�

�

Photo by Michael Casey-DiPleco. Used by exclusive permission.

�

�

Bob Girvin's Hemi-Powered 1958 Allard GT Coupe

� � Owner: Bob Girvin� City: Holliston Massachusetts

� Model: 1958 Allard GT coupe

� Engine: 1958 Chrysler 300D (392cid) V8

� Race prepared by: owner�

�

The Allard Motor Company, Ltd.

��

When car enthusiasts think of the Allard marque, the J2 model comes to mind first even though it�

accounted for only five percent of the company's production. The company's best selling models were�

four seat tourers - the M drop head coupe and the P1 saloon - but the company's reputation was�

earned by high-powered racing cars. Allard made a strong impression on European fans when�

company owner Sydney Allard and American co-driver Tom Cole Jr. piloted a Cadillac V8 powered J2�

to a third place finish in the 1950 24 Hours of Le Mans. Allard made a similarly strong impression�

in America where J2 racecars scored impressive victories at Bridgehampton, Sebring, Watkins Glen,�

and other early road racing venues.�

�

In the earliest days of American road racing, Jaguars came with Jaguar engines and Ferraris came�

with Ferrari engines but an Allard could be special ordered with almost any big American V8.�

Power to weight ratio was the J2's main advantage. With a flat-head Ford (4.2L/255cid) V8 fitted,�

a J2 only weighed about 1700 pounds. The huge Cadillac (5.4L/331cid) V8 brought weight to about�

2050 pounds. Loose rules benefitted Allard; the words "with engines over three liters" covered a�

lot of ground! Allard J2 racecars roared to many victories, and captured the imagination of a�

generation of fans.�

�

The Allard story didn't start with the J2 model. It began in the pre-war years when Sydney Allard�

set up a Ford car dealership in south London and began spending his weekends building, racing, and�

improving a Ford Model 48 based "special" in various trial and hillclimb events. He was tremendously�

successful in trials, and other enthusiasts begged him to build racecars for sale. He consented.�

Sydney Allard and his crew built eleven Ford-powered specials before the war, and completed a twelfth�

shortly after hostilities ended. (In the intervening years, the Allard shop had been busy repairing�

and rebuilding Jeeps and other light vehicles for the war effort.) Experience with Ford-Powered�

specials was applied to a single fantastic Steyr-powered special with which Sydney Allard dominated�

the 1949 British Hill-Climb Championship. We'll take a close-look at the Steyr-Allard in a future�

article, when we can better illustrate how its design led to the J2 model.�

�

One key to the success of Sydney Allard's early specials was that he commissioned Leslie Ballamy�

to design an independent front suspension. Ballamy's split-axle design gave Sydney Allard's racecars�

superior braking on rough surfaces compared to rival cars with solid front axles. Ballamy's front�

suspension concept was used on all Allards through 1954, although details varied. (For example,�

leaf springs were replaced with coil springs.)�

�

Allard Motor Company Limited was founded in 1946. Racing was Sydney Allard's first love, and the first�

mission of the car company was to keep Sydney Allard in competitive racecars! �

�

A large proportion of Allard's cars were shipped to America. The British government worked hard after�

the war to promote exports. In reward for exporting cars, Allard was granted priority access to�

materials for production (and thus for racing.) Through the dealership, Allard Motor Company also�

had access to Ford parts. They never attempted to develop their own engines because it made better�

sense to use Ford engines. When customers wanted other engines, Allard worked to support those�

requests. Some Allard cars were shipped without engines to New York, and completed there. �

�

Allard Models and Production Figures

�| Competition Cars | Sports Cars | Touring Cars¹ | |||||||||

| Model | Years | # Built | Model | Years | # Built | Model | Years | # Built | |||

| J1 | 1946-48 | 13 | K (K1) | 1946-48 | 151 | L | 1946-48 | 191 | |||

| Steyr-Allard #1 | 1949 | 1 | K2 | 1950-51 | 119 | M | 1947-50 | 500 | |||

| J2 | 1949-51 | 90-99 | K3 | 1953-54 | 63 | P (P1) | 1949-51 | 559 | |||

| J2X | 1952-54 | 77-83 | Palm Beach | 1952-54 | 74 | P2 Monte Carlo | 1952 | 11 | |||

| J2X Le Mans | 1952-53 | 10-11 | Palm Beach Mk2 | 1956-58 | 6 | P2 Safari Estate | 1952 | 10 | |||

| JR | 1953-54 | 7 | GT Coupe | 1958 | 2 | ||||||

| Atom (500cc) | 1955 | 2 | Micro Cars | ||||||||

| Steyr-Allard #2 | 1958 | 1 | Clipper | 1954-55 | 5 | ||||||

| Subtotal: 201 to 217 cars | Subtotal: 414 cars | Subtotal: 1276 cars | |||||||||

| Grand Total: 1891 to 1907 cars | |||||||||||

�

Allard Motor Company went from success to success through a half dozen years. One of�

the company's greatest victories was in the 1952 Monte Carlo Rally when Sydney Allard�

and Guy Warburton co-drove an Allard P1 saloon along with navigator Tom Lush to a�

first place finish. (Second place went to a young team composed of drivers Stirling Moss�

and Desmond Scannel with navigator John Cooper, in a Sunbeam-Talbot 90.)�

�

Generally, racing victories led to customer orders but the connection seemed to come apart in�

the early fifties. The car market was in turmoil. Styles and technology were changing especially�

quickly, and all car companies were obliged to rush new models to market. In 1952 Allard introduced�

a new lower-priced two-seat sports car called "Palm Beach" and they followed up in January 1953 with�

an updated K model. Whereas the K3 was available with a variety of American V8 engines, the�

