�

�

Andy Antipas' 1973 Titan Mk6 Formula Ford Racecar

� ��

Owner: Andy Antipas

�

City: Littleton, Colorado

�

Model: 1973 Titan MkVI

�

Engine: Ford Kent 1.6L

�

Prepared by: owner�

�

Titan Formula Fords

��

Charles Lucas Engineering introduced their Titan Mk6 model in 1970. It was the company's third�

offering for the popular Formula Ford class. It would become one of the best selling Formula Fords�

in history. �

�

What came before it? The Titan Mk1 and Mk2 models were one-off racecar projects, never intended for�

serial production.¹ In 1967, Charles Lucas selected the name "Titan Mk3" for his company's first�

product introduction. The Titan Mk3 model was specifically�

designed for Formula Three.�

�

Four for Ford: the Titan Mk4 model was essentially a de-rated and cost-reduced version of the Mk3�

with a nominally stock Ford Cortina engine in lieu of the Mk3's well developed, Lucas-tuned,�

Ford/Cosworth MAE racing engine. Produced through 1968, the Mk4 was engineered to meet all the rules�

which made Formula Ford an inexpensive place for young drivers to get started in roadracing. �

�

The most significant technical difference between Titan's Mk4 and the Mk5 for 1969 was that�

Titan Mk5 racecars were supplied with newly available Hewland Mk8 gearboxes.�

�

Design changes for the 1970 season were more clearly visible. Designer Roy Thomas provided the new�

Mk6 model with Brabham BT23 style, wide based, two piece upper control arms. This provided racers with�

noticeably surer feel and grip, especially under heavy braking loads. Furthermore, Thomas redesigned�

the bodywork to improve downforce and reduce drag. �

�

�

�

�

�

�

The Titan Mk6 quickly earned a great reputation by winning important races. In the U.K., Derek Lawrence�

and Ken Bailey won at least 35 major races. Lawrence placed second in the 1972 BOC Championship, third in�

the 1972 Sunbeam Electric Championship, second in the Daily Express Championship, and second in�

Britain's important 1972 Formula Ford Festival. He also won the 1973 STP Championship. Bailey placed�

second in the 1972 Sunbeam Electric Championship. In U.S.A., Jim Harrell drove a Titan Mk6 to victory�

in SCCA's 1971 Formula Ford National Championship. �

�

Race results led to sales. According to the Titan Registry, over three hundred Mk6s were built�

between late 1969 and early 1974. �

�

Despite increasing commercial success, in 1971 company founder Charles Lucas decided he wanted to�

move on to other pursuits. He sold the company to Roy Thomas and his wife Diane. Under Thomas�

family management, Charles Lucas Engineering was quickly reformed as Titan Cars. Production moved�

from Huntingdon where they had been directly opposite the Lola works to a smaller�

facility in nearby St. Neots, about ten miles to the south. The new location was still convenient�

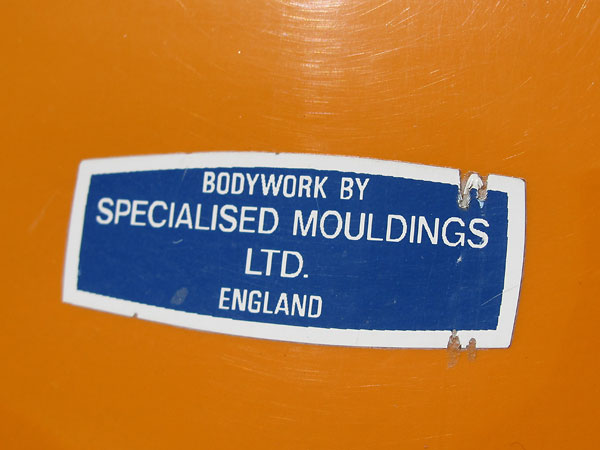

to their two key suppliers: Arch Motors (frames) and Specialised Mouldings Ltd. (fiberglass bodies).�

�

Importers Fred Opert Racing in New Jersey and Pierre Phillips Racing in Oregon were key�

to the success of the Titan Mk6 in North America. Both importers fielded race teams. Interestingly,�

they also created model variants out of thin air so they could market cars as "new and improved".�

Over three and a half years of production, the Titan Mk6 design barely changed. The most notable�

running change was introduction of a revised nose cone (a.k.a. the "duckbill nose") which appeared�

on U.S. market cars during 1973.�

�

�

�

Charles Lucas Engineering and Titan Cars both used this distinctive gryphon logo.

