�

�

Eric Haga's Lola T190 Formula 5000 Racecar, Number 8

� � Owner: Eric Haga� City: Seattle Washington

� Model: Lola T190 (circa 1970)

� Engine: Chevrolet 302cid V8 engine.

� Restored by: owner.�

�

Lola's Answer to Rising Competition in F5000

��

In the early years of Formula A and Formula 5000 racing, Lola Cars Ltd. was the most �

prolific constructor. Lola's T140 and T142 models sold well and enjoyed a good reputation.�

Their only big problem was they didn't win their share of races. Between 1968 and�

1969, there were twenty-three North American Formula 5000 races and Lola cars captured�

just two wins. By the end of 1969, the spaceframe chassis of the T140 and T142 were �

looking old-fashioned compared to newer monocoque chassis from McLaren, Surtees, and �

Eagle. �

�

Lola's answer was the all-new T190. Knowing that the last race of the season is always�

remembered clearest when race teams order new cars, Lola delivered the T190 just in time. �

It would debut at the last race of 1969 in Sebring Florida on December 28, 1969. �

�

Despite arriving at the track late and missing a day of practice and tuning time for his �

brand new car, Mark Donohue managed to qualify third. The actual race was comprised of �

two 100 mile heats. Donohue dropped out of both heats due to the same problem: clogged �

under-sized fuel filters. He was in second place when he retired from the first heat, �

and in first place when he retired from the second. As Donohue later wrote: "We had �

showed everyone that we had the fastest car, but we just hadn't put enough time or care �

into the preparation."¹ Another of the teams that Lola seeded with fresh equipment �

won a spot on the podium: Jo Bonnier drove his new T190 to finish third. As 1969 ended, �

things were looking up for Lola. �

�

Probably the most interesting (and controversial) thing about the new T190 design was �

its very short wheelbase. At 92 inches, it was 7.5 inches shorter than the already �

notably short McLaren M10a. To achieve such a short wheelbase, the driver was positioned �

farther forward than in almost any other formula car. �

�

Despite Mark Donohue's enthusiasm for the short wheelbase, many of Lola's customers�

didn't seem to like it. In terms of victories, it was demonstrably more successful than its �

predecessors: Ron Grable won two of 1970's first ten North American Formula 5000 races, and �

the T190 also picked up three wins in the (20 race) UK series. However, customer concerns �

about the short wheelbase were heard back at the factory. Some teams had trouble getting�

the suspension settings dialed-in for optimal handling. Before the 1970 season ended, Lola �

introduced a new longer-wheelbase model called the T192. It was basically the same design �

as the T190, except with the front wheels moved forward to extend the wheelbase by about �

ten inches. Mark Donohue drove a new T192 to win two of the three final races of the 1970 �

North American Formula 5000 season. �

�

Lola produced seventeen T190 racecars, followed by twelve T192 racecars.�

�

�

�

LOLA CARS LTD., YEOVIL ROAD, SLOUGH, BUCKS., ENGLAND.

�

Model: "TYPE-190", Chassis No.: "190/FI/8", Engine No.: (blank)

�

Please quote chassis number when ordering spares.

�

All design rights reserved. No reproduction without prior written permission.

�

Eric Haga's Lola T190: Chassis 190/FI/8

� �

Jim Matuska and Eric Haga had been campaigning cars together in regional races for�

several seasons. They started with a Porsche-powered Corvair for the 1967 season, �

and switched to a McLaren Mk3 for '68 and '69. Jim had the money to invest in top�

flight racecars, and Eric had the talent to drive them. With the McLaren, the two �

friends competed up and down the west coast, and entered in the Laguna Seca and �

Riverside Can-Am Series races. �

�

For 1970, they needed a newer car and they were initially undecided about what racing �

class they'd like to pursue. Ultimately, Jim Matuska decided that Formula 5000 was�

more appealing. He began making arrangements to set up a racing team with two cars, �

two drivers, and a sponsoring company. The team was organized as a division of Jim �

Matuska's and Weldon Andrews' successful aircraft components company. Larry Webb �

was hired on to be the team's crew chief. Larry brought in John Garrison to be the �

team's engine builder. Eric Haga would drive one new Lola T190, purchased by Jim �

Matuska. A second T190 was purchased and driven a friend and fellow Seattle area �

racer named Spence Stoddard. �

�

In November 1969, the new Competition Development division of Sealth Aero Marine wrote �

a purchase order to Charlie Hayes Racing Equipment, the West Coast sub-distributor (under Carl Haas) �

of Lola racecars, for two Lola T190 Formula 5000 racecars. The price was $15,500/each,�

including spares. �

�

| |

| SPECIFICATIONS SHEET | �

|

| LOLA T-190 FORMULA A | �

|

| CHASSIS: | �Aluminum alloy monocoque - bonded and riveted construction. � Torsional rigidity of 300,000 foot pounds per degree per foot. [sic]² � Weight: 70 pounds | �

| DIMENSIONS: | �Wheelbase 92"³ � Track 58" � Length 150" � Width 77" � Height (top of windscreen) 26" � Height (to of roll bar) 35" � Weight (including oil and water) 1,310 lbs. | �

| BODY: | �Fiberglass reinforced polyester resin. Nose cone and cockpit � surround. Alloy rear hub mounted wing and front canard fins (option). | �

| SUSPENSION: (FRONT) | �Independent. Double tubular wishbones and telescopic double- � acting shock absorbers with co-axial coil suspension springs. � Adjustable ride height. | �

| � | HUB CARRIER: Lola cast magnesium with "live" spindle. � Bearings of 160,000 pounds/square inch � nickel chrome molybdenum steel. | �

| � | WISHBONE PIVOTS: Rod end ball joints to inner enda and ball � joints in housing to outer end. All joints � high-quality Fabroid type. | �

| SUSPENSION: (REAR) | �Independent. Lower reversed wishbone and link. Upper link � and radius rod with telescopic double acting shock absorbers. � Co-axial coil suspension springs and adjustable ride height. | �

| � | HUB CARRIER: Lola cast magnesium with "live" spindle. Hub � bearings of 160,000 pounds/square inch nickel chrome � molybdenum steel, mounted in hub carrier splined for driveshaft yoke. � |

| � | WISHBONE & RADIUS ROD PIVOTS: as in front suspension. | �

| STEERING: | �Rack and pinion with 11" diameter leather covered steering � wheel. Column adjustable for length and angle. | �

| TRANSMISSION: | �Hewland DG-300 five speed and reverse. | �

| CLUTCH: | �Borg & Beck multi-plate (option) | �

| DRIVE SHAFTS: | �Lola design with Metalastic rubber "Doughnut". | �

| BRAKES: | �Girling 12" vented discs | �

| WHEELS: | �Front: 10.5" x 15"; Rear: 17" x 15" | �

| FUEL CELLS: | �30-gallon capacity with surge tank for pump pick-up. | �

| ENGINE: | �Chevrolet 302" with Lola dry sump and water pump conversion (option). � Small diameter Lola flywheel. Weber 48 IDA carburetors. Lucas � transistor or Bosch magneto ignition. Lucas fuel injection optional. | �

| COOLING SYSTEM: | �Brass fin and tube radiator. Water pipes separate and insulated. | �

| ELECTRICS: | �AC Delco or Lucas with Varley battery. | �

| INSTRUMENTS: | �Smiths tachometer, pressure, and temperature gauges. | �

| HOSES & FITTINGS: | �Aeroquip and A.N. | �

�

The two new cars would arrive in Seattle early in February 1970. The number eight car, �

190/FI/8 (as shown in this article) could have arrived earlier, except that Lola borrowed �

it for their display at The British Racing and Sports Car Club's "Racing Car Show"�

at Earl's Court in London. The number nine car was being constructed during the show, �

and it arrived in Seattle about a week after 190/FI/8. After the cars were received, �

Larry Webb took them completely apart and send all the suspension parts out to an FAA �

certified inspection facility to be checked for cracks and casting flaws. Then, he �

reassembled the car, replacing all the original hardware with MS NAS and AN (aircraft) �

grade fasteners. �

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

The two cars were supplied without engines, so the team purchased two Chevrolet racing �

engines from TRACO to be used at the first race (Riverside) which was coming up �

quickly. After that, John Garrison built the remainder of the team's engines. He used �

Chevrolet Z28 4-bolt main bearing blocks, bored 0.040" over. A standard stroke crankshaft�

was used, along with Carrillo rods and hot Isky camshafts. The engines produced about�

500hp on the shop's dyno. They normally built new engines for every race weekend. Based �

on the team's dyno testing, Weber downdraught carburetors produced almost 15hp less than �

the "Jackson Constant Flow Fuel Injection" system, so after the third race (Seattle) the �

team used fuel injection for the remainder of the season.�

�

| Eric Haga's results with 190/FI/8 in the 1970 L&M Continental (Formula 5000) Championship Series | |||||

| Venue | Date | Qualified | Finished | Notes | |

| 1 | Riverside | April 19 | 9 | 7 | |

| 2 | Edmonton | May 24 | 8 | DNF | Crash |

| 3 | Seattle | June 7 | 15 | 7 | |

| 4 | Laguna Seca | June 14 | 19 | 11 | |

| 5 | Sears Point | June 28 | 9 | DNF | Crash |

| 6 | Dallas | July 5 | 17 | 7 | |

| 7 | Road America | July 18 | 18 | DNF | Engine (valve) |

| 8 | Mt Tremblant | April 19 | 10 | 6 | |

| 9 | Donnybrooke | May 24 | 20 | 9 | |

| 10 | Lime Rock | June 7 | 13 | 9 | |

| 11 | Mosport | June 14 | 22 | DNS | Engine (valve) |

| 12 | Mid-Ohio | June 28 | 15 | DNF | Engine (fuel injection) |

| 13 | Sebring | July 5 | ? | DNS | Engine (magneto), on pace lap |

�

After the 1970 season, the number eight car was traded-in on a new T192, which Eric Haga �

drove throughout 1971. The T190 was re-bodied and driven by Bobby Unser in 1971's Questor �

Grand Prix. �

�

Eric Haga bought 190/FI/8 in 2008, and began restoring it for vintage racing. His ambition�

is that the restoration be as accurate as feasible. To that end, Eric in close consultation with�

Glyn Jones and Bob Marston. Glyn is the Heritage Coordinator at Lola Cars in England. Bob�

is retired now, but he was the principal designer of the T190. Bob Marston came to Lola �

after previously working at Cooper and Surtees. �

�

Except for tasks that require very specialized equipment or unusual skills, Eric is �

doing most of the restoration work himself, and it's a continuous project. His current focus�

is on fine tuning the suspension set-up, based on recommendations from Bob Marston as the �

original designer. Once the latest changes are tested and finalized, Eric plans to install �

a high-mounted rear wing, identical to what the car originally raced with. After that, the�

next planned change is to retrofit a Jackson constant flow fuel injection system. �

�

�

�

�

�

�

Features and Specifications (as of September 2009)