Palm Beach came with either British Ford's Consul four-cylinder or Zephyr six-cylinder.²�

Both of these new sports cars featured smooth aluminum bodies on multi-tube steel frames. Hopes were�

high, but sales weren't. In total, only sixty-two K3 sports cars and seventy-four first-generation�

Palm Beach sports cars were produced. �

�

Allard continued building cycle-fendered competition cars too. The J2 model was replaced by�

a newer version called J2X; although the wheelbase dimension was unchanged, the frame was extended�

at the front to support trailing radius rods and engines (either Chrysler or Cadillac V8-type)�

were shifted forward 7.5 inches relative to the body. For 1952, Le Mans rules changed to�

explicitly prohibit cycle fenders so Allard created an envelope-bodied "J2X Le Mans" variant.�

The final model in the competition series was the JR, which was a new and even more ambitious�

racecar for 1953.�

�

Allard's new models were far less successful than Jaguar's XK-120 range. Furthermore, Allard's�

niche was invaded in 1951 by the Nash-Healey. In many respects the Nash-Healey was similar�

in concept and execution to the Palm Beach, but it was available in America through a nationwide�

dealer network. New sportscar models were coming fast and furious. Kaiser introduced�

the stunningly beautiful Darrin, Chevrolet introduced the Corvette, BMC introduced the�

Austin-Healey 100. Sydney Allard undoubtedly knew Ford would soon have a sporty model of�

their own. Allard Motor Company needed a partner for marketing and distribution in North America,�

but inquiries with Studebaker and negotiations with Chrysler were ultimately fruitless.�

�

Production ground to a stop at the end of 1954, even as Sydney Allard planned technical updates�

and styling changes to make the Palm Beach more commercially attractive. The plant was almost�

completely idle through 1955, but there was a reprise of activity in 1956. Allard announced they�

were back on the market with a Mark Two version of the Palm Beach model, featuring more curvaceous�

styling.�

�

For the Palm Beach Mk2, the Allard Motor Company dispensed with the split-axle front suspension�

which had been used on all previous models. Instead, they developed an unusual hybrid design�

which featured aspects of a MacPherson strut suspension (as had been pioneered on the British Ford�

Consul and Zephyr models) in combination with torsion bar springs a la Jaguar. Instead of making�

telescoping shock absorbers integral to the "strut" pillars, they were mounted on the rearward�

arms of wide-based lower A-arms. Whereas MacPherson struts are usually mounted at their very top to�

inner wings (i.e. "fender wells"), on the Allard they were by necessity pivoted from brackets off�

the frame. Allard's new suspension was compact, tunable, and had a relatively low unsprung weight.�

�

The improvements weren't enough. Only eight more cars were built, six convertibles plus two�

Gran Tourismo coupes. The first GT was to be Sydney Allard's personal car. Breaking tradition,�

Sydney Allard had it fitted with a six cylinder, 3442cc Jaguar engine. �

�

�

�

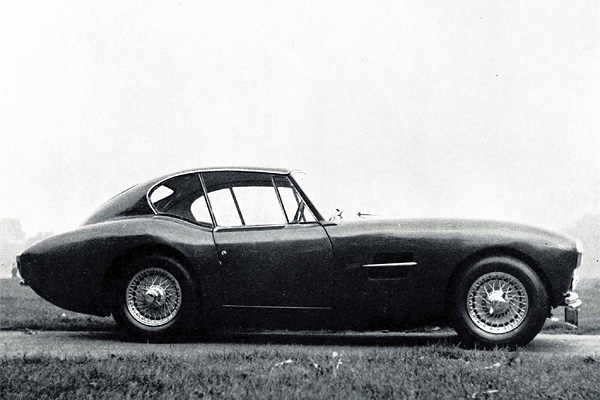

Sydney Allard's GT coupe, as it appeared in company literature. After Sydney Allard entered

�

his GT in the Production sports car class at Stapleford on 12 October 1958, Autosport magazine

�

reported: "Triumphant amongst the largest sports cars was Sydney Allard driving his very

�

beautiful GT creation which has a Jaguar engine". (Richard Page assisted our research.)

�

�

�

�

�

�

The Second of Only Two Allard GT Coupes Ever Built

��

The second and final GT coupe was purchased by then 22-year-old Willis Harrington du Pont, the�

youngest of Lammot du Pont Jr.'s ten children. One of the richest and most powerful men in�

the world, Lammot du Pont Jr. had been President of E.I. du Pont de Nemours and Company from�

1926 through 1940 and also President of General Motors Company from 1929 through 1937, besides�

serving on many boards of directors. Lammot had died in 1952, leaving Willis a very large fortune.�

(Interestingly, Willis was named for the du Pont engineering executive who made the executive�

decision to produce tetraethyl lead, the gasoline additive. Willis' older brother David F.�

du Pont had died in 1956 as a result of an automobile accident.) �

�

Like Sydney Allard's GT, the "du Pont GT" was originally built with a Jaguar engine. However,�

Willis du Pont wanted something with more pep, so he arranged to have a larger engine�

installed. In fact, he supplied an aggressively race-prepared Chrysler 392cid "hemi" V8 engine�

to the Allard works for the car's completion.³�

�

When Willis du Pont arrived to review his car, he was reportedly disappointed that it wasn't as�

refined as a Facel Vega. A different engine might make the GT more suitable for touring, but a�

complete redesign (and roughly fifteen hundred pounds of ballast) would have been required to�

transform the Allard into a luxury barge. �

�

Within three weeks of its arrival in the United States, the du Pont GT's engine was replaced�

again, this time with a standard 1958 Chrysler 300D motor. Incidentally, that engine is now�

kept safely in storage, while a different 300D motor is used for vintage racing.�

�

The du Pont Allard GT was used as a street car through the early 60s, and we've been unable�

to find any evidence it was raced in that period. We don't know when Willis du Pont sold it.�

In 1968 it was taken in trade on a Ford Thunderbird from a man who is rumoured to have had�

Mafia connections; he reportedly told the dealer that he had won the Allard GT in a card game.�

A Buick dealer in New York took it in trade in 1975 and restored its paint and interior.�

�

�

�

ALLARD - Type / Chassis No. 82CT7105CH

�

Allard Motor Company Ltd. - Regd. Office, London, England.

�

Telegraphic address: ALMOTCO LONDON

�

Racing Allard Chassis Number 82CT7105CH

��

Bob Girvin bought his Allard in 1982. He rebuilt the chassis and driveline, installed a roll�

cage, and otherwise prepared the car for vintage racing. Bob Girvin has been enthusiastically�

racing the car throughout the eastern United States ever since. For most of those thirty years,�

Bob has run ten or twelve races per year. In 2010 he only ran five, and in 2011 he only ran one.�

Of the GT, Bob says: "It's hot and heavy, and a lot of work to drive." But clearly he enjoys it�

immensely. He has especially enjoyed tinkering with technical details like brakes and suspension;�

things the Allard Motor Company would have focused development effort on if they had stayed in�

production longer. �

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

Features and Specifications

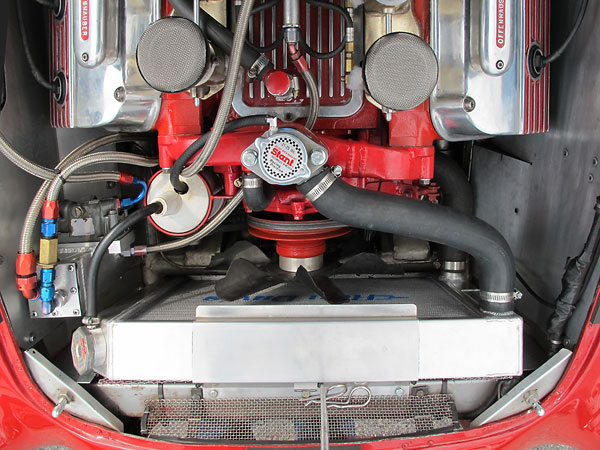

�| Engine: | �1958 Chrysler 300D "hemi" (392cid) V8 engine, producing about 515bhp at 5800rpm.�

Rebuilt by Bob Girvin with machine work by A.B.T. Machine Co. of Holliston MA.�

Hilborn fuel injection.�

BBR Max Flow stainless steel velocity stack filter covers.�

Mallory Unilite distributor.�

MSD6AL capacitive discharge ignition system.�

Mallory "Electronic" ignition coil.�

MSD 8mm heli-core solid supppression spark plug wires.�

Moon aluminum valve covers with Offenhauser breathers.�

Custom deep sump aluminum oil pan.�

13-row aluminum engine oil cooler.�

| �

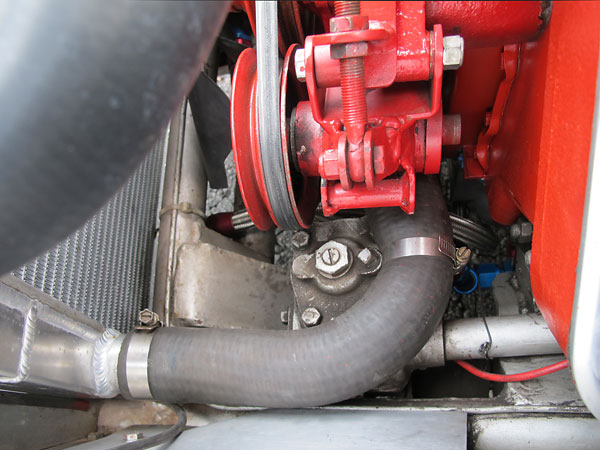

| Cooling: | �Ron Davis custom aluminum dual-pass crossflow radiator.�

Engine driven flex fan. | �

| Exhaust: | �custom four-into-one headers by Tubular Automotive Custom Exhaust of Rockland MA. | �

| Transmission: | �Borg-Warner T10 4-speed, iron case.�

(Clutch actuated via mechanical linkage.) | �

| Rear End: | �Dana 44, originally fitted with an open differential but now competing with a limited slip differential.�

3.54:1 gear ratio.�

Red Line "Shockproof" gear lubricant. | �

| Front Susp.: | �(See article text and photo captions for detailed description.)�

Adapted Chrysler torsion bar springs. �

SPAX gas-filled, adjustable, telescoping shock absorbers.�

Beefy non-adjustable anti-sway bar.�

Marles high ratio steering gear. | �

| Rear Susp.: | �De Dion tube mounted on four trailing links, with a Panhard rod.�

Coil springs.�

KONI steel-bodied double-adjustable telescoping shock absorbers.�

Adjustable anti-sway bar mounted on aluminum pillow blocks. | �

| Wheelbase: | �96 inches. | �

| Brakes: | �(master) dual Tilton master cylinders (3/4" front and 5/8" rear) with bias bar. � (front) Girling CR brake calipers, on 12" rotors. � (rear) inboard mounted drum brakes with Buick aluminum drums. | �

| Wheels/Tires: | �Dayton 72-spoke cross-laced wire wheels.�

Avon CR6ZZ 205/70R15 96V tires. | �

| Electrical: | �Delco-Remy alternator.�

Filko external voltage regulator.�

Lead-acid battery. | �

| Instruments: | �(left to right)�

AutoMeter Pro-Comp oil temperature gauge (140-280F),�

AutoGage water temperature gauge (100-280F) for lefthand cylinder head,�

AutoGage water temperature gauge (100-280F) for righthand cylinder head,�

unbranded digital thermometer,�

AutoMeter Sport-Comp Monster tachometer (0-8000rpm),�

Smiths petrol level gauge,�

Smiths dual oil pressure (0-100psi) and water temperature (30-100C) gauge,�

Smiths ammeter (+/- 30 amps), and a�

Smiths speedometer (0-150mph).�

| �

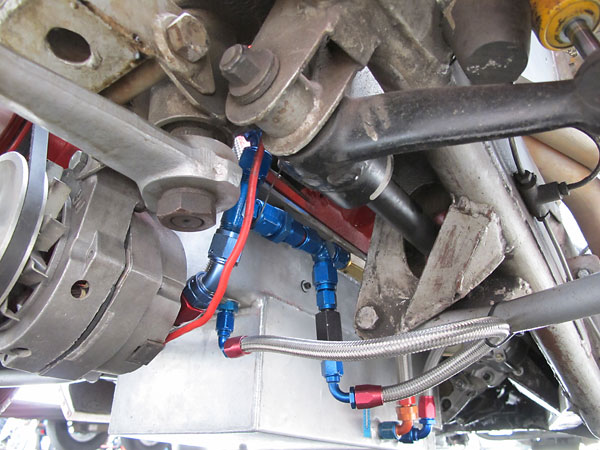

| Fuel System: | �ATL SP115 15 gallon steel canister fuel cell.�

Hilborn mechanical fuel pump (as required for proper function of the fuel injection system.)�

Holley "blue" rotor/vane electric fuel pump (to fill a make-up tank in the engine compartment.)�

Holley adjustable fuel pressure regulator, with AED fuel pressure gauge (0-15psi). | �

| Safety Eqmt: | �Schroth six point cam-lock safety harness.�

Kirkey aluminum dragster drivers seat, cut down for use with separate headrest.�

Centralized fire suppression system.�

Three different rear view mirrors. | �

| Weight: | �~2850 pounds, dry. (52/48 distribution.) | �

Engine Installation

��

�

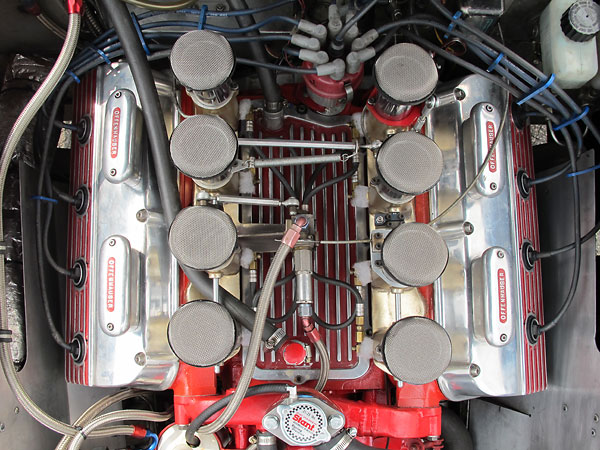

1958 Chrysler 300D "hemi" (392cid) V8 engine, producing about 515bhp at 5800rpm. The name hemi

�

refers to the hemispherical shape of combustion cavities cast into the cylinder heads.

�

�

Although Bob Girvin isn't absolutely certain, it's most likely that his Allard GT was equipped

�

with dual four-barrel carburetors when it was originally constructed. The Hilborn fuel

�

injection set-up that's on the car now was developed and produced earlier in the 1950s.

�

�

The throttle body castings are marked: "Hilborn Injection - Los Angeles - Pat Pend".

�

Atop the velocity stacks: BBR Max Flow stainless steel filter covers.

�

�

Hilborn fuel injection systems are still available brand new! Bob reports: "The engine idles

�

nicely at 700/800rpm and pulls well from 1000rpm to 6500rpm, at full or part throttle."

�

�

Mallory Unilite distributor, and MSD 8mm heli-core solid supppression spark plug wires.

�

�

The Allard GT coupe was originally built with dual (i.e. separate front and rear) Girling master cylinders

�

but Allard didn't provide any convenient to use mechanism for brake bias adjustment. Bob Girvin made the

�

modest upgrade of adding an adjustable bias bar mechanism when he fitted these Tilton master cylinders.