�

A gryphon had previously appeared on the Lucas family's coat of arms.

�

Features and Specifications (as photographed)

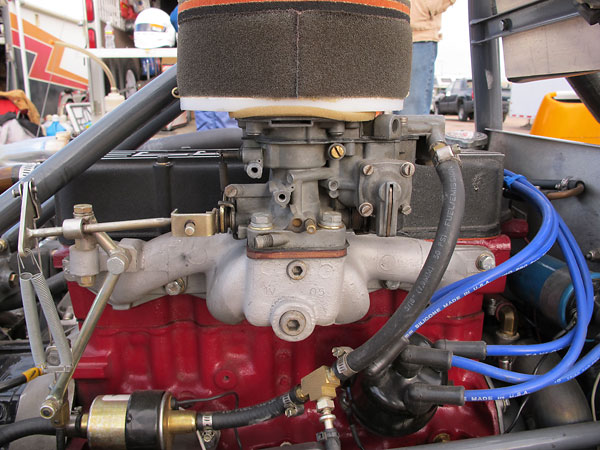

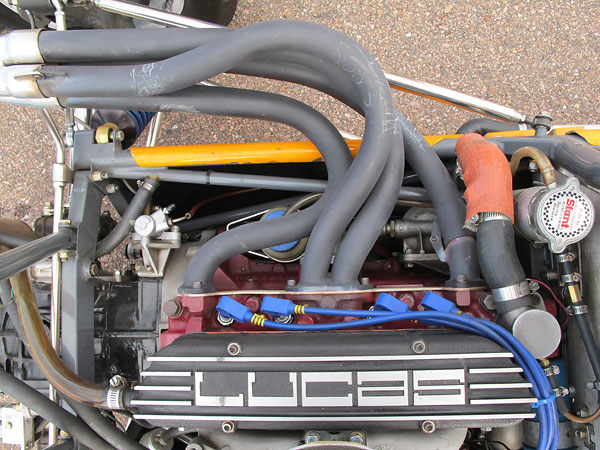

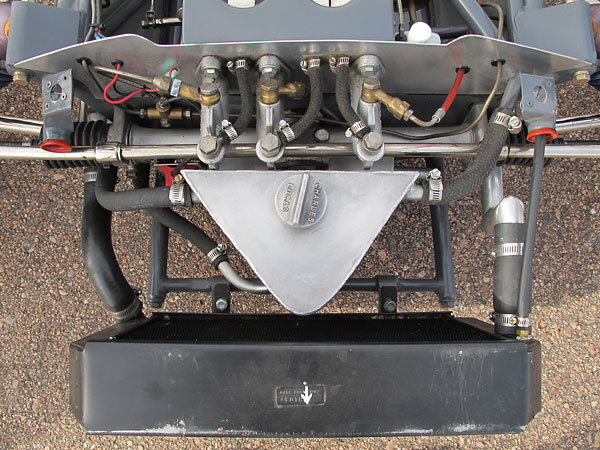

�| Engine: | �Ford Kent 1600cc prepared by Ivey Engines Inc.�

711M6015BA engine block.�

Lucas aluminum valve cover.�

Weber 32/36 DGAV carburetor.�

Pipercross foam air cleaner.�

Motorcraft distributor.�

Bosch blue ignition coil.�

Taylor Spiro-Pro 8mm silicone spark plug wires.�

Dry sump lubrication system.�

Titan oil pump.�

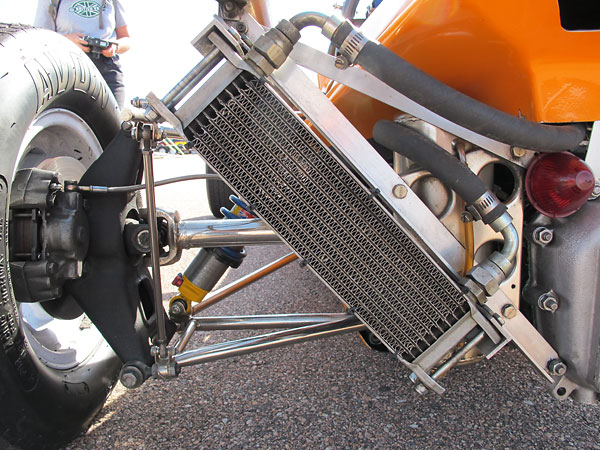

Mocal 10-row aluminum oil cooler.�

Purolator oil filter mount. | �

| Cooling: | �custom copper and brass crossflow radiator from Englewood Auto. | �

