started their racing careers in Crosslé cars.�

Nigel Mansell owned and raced Crosslé 32F chassis number 37.�

�

Two more iterations of this series of Formula Fords were 1980's 40F�

(30 built, 22 exported) which had a narrower track width for greater�

straight-line speed at some expense of cornering potential, followed by�

1981's 45F (24 built) which returned to the easier-to-drive wide-track�

suspension geometry of the 35F. (There were also Formula Ford 2000�

versions of these car models, called 41F and 46F respectively.) After these,�

Crosslé went to a whole new chassis with inboard-mounted shock�

absorbers and with radiator mounted behind the driver's seat.�

�

�

�

�

�

�

�

Crosslé

�

Holywood, Northern Ireland.

�

Chassis No. 35 F 79 11

�

Features and Specifications

�| Engine: | �Ford Kent 1600cc with aluminum cylinder head, rebuilt by Ivey Engines, Inc. in early 2011.�

Weber 32/36 DGAV carburetor.�

Bosch distributor.�

Pertronix Ignitor breakerless ignition module.�

Bosch blue ignition coil.�

Taylor Spiro-Pro 8mm silicone spark plug wires.�

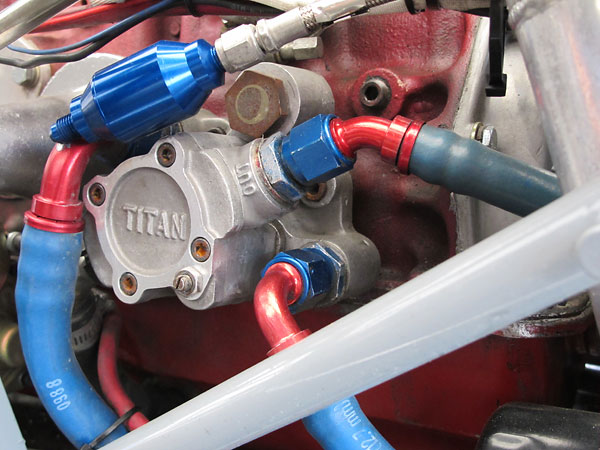

Titan oil pump.�

Dry sump lubrication system. | �

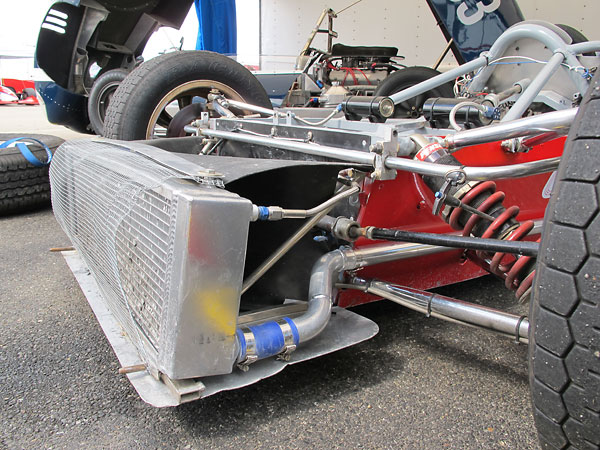

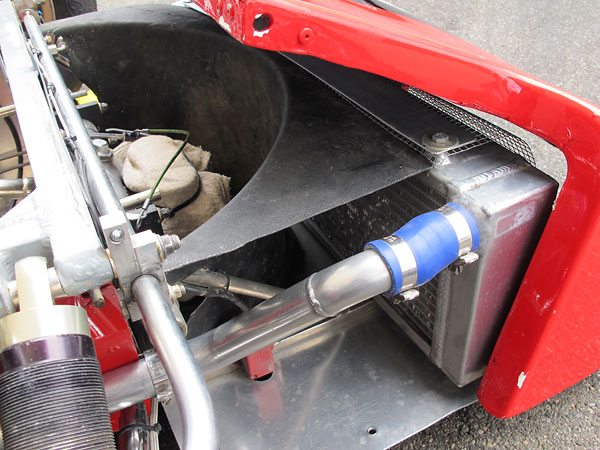

| Cooling: | �Howe aluminum crossflow radiator.�

Bicknell Racing Products aluminum coolant surge tank (model 570).�

�

| �

| Exhaust: | �Hytech Headers stainless steel tri-Y headers featuring patented anti-reversion chambers.�

(A Coast Fabrication lightweight stainless muffler is used as required to meet sound rules.) | �

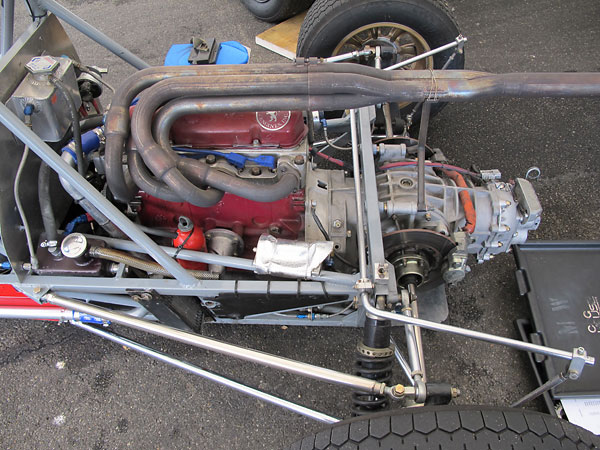

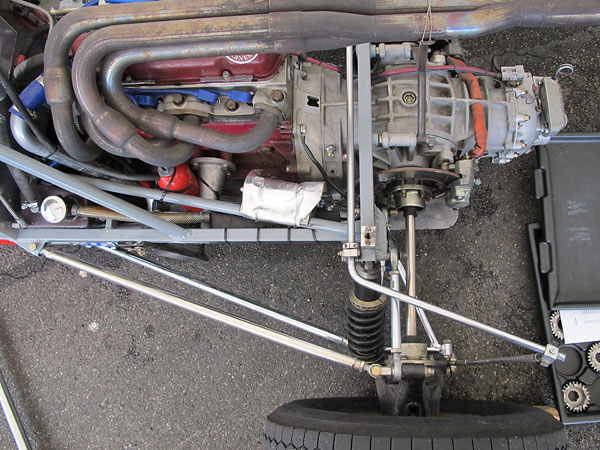

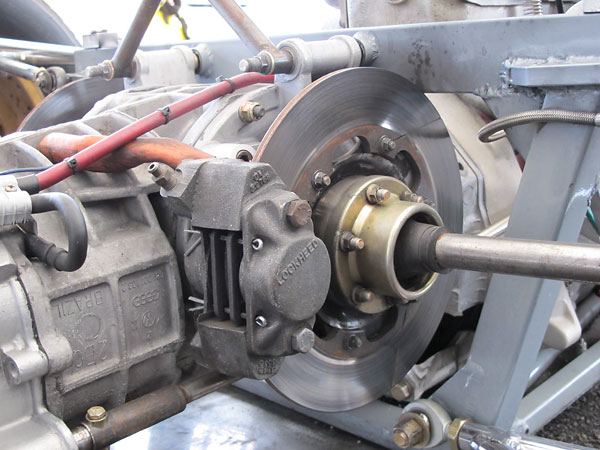

| Transaxle: | �Hewland Mk9 4-speed, with reverse.�

CV-jointed half shafts. | �

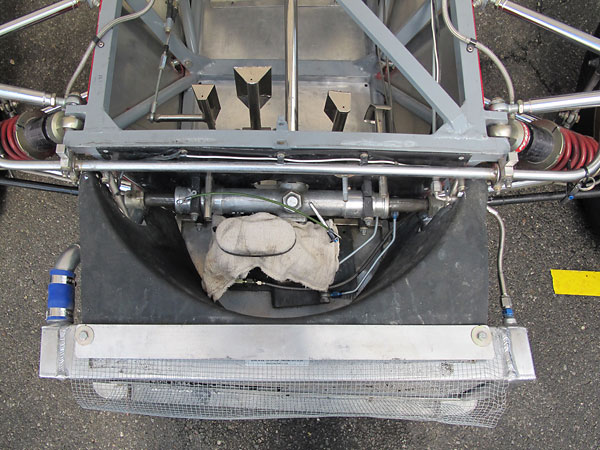

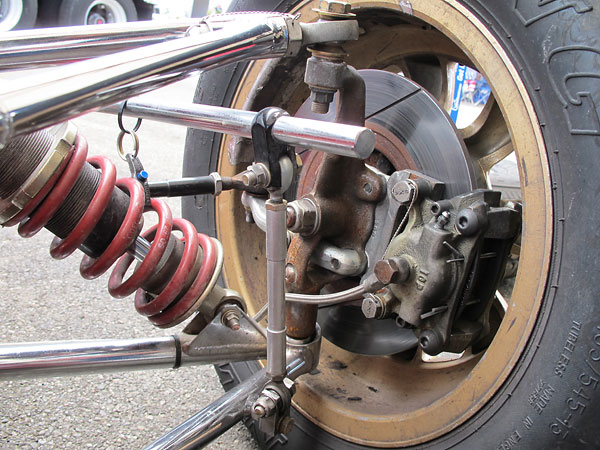

| Front Susp.: | �unequal length wishbones.�

Penske double adjustable coilover shock absorbers, with remote reservoirs.�

Eibach coil springs.�

Adjustable 9/16" anti-sway bar.�

Alford & Alder forged uprights. | �

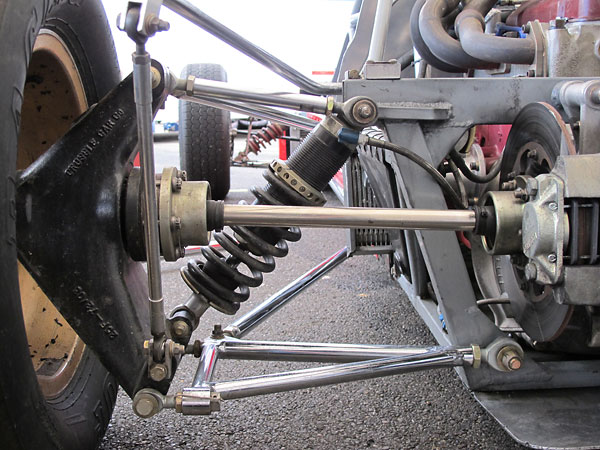

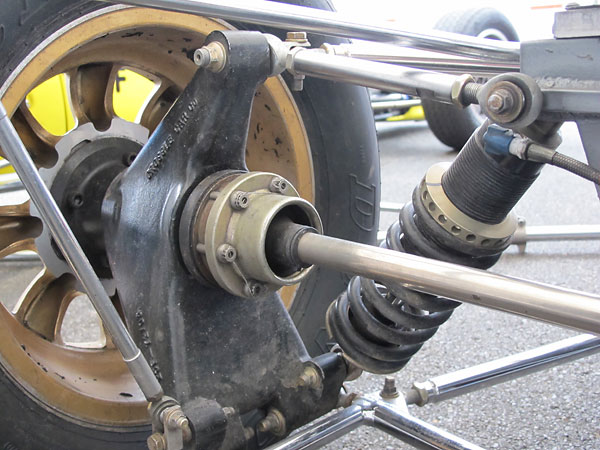

| Rear Susp.: | �inverted lower wishbones, single top links, and twin radius arms.�

Penske double adjustable coilover shock absorbers, with remote reservoirs.�

Eibach coil springs.�

Proprietary Crosslé (25F-72/03) magnesium uprights.�

Adjustable 9/16" anti-sway bar. | �

| Brakes: | �(master) dual Girling master cylinders with remote reservoir and remotely adjustable bias bar. � (front) ICP20 leg-mount calipers. Solid rotors. � (rear) inboard mounted. Lockheed calipers. Solid rotors. | �

| Wheels/Tires: | �Panasport 8-spoke aluminum wheels (13x5.5).�

When photographed in 2010: Dunlop Racing "Formula Ford" tires (135/545-13 CR82 front, 165/580-13 CR82 rear).�

When photographed in 2011: Avon "ACB9" tires (135/545-13 front, 165/580-13 rear). | �

| Electrical: | ��

�

(No charging system.) | �

| Instruments: | �MyChron3 XG LOG multi-function display and data acquisition system.�

| �

| Fuel System: | ��

�

Facet electric fuel pump. | �

| Safety Eqmt: | �Willans six point cam-lock safety harness.�

MOMO suede 250mm flat-bottom, cut-off top steering wheel with�

Racetech quick release steering wheel hub.�

FireBottle centralized fire suppression system. | �

| Racing Class: | �Formula Ford. | �

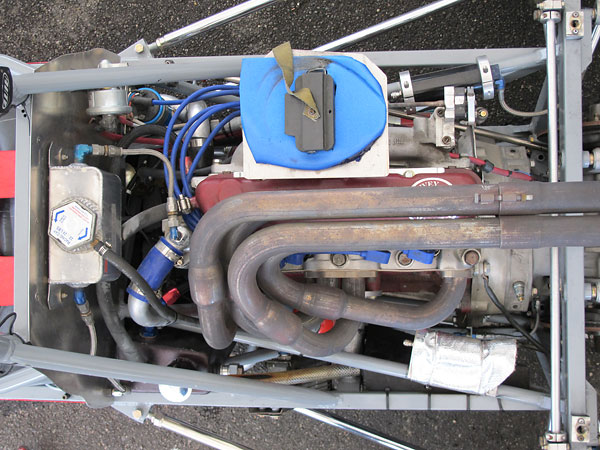

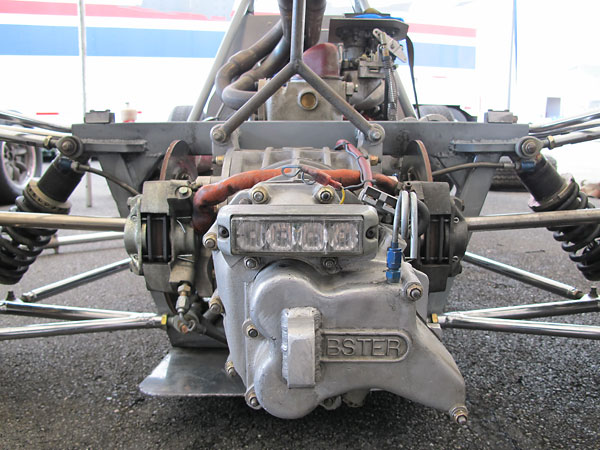

Engine Installation

��

�

Ford Kent 1600cc engine with aluminum cylinder head, rebuilt by Ivey Engines, Inc.

�

�

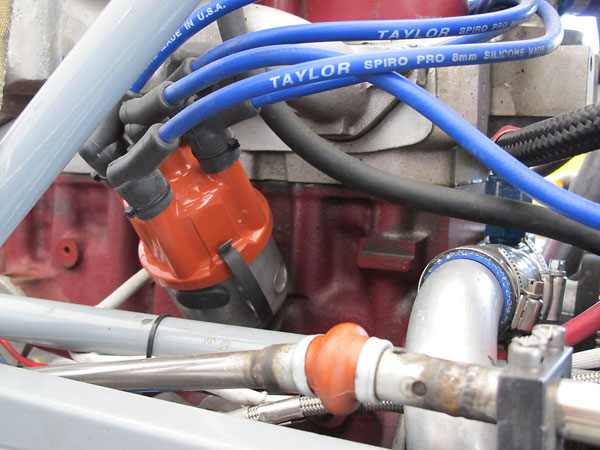

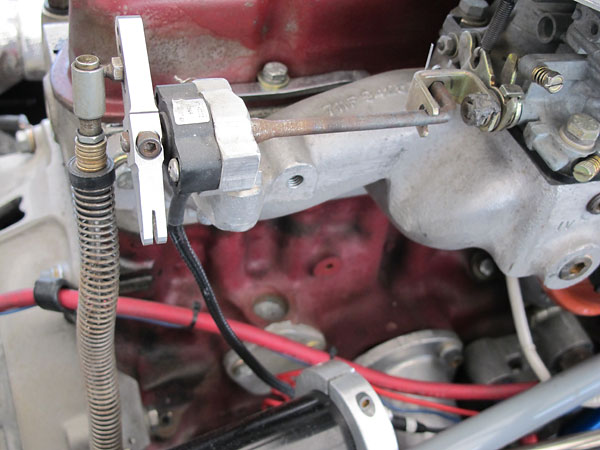

The two leads coming out of this Bosch distributor are your clue that a Pertronix Ignitor

�

breakerless ignition module is installed inside.