�

�

MSD6AL capacitive discharge ignition system, with 6600 rpm rev-limiter chip installed.

�

�

Mallory "Electronic" ignition coil. (Note: ballast resistor in foreground is disconnected.

�

It will be required if Bob goes back to using a conventional Chrysler ignition system.)

�

�

Delco-Remy alternator.

�

�

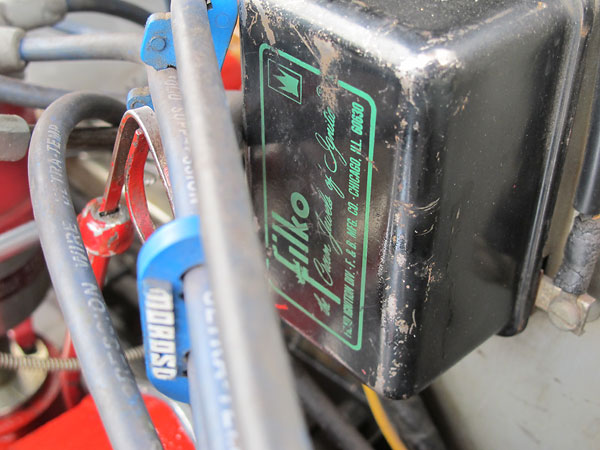

Voltage regulator for the alternator, labeled: "Filko - the Crown Jewels of Ignition

�

Filko Ignition Division, F&B Mfg. Co., Chicago IL., 60630"

�

�

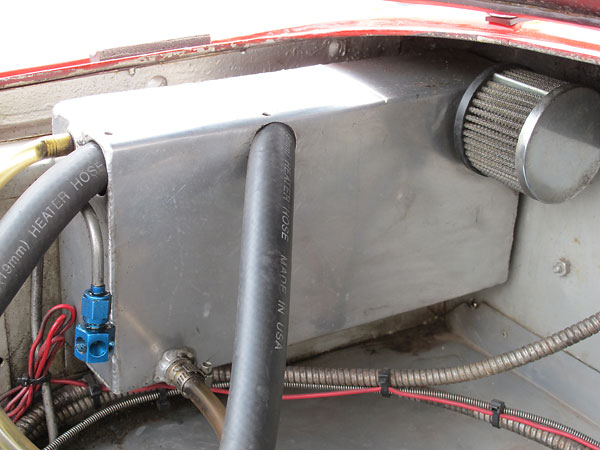

Custom fabricated aluminum crankcase breather tank.

�

�

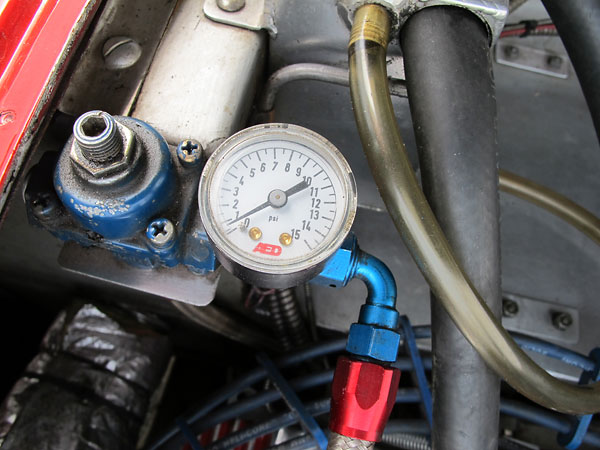

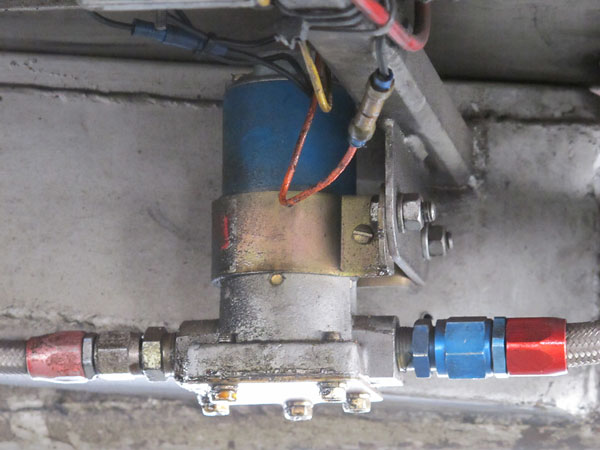

Holley adjustable fuel pressure regulator, with AED fuel pressure gauge (0-15psi).

�

�

In this view, the supply line to the custom aluminum fuel make-up tank comes in from the right.

�

It's connected to a primary float bowl borrowed from a center-hung-float Holley carburetor. Inside

�

the float bowl, a hollow brass float operates a valve to control the level of fuel in the surge tank.