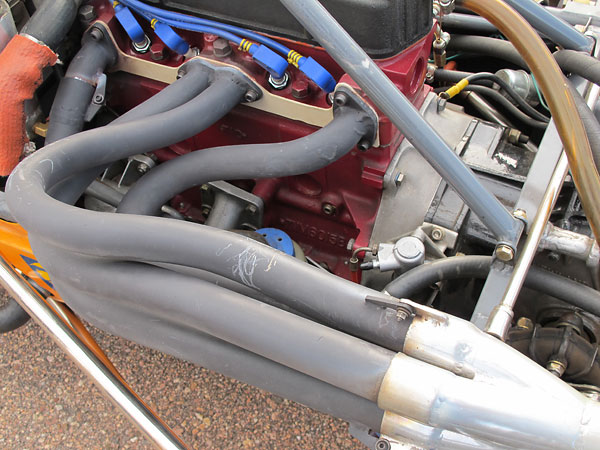

| Exhaust: | �authentic sand-bent four-into-one headers by Mike the Pipe. | �

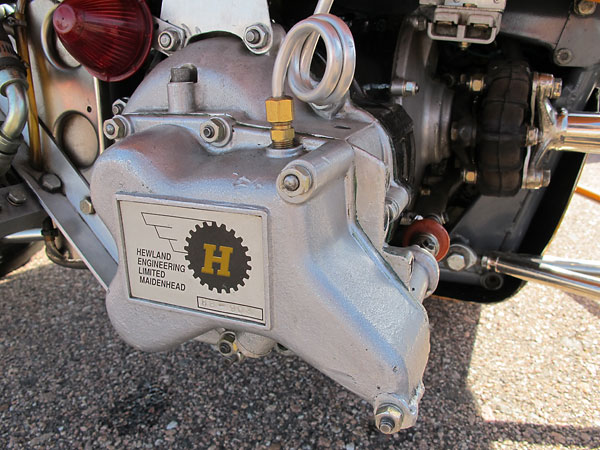

| Transaxle: | �Hewland Mk8 four speed.�

Rotoflex drive couplings.�

Girling 3/4" master cylinder.�

Girling slave cylinder. | �

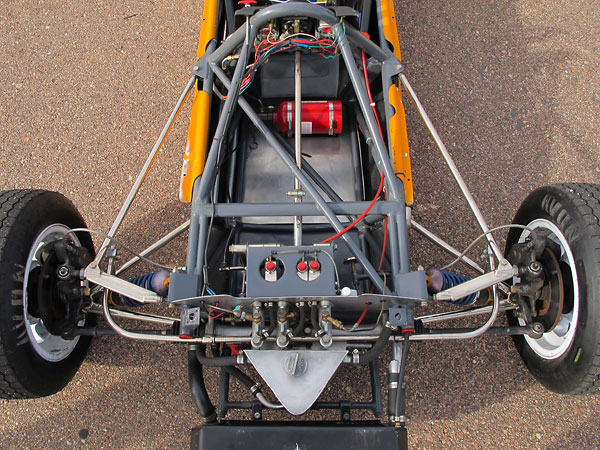

| Front Susp.: | �unequal length wishbones, where the upper wishbone features a two-piece, wide-angle design.�

Alford & Alder (Triumph Spitfire pattern) forged uprights.�

SPAX double-adjustable coilover shock absorbers.�

Adjustable anti-sway bar.�

Titan proprietary steering rack. | �

| Rear Susp.: | �inverted lower wishbones, single top links, and twin radius arms.�

Titan proprietary magnesium uprights.�

SPAX double-adjustable coilover shock absorbers.�

Adjustable anti-sway bar. | �

| Brakes: | �(master) Girling master cylinders (0.7" front, 0.75" rear) with remote reservoirs and remotely adjustable bias bar. � (front) Girling 14LF calipers. Solid rotors. � (rear) Girling 14LF calipers. Solid rotors. | �

| Wheels/Tires: | �American Racing "Silverstone" 8-spoke alloy wheels.�

Avon Formula Ford / ACB9 racing tires (5.0/22.0/13 front, 6.5/23.0/13 rear). | �

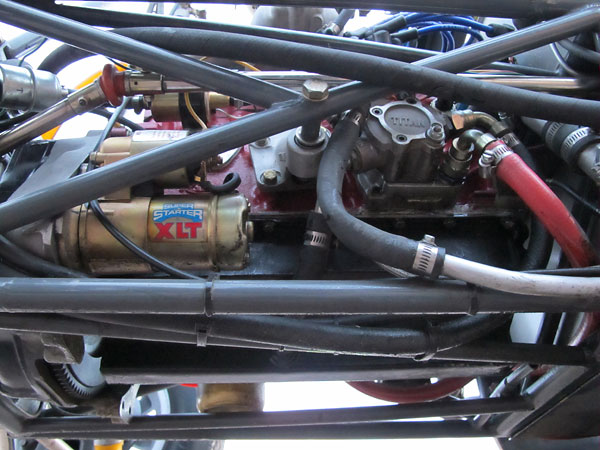

| Electrical: | �Odyssey PC545 sealed/nonspillable drycell battery.�

Tilton Super Starter XLT starter. | �

| Instruments: | �(left to right)�

Stewart Warner coolant temperature gauge (100-240F),�

Smiths Chronometric tachometer (500-8000rpm), and�

Stewart Warner oil pressure gauge (5-100psi). | �

| Fuel System: | �custom Fuel Saft wedge-shaped under-seat fuel cell.�

Bosch electric fuel pump. | �

| Safety Eqmt: | �Sabelt six point cam-lock safety harness.�

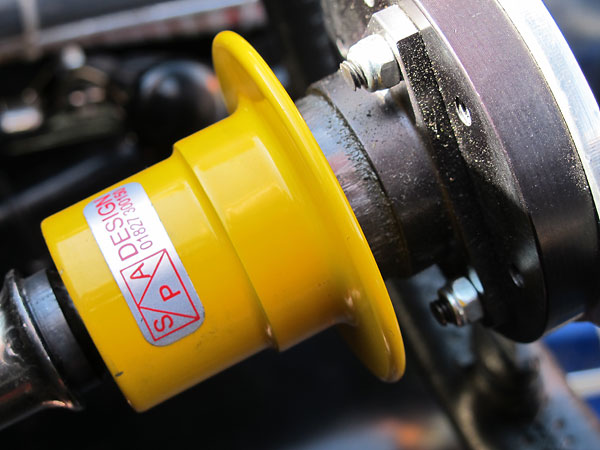

SPA Design quick release steering wheel hub.�

FireBottle Halon centralized fire supression system. | �

Engine Installation

��

�

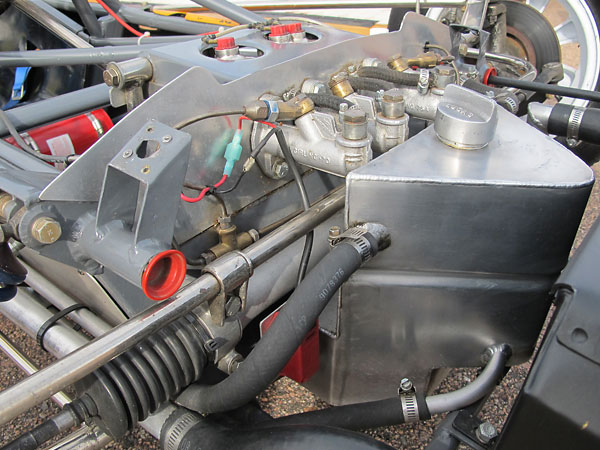

Ford Kent 1600cc prepared by Ivey Engines Inc.

�

�

Weber 32/36 DGAV carburetor.