�

�

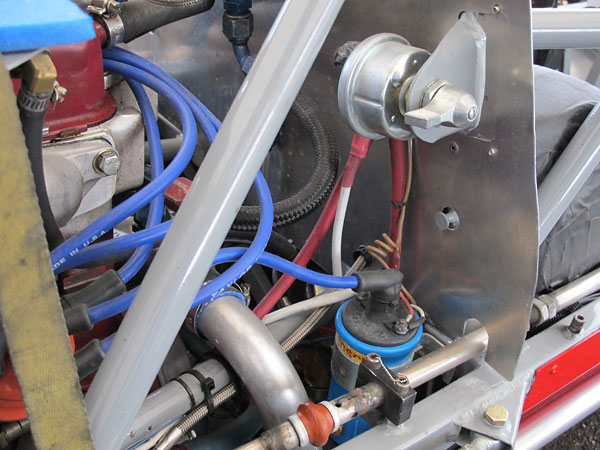

Taylor Spiro-Pro 8mm silicone spark plug wires.

�

(Nylon tie-wraps over cable boots are a nice detail.)

�

�

Bosch blue ignition coil.

�

�

Titan oil pump.

�

�

This throttle position sensor simply provides information to an onboard data acquisition system,

�

which the driver will download to a PC after the race and use to improve his driving strategy.

�

�

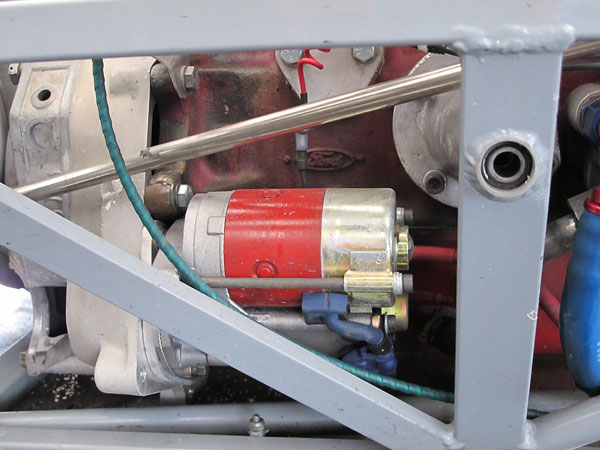

Starter motor.

�

�

Hytech Headers stainless steel tri-Y exhaust header.

�

�

Based on extensive testing, Hytech advocates (non-traditional) sequential cylinder pairing.

�

�

Hytech's patented anti-reversion chambers.

�

�

Where stricter sound control rules apply, Mark uses an unrestrictive

�

ultra-lightweight stainless steel muffler from Coast Fabrication.

�

�

Howe aluminum crossflow radiator.

�

�

After passing through the radiator, airflow exhausts to the sides.

�

�

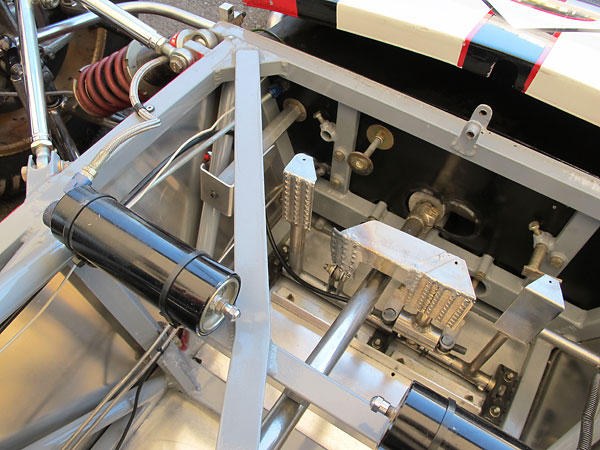

Master cylinders.

�

�

Bicknell Racing Products aluminum coolant surge tank (model 570).

�

�

Aluminum oil cooler.

�

�

Front Suspension

��

�

The Crosslé nose cone serves as a fairing for the car's externally mounted coilover shock absorbers.