�

�

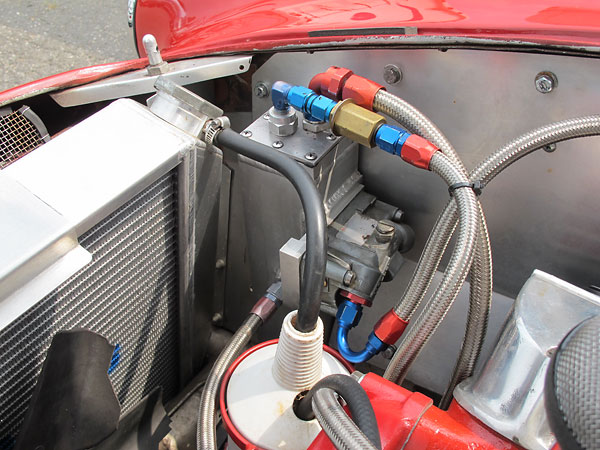

Underneath a coolant overflow bottle (at left), a Hilborn positive displacement fuel pump is driven at

�

one-half crankshaft speed. (Three of the Aeroquip stainless steel braided fuel lines in this view are

�

routed to it.) See the hexagonal brass fitting above the surge tank? A removable orifice inside that

�

fitting is the primary means for tuning fuel mixture! It's on the overflow line from the barrel valve to

�

the fuel injectors. A smaller orifice here forces more fuel to the injectors for a richer air/fuel mixture.

�

�

Ron Davis custom aluminum dual-pass crossflow radiator. Engine driven flex fan.

�

�

In thirty years of racing, Bob has tried a few radiators. He reports that this latest one is a major

�

upgrade. It's a double-pass design: coolant flows right-to-left across the bottom half, then

�

left-to-right across the top half. Compared to the otherwise similar radiator it replaced,

�

coolant temperature has been cut from 220F to 180F - even with two rows of tape applied.

�

�

13-row aluminum engine oil cooler.

�

�

Bob Girvin designed and fabricated this custom deep sump aluminum oil pan.

�

�

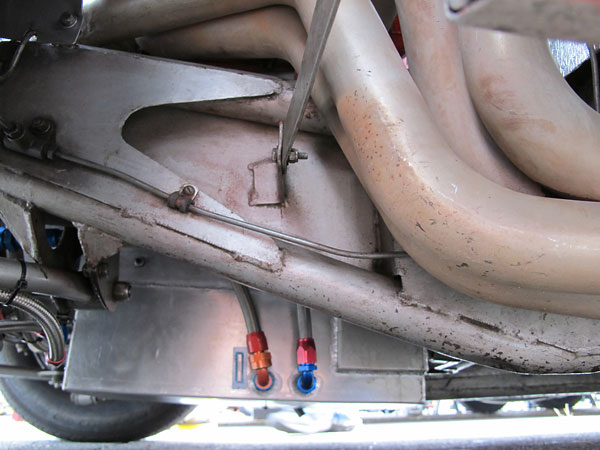

Custom stainless steel four-into-one headers by Tubular Automotive Custom Exhaust of Rockland MA.

�

�

IMPORTANT ANNOUNCEMENT

�

BritishRaceCar.com will have to cut back plans for continued growth if we can't find more financial support.

�

If you like what you've found here, and you want to see more, please click here and follow the instructions.

�

Readers like you keep BritishRaceCar.com online and growing through voluntary financial contributions.

�

Front Suspension

��

�

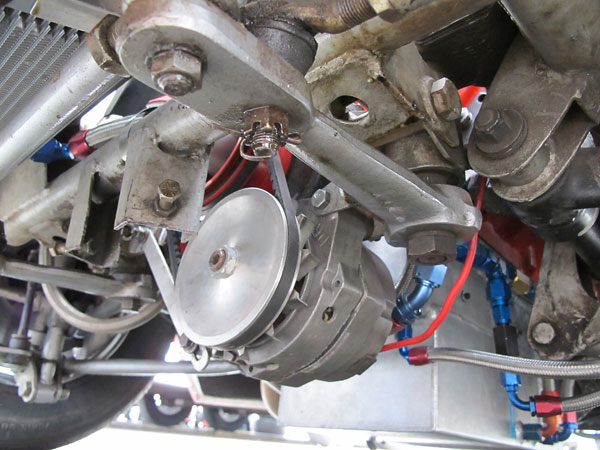

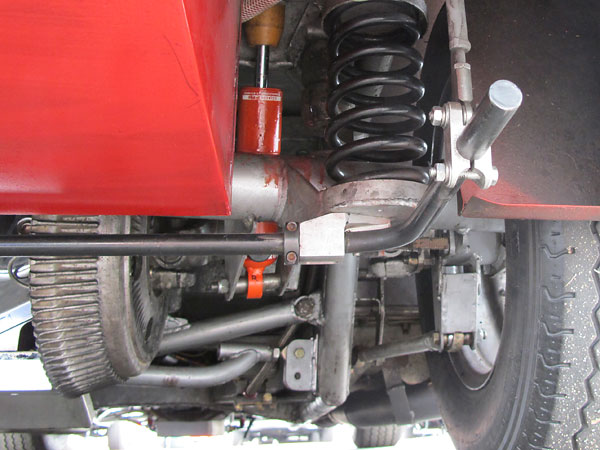

Mechanically they're very different, but in terms of their geometry the Allard GT front suspension

�

is similar to a MacPherson Strut suspension. The hub carrier is located by a wide-based A-arm at

�

its bottom. The kingpin pivots at the top on a bracket off of the frame. A torsion bar spring, a

�

telescoping shock absorber, and an anti-sway bar are all connected to the A-arm.

�

�

The original Allard torsion bar springs proved far too soft for competition use, so Bob Girvin

�

adapted Chrysler torsion bar springs to the job.

�

�

SPAX gas pressurized, adjustable, telescoping shock absorbers.