�

�

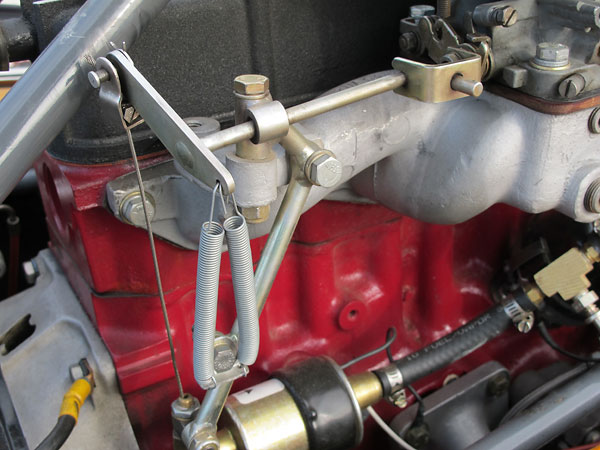

Throttle linkage.

�

�

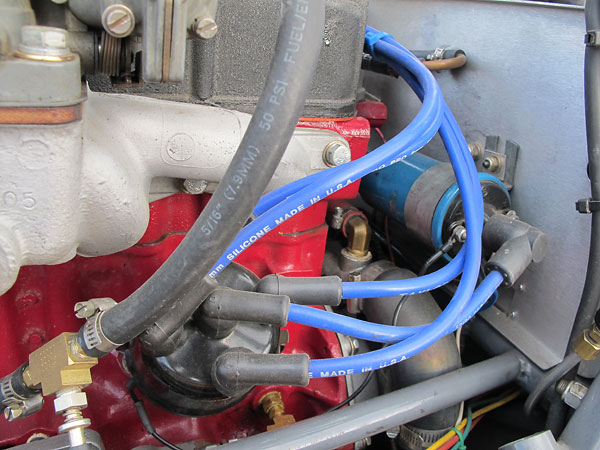

Bosch electric fuel pump, as supplied and recommended by Jay Ivey.

�

�

Bosch blue ignition coil. Taylor Spiro-Pro 8mm silicone spark plug wires.

�

�

Tilton Super Starter XLT starter. Titan oil pump.

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

�

�

Original sand-bent mild steel exhaust headers by famous fabricator Mike the Pipe.

�

�

This is one of the very few vintage racecars we've found with authentic sand bent headers.

�

Advantages: bend radii not restricted to just one or two mandrel sizes, coumpound curves are

�

feasible, there are no seams or ridges at splices to disturb airflow, no expensive bender or

�

dies are required for their fabrication, and - importantly - sand bent headers are period correct.

�

�

Sand bending is a simple process. Workable lengths of mild steel tube are packed with fine-grade

�

dry sand and then capped. (A vent hole is left so hot steam can escape.) An oxy-acetylene torch

�

is used to heat and to keep the tube dark cherry red through the bend area, as a second person

�

carefully draws the tube around a suitable old piece of pipe. It takes skill and practice to

�

get the heat and force distributions right. As shown here, the results are worth the effort.

�

�

An extra slip joint may make header installation and removal easier. It will also help prevent cracking

�

at the connection between tube and flange. As you can see, the flange connections have been

�

brazed (instead of fusion welded) with a large, smooth radius for the same reason.

�

�

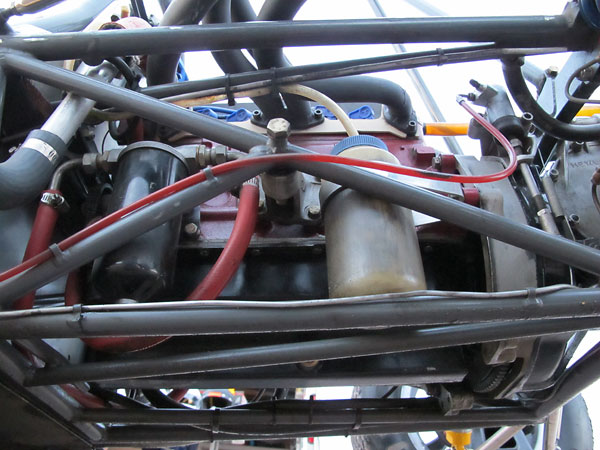

Engine coolant has been re-plumbed to external lines. Previously it ran through

�

longitudinal frame tubes, as on many other racecars of the era.

�

�

Dry sump oil pan. Large canister oil filter.

�

�

The car's original radiator featured a built-in oil cooler, so it wasn't out of the way

�

to mount the engine oil reservoir in the nose of the car.