�

This design approach would quickly become obsolete. In the early eighties, springs and dampers

�

moved inside the frame, uprights were tucked deeper into wheels, and radiators were relocated to

�

behind drivers' seats. The era of serious Formula Ford streamlining was just about to begin!

�

�

1600cc Formula Ford class rules have always forbid use of wings to produce aerodynamic downforce.

�

Clever designers have nonetheless put a lot of attention, beyond streamlining, into achieving some

�

measure of downforce without accumulating excess drag force. Crosslé 32F and 35F cars are some of

�

the most recognizable in Formula Ford due to their distinctive noses, which illustrates this balance.

�

�

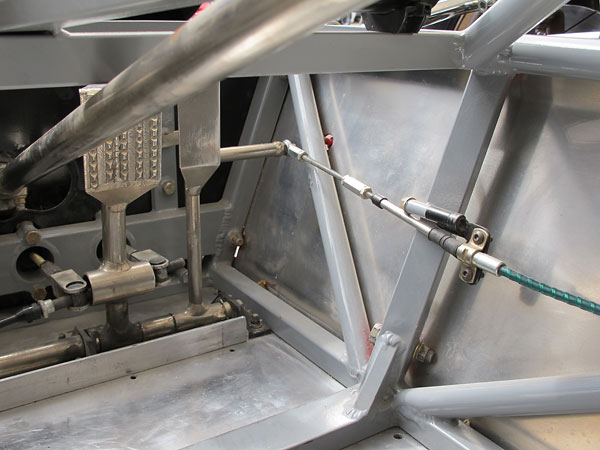

Front suspension pick-up points are strategically placed at nodes in the frames layout.

�

(Note: the diagonal brace above the footbox has been replaced. The original was straight, not bent.)

�

�

An unusual arrangement: outboard shock absorbers are usually oriented perpendicular to a car's

�

longitudinal axis, designers usually prefer as wide a base for suspension wishbones as feasible,

�

and bends along the legs of wishbones are usually avoided. What were they thinking?

�

�

Notice that the Penske shock absorbers are mounted "upside down" in that the shaft end is downward.

�

(These are nitrogen gas-filled shocks, so they can be mounted in any orientation. There's less unsprung

�

weight when mounted this way.) Rebound adjustment is made at the bottom end of the shaft by inserting

�

a thin screwdriver into the small opening and "sweeping" an internal shaft clockwise or counterclockwise.

�

�

Penske 8100 Series remote shock absorber reservoirs. A piston within each reservoir separates the

�

oil-filled (dial) end from a charge of nitrogen gas. Compression adjustment is made via a dial on the

�

remote reservoir which selects one of six orifice sizes. ("One" is largest and thus softest.) Gas pressure

�

is typically about 175psi, but altering the gas pressure provides additional adjustment.

�

�

ICP20 leg-mount iron brake calipers squeeze iron solid brake rotors.

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

Rear Suspension

��

�

For racing on a damp track the rear anti-sway bar has been adjusted to its softest setting.

�

�

Beginning in the 70s, constant velocity joints became commonplace and cost effective with increased

�

popularity of front wheel drive economy cars. By 1979, Crosslé was installing CV joints on new

�

Formula Ford racecars. Despite a premium initial cost, these parts are reckoned maintenance free

�

for the life of the racecar (unless contaminated by grit.) Earlier vintage Formula Fords are required

�

by class rules to instead use Metalastik rubber drive "doughnuts".

�

�

Proprietary Crosslé (25F-72/03) magnesium uprights.

�

�

Long upper and lower trailing links were a ubiquitous feature of British open-wheel racecars

�

since about 1960. In the early eighties this began changing. Crosslé traded-in upper links

�

for a rocking lever arm design in 1985 on their 60F model. Lower trailing links stayed much later.

�

�

Penske Racing Shocks (PRS) shock absorbers with remote reservoirs.

�

�

Inboard mounted rear brakes, featuring lightweight Lockheed calipers.

�

�

Webster Gears is an American company that has produced replacement parts for Hewland

�

transaxles since 1976. They've also produced complete custom gearboxes.