�

�

The upper end of the kingpin slides in a tube, and the tube is mounted so it can pivot in one axis.

�

As you can see, the pivot mounting bracket has been drilled for two mounting patterns. By shifting

�

between mounting holes, Bob can select two different tire camber range settings.

�

�

Allard used Marles steering gears throughout their production period.

�

�

Steering linkage. Note adjustable positive stops.

�

�

Tow eye and brake cooling duct.

�

�

Rear Suspension

��

�

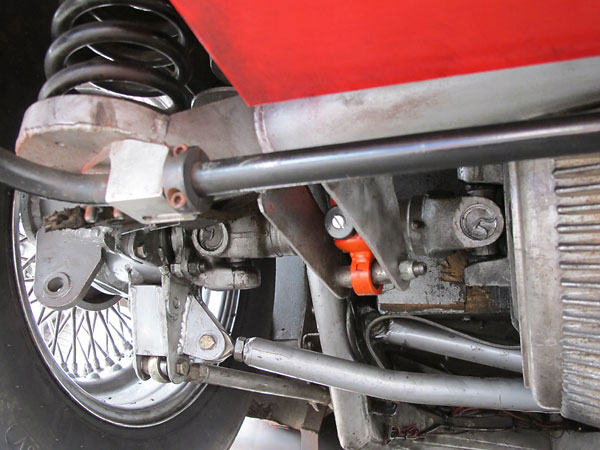

This rear suspension was carried over from the JR model (seven of which were made, the first of which

�

debuted at Le Mans in 1953.) Bob's understanding is that eight Allard JR racecars were planned but only

�

seven were built, and that the one surplus JR De Dion suspension was therefore used on his GT coupe.

�

�

Like a solid (live) axle, a De Dion tube keeps wheels parallel to each other and perpindicular to the

�

road. Principle advantage: much lighter unsprung weight, which benefits ride quality and road holding.

�

�

Adjustable anti-sway bar mounted on aluminum pillow blocks.

�

�

KONI steel-bodied double-adjustable telescoping shock absorbers.

�

�

Allard originally installed British "Al-Fin" (aluminum finned) brake drums. The original drums are scarce

�

and exhorbitantly expensive if you can find them. Bob uses a period-correct substitute: Buick aluminum

�

brake drums. Buick provided 12" aluminum front brake drums on larger car models from 1958-70. Early

�

Buick aluminum brake drums had 45 fins. From ~1966, Buick switched to 90 more closely spaced fins.

�

�

A Panhard rod connects lefthand side of the rear suspension to righthand side of the car's frame.

�

To the right, a small aluminum panel directs passing airflow upward to cool the inboard brakes.

�

�

This blue Thermax decal indicates the maximum temperature its mounting surface has ever reached.

�

Normal synthetic gear lube should provide good protection to at least 250°F. Where higher temps

�

exist preventive maintenance, an oil cooler, or special lubricant is advisable. Upon close inspection,

�

this Thermax decal has has reached ~280°F, but it's not really a surprise that a hemi-powered racecar

�

might qualify as a "severe service" application. Bob uses Red Line's Shockproof gear lube, which is

�

rated for 300°F! To the right, "3.54" is the ring and pinion gear ratio.

�

�

These American-made Dayton wheels have extra robust splines (as on Jaguar E-type) plus

�

oversize spokes and nipples. Their "cross-laced" spoke arrangement has proven key to

�

their durability. Before Bob knew to specify cross-laced spokes, new wheels only lasted

�

two or three seasons. His cross-laced wheels have lasted about seven seasons, so far.

�

�

The Allard GT frame is elaborate enough that we won't attempt to describe it - photos will

�

serve you better - but generally, from the Palm Beach model (of 1952) onward Allard frames

�

featured twin tubular side members coupled together at intervals by steel plates. It's been

�

reported that Allard was one of the first car companies to use chrome-moly tubing, but we

�

can't advise exactly which car models or components used that higher-strength alloy steel.

�

�

The De Dion tube is connected to the chassis by four trailing links. Bob has upgraded them

�

with Heim joints to facilitate precision alignment and suspension tuning.

�

�

Coil springs.

�

�

ATL SP115 15 gallon steel canister fuel cell.

�

�

Holley "blue" rotor/vane electric fuel pump.

�

�

Interior

� �

�

Moto-Lita steering wheel.

�

�

(left to right) AutoMeter Pro-Comp oil temperature gauge, two AutoGage water temperature gauges,

�

a digital thermometer, AutoMeter Sport-Comp Monster tachometer, Smiths petrol level gauge,

�

Smiths dual oil pressure and water temperature gauge, Smiths ammeter, and Smiths speedometer.

�

�

The Smiths speedometer was reading 50mph when we snapped this photo. The odometer read: "10169".

�

�

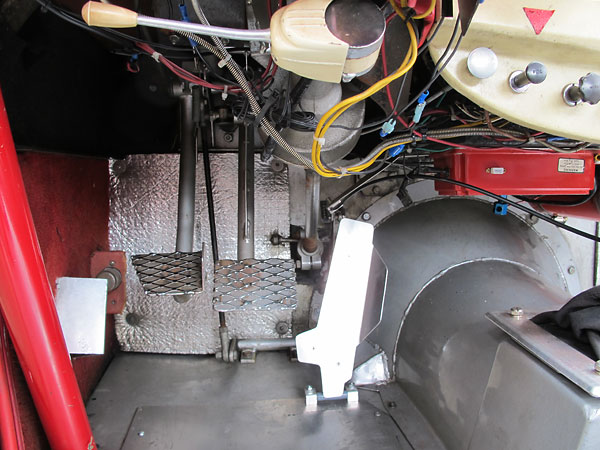

Bob fabricated the removable transmission cover out of thin steel sheetmetal. The paper label on

�

it reads: "Check list: fuel open, ignition on, fuel pump, differential pump, differential fan."