�

�

Mocal 10-row aluminum oil cooler.

�

�

Overflow / breather tank.

�

�

Hewland Engineering Limited Maidenhead, serial number H8-903.

�

�

Front Suspension / Etc.

��

�

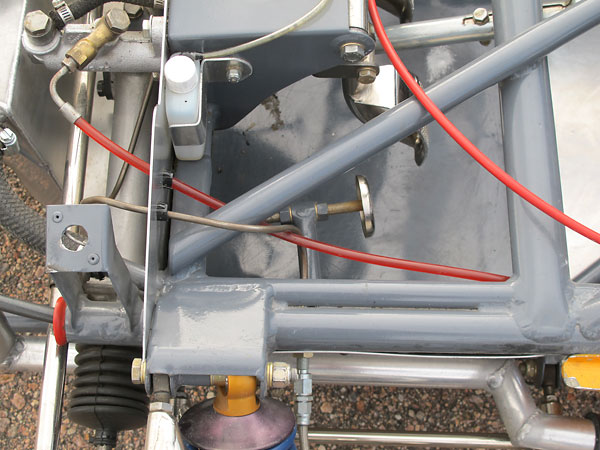

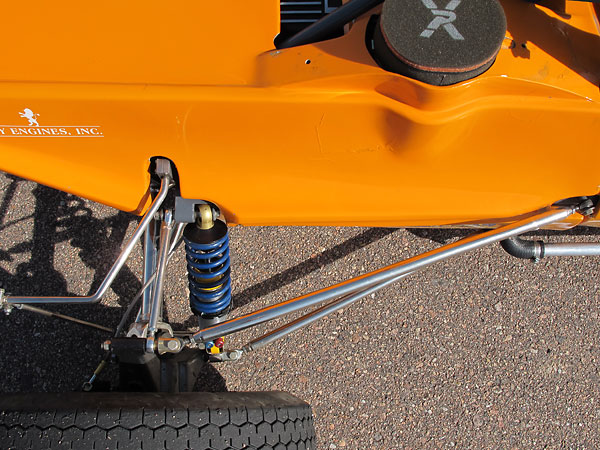

From this angle, the Titan Mk6's unequal length wishbones look perfectly traditional.

�

�

Designer Roy Thomas provided the Titan Mk6 model with Brabham BT23 style two-piece upper

�

control arms. When braking, the rearward piece is loaded in tension and the forward piece is

�

loaded in compression, which explains their relative cross-sections. Moreover, the rearward

�

pick-up has been moved to a more robust part of the frame.

�

�

Imagine a line drawn through the upper and lower pivots of the front upright. It's not perpindicular to

�

the ground. Its angle to a perpindicular reference is called "kingpin inclination". Six to eight degrees

�

is typical. Now extend the imaginary line to the ground. The distance from where it touchs the road

�

to the center of the tire's contact patch is called "scrub radius". Four inches is typical for vintage

�

racecars. Kingpin inclination and scrub radius affect steering effort and driver feel.

�

�

Alford & Alder (Triumph Spitfire pattern) forged uprights.

�

�

SPAX double-adjustable coilover shock absorbers.

�

�

When Andy restored this Mk6 (~10yrs ago), he hired Front Range Motorsports to handle chassis repairs.

�

�

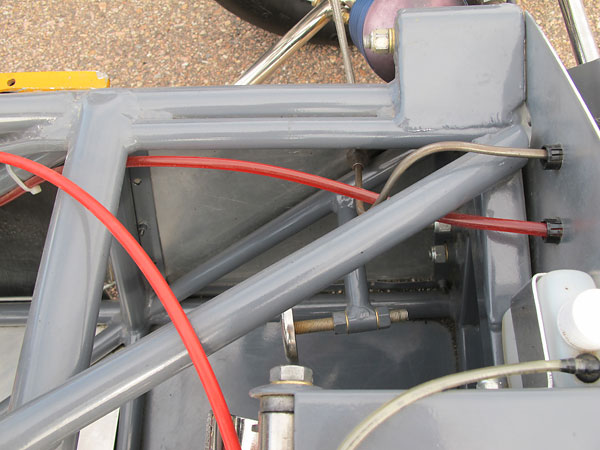

Frame construction details. Note oval cross-section tubes, doubled tubes,

�

and out-of-plane diagonal stiffener.