�

�

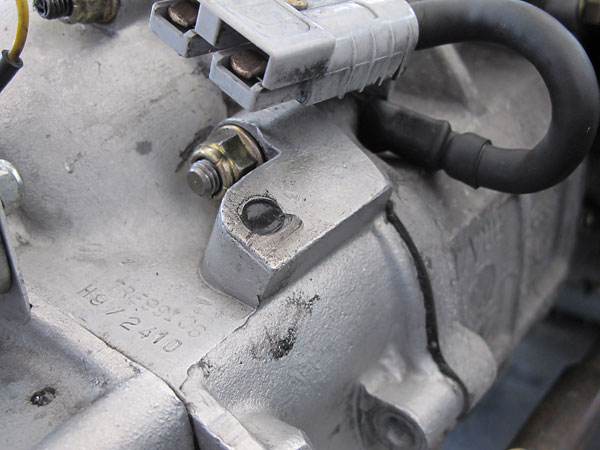

Taylor Race Engineering: 99106

�

Hewland: H9/2410

�

�

Until a racecar is driven at speed on a particular racetrack, it's very difficult to anticipate what

�

combination of gear ratios will suit best. Hewland transaxles makes gear swaps easy.

�

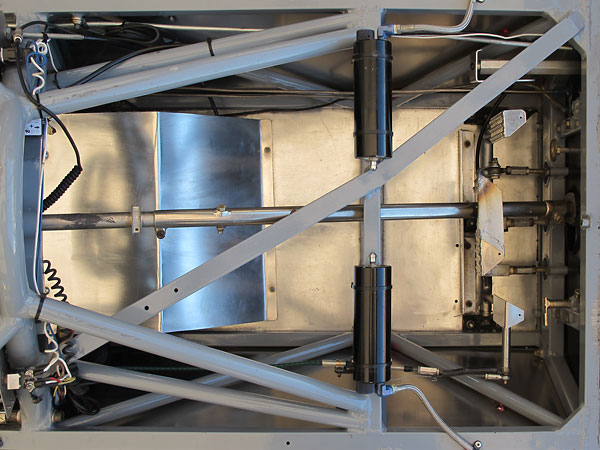

Frame Reinforcement

��

�

Substantial modifications have been made to this Crosslé 35F's frame. The forward roll hoop has

�

been replaced with one of similar height, but with braces attached on either side, instead of at the top.

�

�

More importantly, two long curved tubes have been added around the cockpit opening.

�

This popular modification improves the frame's rigidity and its crashworthiness.

�

�

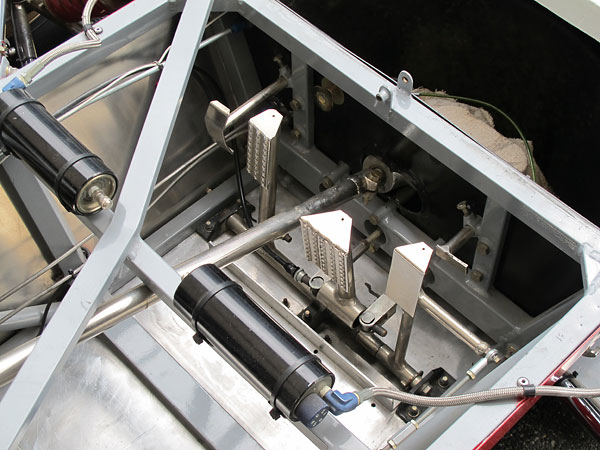

Interior

��

�

MOMO suede 250mm flat-bottom, cut-off top steering wheel.

�

�

Racetech quick release steering wheel hub.

�

�

The MyChron3 XG LOG is more than digital instrumentation; it's the hub of a sophisticated data

�

acquisition system with five fully configurable input channels plus a built-in lateral G-sensor. The

�

data logger features a 200Hz sampling and recording rate, and stores data in an 8MB buffer. The

�

user can connect sensors for temperature readings, fluid pressure readings, potentiometers (e.g.

�

suspension travel, pedal displacement, steering angle, roll angle, etc.), Lambda air/fuel ratio values,

�

etc. The G-sensor helps users correlate other data to track position. Using powerful included

�

software, the system automatically creates a virtual map after data is downloaded to an offboard

�

personal computer.

�

�

Willans six point cam-lock safety harness.