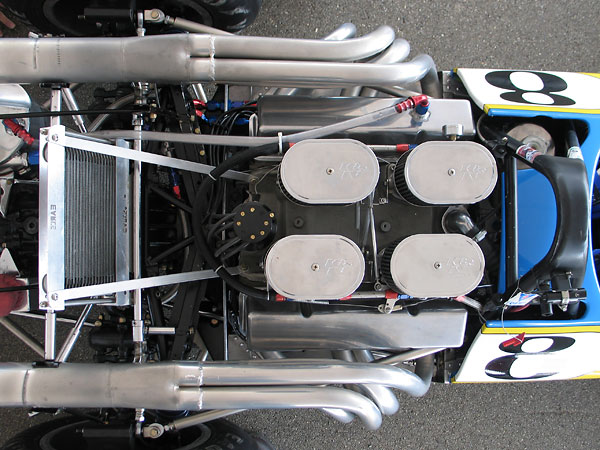

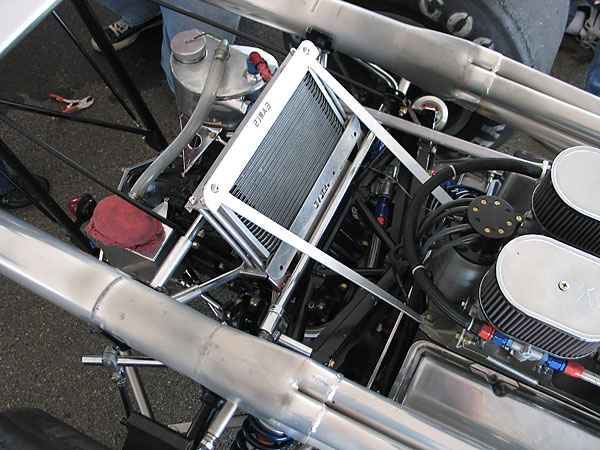

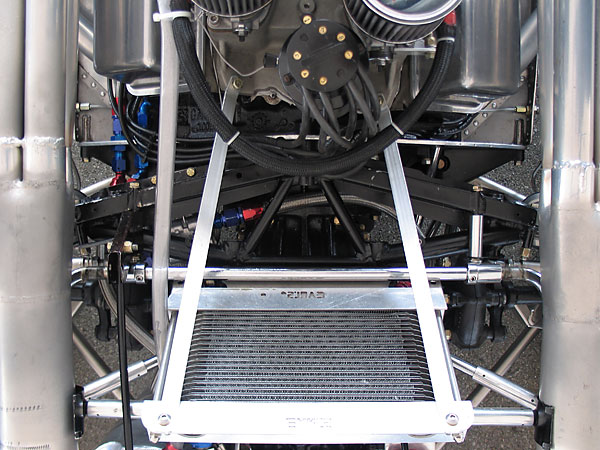

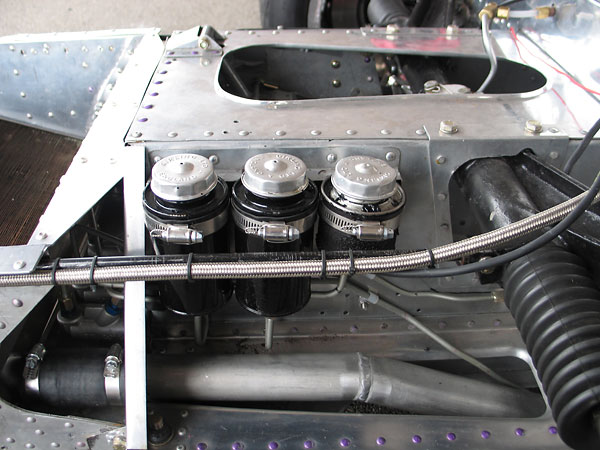

�| Engine: | �Chevrolet 302cid V8 engine, rebuilt by Larry Webb.�

Approximately 11.5:1 static compression ratio.�

Weber 48IDF downdraught carburetors.�

K&N air filters. �

Professional Products "PowerForce+Plus" harmonic balancer.�

Vertex magneto. �

Taylor Spiro Pro 8mm silicone insulated spark plug wires.�

ETC Incorporated high range 12V magneto rev limiter.�

Armstrong Race Engineering dry sump oil pan.�

Weaver Brothers oil pump.�

Earl's Performance Products engine oil cooler.�

Wix 51515R racing oil filter, remote mounted. | �

| Cooling: | �Serck brass dual-pass radiator (L2289-13). | �

| Exhaust: | �custom fabricated four-into-one headers, ceramic-coated. | �

| Transaxle: | �Hewland DG300 (-206) 5-speed with 9.31:1 ring and pinion.�

5.25" Metalastic donut-coupled halfshafts. | �

| Front Susp.: | �KONI 8212 coilover shock absorbers with Hypercoil springs. Adjustable anti-sway bar. | �

| Rear Susp.: | �KONI 8212 coilover shock absorbers with Hypercoil springs. Adjustable anti-sway bar. | �

| Brakes: | �(master) dual Girling master cylinders with remote reservoirs and bias bar. � (front) Girling calipers and 12" vented rotors. � (rear) Girling calipers and 12" vented rotors. | �

| Wheels/Tires: | �original Lola cast magnesium wheels (15"x10.5" front, 15"x17" rear). � Goodyear Eagle Sportscar Special (23.0x10.5x15 front, 27.0x14.0x15 rear). | �

| Electrical: | �Varley Redtop 30 battery. | �

| Instruments: | �(left to right) �

Stewart Warner voltmeter (10-16V),�

Stewart Warner oil temperature gauge (140-320V),�

Stewart Warner oil pressure gauge (5-100psi),�

Stack electronic tachometer (0-8000rpm),�

AutoMeter coolant temperature gauge (120-240F). | �

| Fuel System: | �Holley "red" fuel pump. Holley fuel pressure regulator. �

Professional Products "Powerflow" fuel filter.�

Mooneyes fuel pressure gauge (0-15psi, mounted at carburetors). | �

| Safety Eqmt: | �Willans six-point cam-lock safety harness. Quick release steering wheel hub.�

FireBottle 2.5lb Halon centralized fire suppression system. | �

| Racing Class: | �Formula 5000 | �

Engine Installation

��

�

The Chevrolet 302cid V8 engine has been rebuilt for vintage racing by Competition Development's

�

original Crew Chief, Larry Webb. Its build complies fully with the original 1970 rules.

�

�

Weber 48IDF downdraught carburetors with K&N air filters. In 1970, the Competition Development

�

team switched from Weber carburetors to a Jackson constant flow fuel injection system after just

�

three races. Eric Haga has now procured a Jackson system, and will install it during the 2010 season.

�

�

The Competition Development team had their own Heenan & Froud engine dynomometer. Among other

�

things, they used it for developing custom exhaust headers to suit their engines. The headers shown

�

here were custom fabricated to match the original 1970 Competition Development design.

�

�

Professional Products "PowerForce+Plus" harmonic balancer.

�

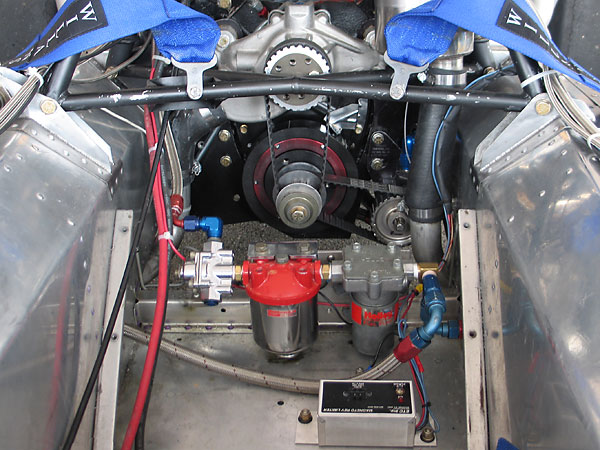

Holley fuel pressure regulator. Professional Products "Powerflow" fuel filter. Holley "red" fuel pump.

�

ETC Incorporated 12V magneto rev limiter.

�

�

This Weaver Brothers oil pump is just like the one used throughout 1970. Lola supplied their own dry

�

sump oil pan, but the car is currently using a (similar looking) Armstrong Race Engineering pan instead.

�

�

Vertex magneto. Taylor Spiro Pro 8mm silicone insulated spark plug wires.

�

�

Earl's Performance Products engine oil cooler. The original Lola T190 design had the oil cooler co-located

�

with the radiator in the nose-pod. That worked okay... until the team got to Dallas. For the rest of the

�

1970 season, the team used a rear mounted oil cooler and found it reduced oil temps by 10-15° F.

�

�

Rear bulkhead.

�

�

Wix 51515R racing oil filter, remote mounted.

�

�

Original aluminum oil reservoir tank, as supplied by Lola Cars.

�

�

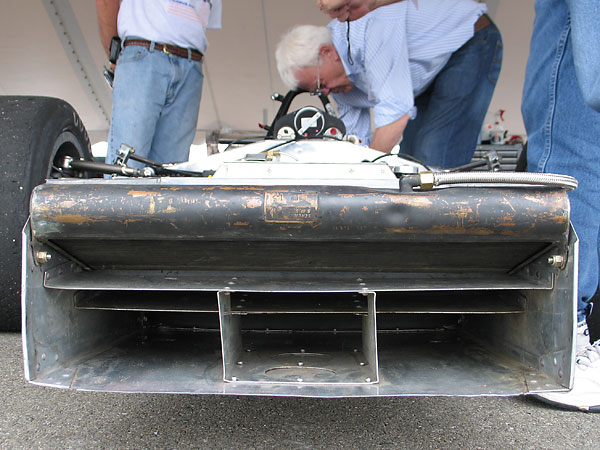

Serck all-brass dual-pass nose-mounted radiator. (It's marked part number L2289-13.)