�

�

Adjustable dead pedal.

�

�

Throttle pedal mounting features positive stops for both forward and extent of travel.

�

�

This car's nifty fabricated steel brake fluid reservoirs are period correct.

�

The brake fluid overflow catch bottle is probably a newer improvement.

�

�

IMPORTANT ANNOUNCEMENT

�

BritishRaceCar.com will have to cut back plans for continued growth if we can't find more financial support.

�

If you like what you've found here, and you want to see more, please click here and follow the instructions.

�

Readers like you keep BritishRaceCar.com online and growing through voluntary financial contributions.

�

Rear Suspension

��

�

No surprises here: inverted lower wishbones, single top links, twin trailing links.

�

�

In one respect the Titan Mk6 suspension is typical for its era: it seems no attempt was made to

�

minimize frontal area or coefficient of drag. Later Formula Fords are much more streamlined.

�

�

SPAX double-adjustable coilover shock absorbers.

�

�

This rear anti-sway bar appears to provide a very wide range of adjustment.

�

�

Interior

��

�

Sabelt six point cam-lock safety harness.

�

�

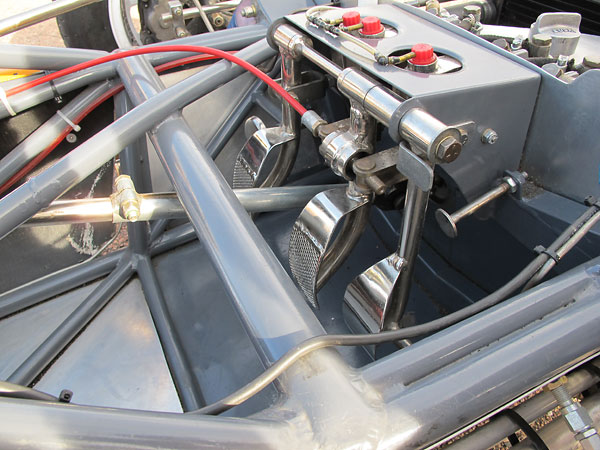

At left: Tilton cable operated brake bias adjuster.

�

�

Spa Design quick release steering wheel hub, part number 01827300150.

�

�

Stewart Warner coolant temperature gauge (100-240F) and oil pressure gauge (5-100psi).

�

Smiths Chronometric tachometer (500-8000rpm).

�

�

Andy Antipas's Titan Mk6 is marked with car serial number 73677.

�

The frame is also stamped with an Arch Motors number: AM 73/10.

�

�

Gear shifter knob.

�

�

The floor of the footbox is steel. Further back, the car has an aluminum floor.

�

�

Diagonal braces to the main rollhoop were added to keep this particular Titan Mk6 in compliance

�

with Sports Car Club of America safety requirements from years after it was built.

�

Modifications like this are badges of honor. This car was worth updating.

�

�

The roll hoop braces pivot out of the way for drivers seat removal.

�

�

Lower brace mounting bracket.

�

�

Another safety enhancement: a taller roll hoop has been installed over the scuttle and sturdily braced.

�

�

Original Titan fiberglass drivers seat.

�

�

FireBottle Halon centralized fire supression system.

�

�

Odyssey PC545 sealed/nonspillable drycell battery.

�

�

Fuel Safe under-seat, wedge-shaped fuel cell.

�

�

Exterior

��

�

Fellow Rocky Mountain Vintage Racing member John Brosseau wishes Andy good luck.

�

�

We enjoyed watching Andy win the first Group 3 race of Rocky Mountain Vintage Racers'

�

"Octoberfast" weekend at Pike's Peak International Raceway, October 29, 2011.

�

Andy circled the 1.400 mile circuit with a best lap time of 1:04.844,

�

which works out to an average speed of 77.73 miles per hour.

�

�

As the Titan marque's registrar, Andy tries to keep informed of the whereabouts of the 364 original

�

Titan racecars. Andy can tell you where about 170 of them currently are. He personally owns two.

�

His other car is the one-of-a-kind Titan Mk3a built for Ben Moore and sometimes driven by Charles

�

Lucas in Formula Three races during 1969 (i.e. chassis number 68317, frame number AM-26).