�

(Differential pump and fan were removed when Bob switched to Red Line ShockProof® lube.)

�

The black cloth gear shifter boot has the embroidered logo of Longacre Racing Products.

�

�

Bob developed a novel hand-operated throttle mechanism to help him match engine-transmission revs

�

when downshifting. Recent changes to the throttle pedal have made it obsolete, so he'll remove it soon.

�

(Note: on this shifter, the collar below the shift knob must be lifted upward to engage reverse.)

�

�

Clutch pedal works through a mechanical linkage to actuate the clutch. Note that

�

turn signal switch and (floor-mounted) highbeam switch are still installed.

�

�

Kirkey aluminum drivers seat, cut down for use with separate headrest.

�

�

Schroth six point cam-lock safety harness.

�

�

A-pillar air deflector: lower half directs airflow into the cockpit while the top half provides airflow

�

to the driver's helmet via a corrugated hose. Bob also wears a CoolShirt; the ice chest

�

for it is strapped behind the driver's seat.

�

�

Padded horizontal bars on either side of the driver's helmet.

�

�

Joseph Pollak brand battery disconnect switch. Custon aluminum bracket for a video camera.

�

�

Aluminum battery box.

�

�

Exterior

��

�

Photo by Greg Nichols. Used by exclusive permission.

�

�

�

At the 2011 Lime Rock Historic Festival, Bob Girvin and his Allard GT placed second in the

�

Group 2 race for "Sports Racing Cars of the 1950s", defeating a number of purpose-built

�

racecars including pair of excellent Lola Mk1s and a 1960 Chaparral Mk1.

�

�

Alexander Racing Enterprises (A.R.E.) Lucas PL-700 tri-pod headlamp simulator decals.

�

�

Original glass windshield.

�

�

Carroll Shelby successfully drove a Cadillac powered Allard J2 racecar throughout the 1953 season,

�

before being recruited to drive for the Aston Martin works racing team. He continued driving for

�

Aston Martin until 1960. It was only after that time, specifically September 1961, that Shelby started

�

working with AC Ltd. on a project that would become the famous Cobra. What really differentiated

�

Shelby's Cobra over its predecessors, like Allard? Shelby's timing and marketing prowess.

�

�

�

The du Pont Allard GT was originally finished in lacquer, but it wears acrylic paint now.

�

Bob only trusts the car to expert bodyman and fellow racer Eno DePasquale.

�

�

As shown in the photo at the top of this article, Sydney Allard's GT Coupe didn't

�

have external door handles. Small differences from car to car are one of the

�

delightful charms of vintage and bespoke automobiles.

�

�

The Allard GT's original taillamps were common with a Rover saloon design,

�

but the lamps shown here are common semi-trailer stop/turn/tail lamps.

�

�

An ATL SP115 15 gallon fuel cell is accessed for refueling by releasing five Dzus

�

quarter-turn fasteners and removing the lid that once covered a spare tire.

�

�

Dayton 72-spoke cross-laced wire wheels.

�

�

Avon CR6ZZ 205/70R15 96V tires.

�

| Notes: | |||||||

| (1) | �

There's some ambiguity between "Sports" and "Touring" cars in an Allard context.�

In our table, the five models we've listed as Touring Cars featured 112" wheelbases�

and two rows of seating. The six models in our Sports Car column feature shorter�

wheelbases: 106" for the K1 and K2, 100" for the K3, 96" for the Palm Beach and GT.�

Except for the GT, the sports cars feature single rows of seating. Other sources�

may classify the models differently.�

� | ||||||

| (2) | �

Exactly one Palm Beach Touring was fitted with a Dodge Red Ram V8 engine on a�

prototype / demonstration basis. Introduced in 1953, the Red Ram engine was the�

smallest of the Chrysler Corporation's classic "hemi" head engines in terms of�

displacement (241cid) and bore spacing (4.1875"). Chrysler was interested in�

offering the new engine in a limited production sports car model.�

� | ||||||

| (3) | �

The du Pont GT originally featured an automatic gearbox. David Hooper, Chief Draughtsman�

through this period, told BritishRacecar that in his recollection it was primarily�

an inappropriately selected torque converter that made this particular car unpleasant�

on test drives around London. That account differs from what Bob Girvin has heard�

elsewhere; that du Pont provided a full-race engine that was set to idle at around�

3000rpm and was therefore unpleasant despite being coupled to a stock torque�

converter. �

� | ||||||

�

Except as otherwise credited in captions,�

all photos shown here are from September 2011 when we viewed the car at Lime Rock Park in Connecticut.�

Photos by Curtis Jacobson for BritishRaceCar.com, copyright 2012. All rights reserved.�

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Bob Millstein '51 Jaguar Spl. | �

| �

Tivvy Shenton '55 Jaguar XK140 | �

| �

Syd Silverman '59 Lister-Jaguar | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