�

�

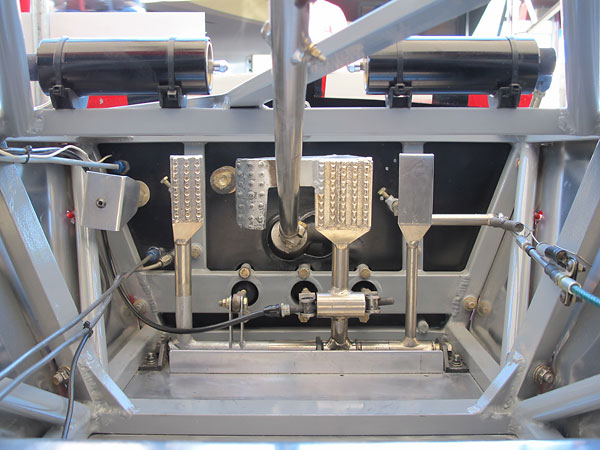

All the pedals pivot on a common bar, and the driver's heels rest against a common stop.

�

�

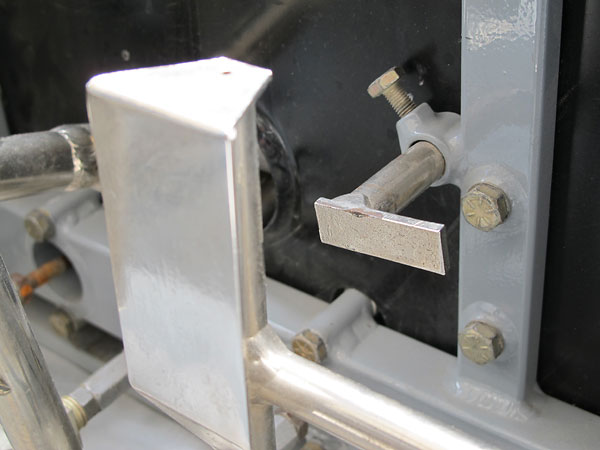

A pedal stop on the throttle pedal. This can be carefully adjusted so that the throttle opens fully

�

yet never goes over center. Installed at this end of the cable, not at the carburetor, the

�

throttle cable won't be stretched if the driver puts his weight on the pedal.

�

�

Throttle pedal/cable connection.

�

�

Between our two photography sessions, Mark has had one aspect of the chassis updated: it's now set-up

�

for left foot braking. The clutch and brake pedals have both been modified. Now the brake pedal can be

�

reached by the driver's left foot without him having to move his foot across underneath the steering column.

�

�

A new dead pedal for bracing the left foot has been added, although only needed when right foot braking.

�

The revised clutch pedal is no longer aligned with its old positive stop. The usual reason for having such a

�

stop in the first place is to protect the clutch slave cylinder from seal damage due to hyperextension.

�

(Depending on the mechanics of the system, a positive stop may be unnecessary.)

�

�

A simple aluminum panel hides and protects the battery and the fire suppression system bottle.

�

�

Comfy, custom-molded two piece foam backrest.

�

�

A Chase Cam PDR100 digital recorder has been mounted above the fuel cell, and discretely

�

behind the driver's backrest This device stores camera data, for playback after the race(s).

�

�

Exterior

��

�

Roland Johnson prepares Mark Weatherup and his Formula Ford for each race.

�

�

A similar nose - except much wider - was used on Crosslé's 33F Formula Ford 2000 model.

�

�

Formula Ford / The Series

�

�

Design by CHICANE - Kati Krueger - (917) 751-2195

�

Norm's Auto Body - www.normsautobody.com - (818) 882-2565

�

�

Ivey Engines, Inc.

�

�

This extended engine cover isn't really a wing... but it may produce a little downforce.

�

�

Normally the exhaust on a Crosslé 35F comes through the bodywork on the lefthand side,

�

but this modification - with exhaust coming straight out the back - sure looks nice!

�

�

Unless otherwise noted, all photos shown here are from September 2010 when we viewed the car at�

The US Vintage Grand Prix at Watkins Glen. All photos by Curtis Jacobson for BritishRaceCar.com,�

copyright 2011. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Kyle Kaulback 1971 Lotus 69 | �

| �

Scott Fairchild 1972 Royale RP3A | �

| �

Gord Leach 1974 Hawke DL11 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