�

�

Andy painted this Titan Mk6 himself. He selected the paint scheme - orange with a broad white

�

stripe - to honor the 1972 Team Titan semi-works racing team of Derek Lawrence and Ken Bailey.

�

�

Andy's business - Titan Motorsport North America, LLC - offers a range of service parts

�

for Titans and other Formula Ford racecars, plus helmets and safety harnesses.

�

�

Stickers (left to right): "Ivey Engines Inc.", "Rocky Mountain Division Championship Series",

�

"HSR West (Historic Sportscar Racing West)", "Fred Opert Racing", "In Memory of Roy Thomas

�

(1935-2001) Charles Lucas Engineering, Titan Cars, Chequered Flag, Tom The Weld",

�

"FF Legal and Proud", "Team Titan", "Spax", "Sabelt", "Pipercross Performance Air Filter",

�

"Red Line Synthetic Oil", "Sports Car Club of America".

�

�

Stickers (front to rear): "I Support The Workers - Milwaukee" (Sports Car Club of America),

�

"Sports Car Club of America", "RMVR Ltd." (Rocky Mountain Vintage Racing), "High Plains

�

Raceway Founding Contributor", "Danny Collins (1929-2004) May the road rise up to meet you."

�

�

Bodywork by Specialised Mouldings Ltd., England

�

�

Pipercross foam air cleaner. Lucas battery disconnect switch.

�

�

Fred Opert Racing is one of the two companies that imported Titans to North America.

�

The company has been in continuous operation since 1965.

�

�

American Racing "Silverstone" 8-spoke alloy wheels.

�

�

Avon Formula Ford / ACB9 racing tires (5.0/22.0/13 front, 6.5/23.0/13 rear).

�

| Notes: | ||

| (1) | �

Charles Lucas Engineering built two one-off racecars before developing the Titan Mk3 model�

and offering it for public sale. The name "Titan" and the model designations "Mk1" and�

"Mk2" may not have occurred to company owner Charles Lucas or to designer Roy Thomas until�

after they were well along with plans for the Titan Mk3.�

� The Titan Mk1 was reportedly a sports racer, either similar to or built from a Lotus 23.� Unlike the Ford-powered Lotus 23 that Charles Lucas drove on some occasions in 1965, the� Titan Mk1 was reportedly powered by a 2.5 liter Maserati engine. We've been unable to� confirm rumours that the Titan Mk1 may have been raced by Swedish driver Picko Troberg.� � The Titan Mk2 was in a fact a Lotus 35 Formula Two racecar (#35/F/19) modified to accept� a Martin 3-liter aluminum V8 engine. As mentioned in Motor Racing magazine's November 1966� edition: "Piers Courage was due to drive the new Lotus-Martin V8, a modified monocoque� single seater powered by Ted Martin's new GP engine, at the Snetterton Autosport Trophy� meeting on October 16. The car is being sponsored by Charles Lucas."� After a few warm-ups, Charles Lucas Engineering clearly hoped to compete in Formula One races.� The Lotus-Martin was completed in time for Roy Pike to enter the 1966 Boxing Day Formula� Libre race at Mallory Park, and he finished third on a rain soaked track. The car's second� appearance would have been the non-chamionship Formula One "Race of Champions" contest on� March 12, 1967 at Brands Hatch. Piers Courage qualified 14th quickest, but he suffered an� engine failure and did not start. Again, race reports from the Brands Hatch weekend identified� the car as a Lotus-Martin. We've also seen it referred to as a Lucas-Martin. In April,� while testing at Snetterton, Piers Courage suffered a shunt which set the Lotus-Martin on fire.� He emerged unhurt, but Charles Lucas declared the car a total loss. It may be that he made� an executive decision to focus on the new Mk3, which was nearly complete. A year later he� advertised the Lotus-Martin for sale.� � | |

�

All photos shown here are from October 2011 when we viewed the car at RMVR's October "Spooktacular" Event�

at Pike's Peak International Raceway, near Colorado Springs.�

Photos by Curtis Jacobson for BritishRaceCar.com, copyright 2012. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Bill Bovenizer '68 Titan MkIII | �

| �

Scott Fairchild '72 Royale RP3A | �

| �

Gord Leach '73 Hawke DL11 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