�

�

Notice that dividers (both horizontal and vertical) distribute airflow over the whole radiator core.

�

�

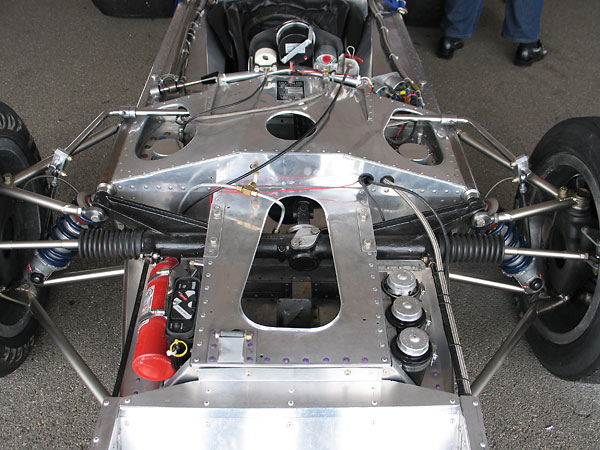

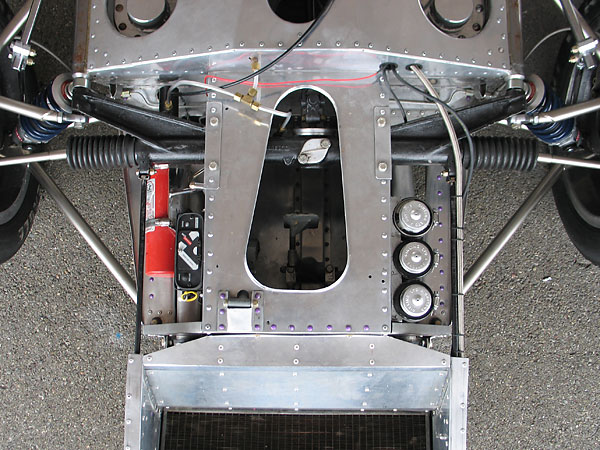

Front Suspension / Steering / Etc.

��

�

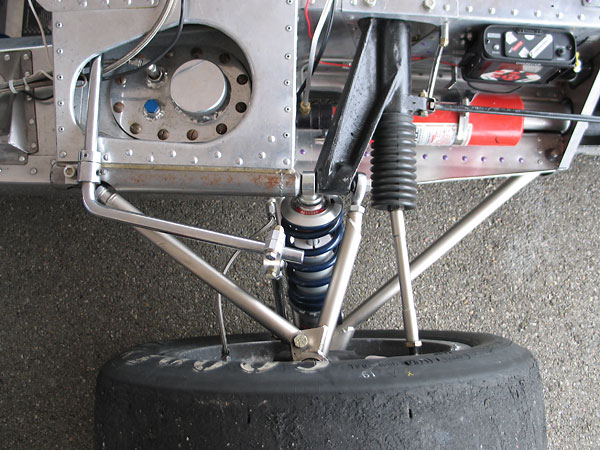

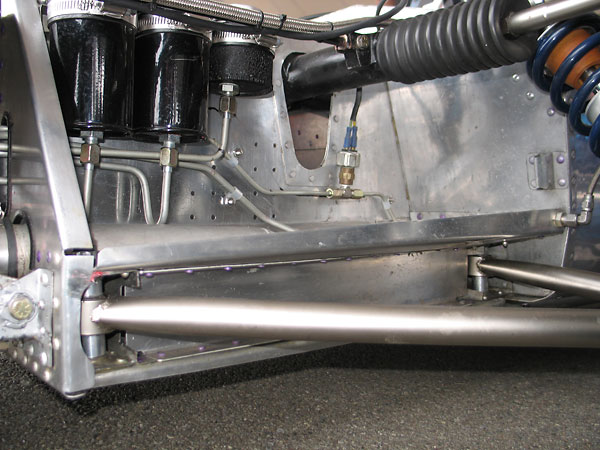

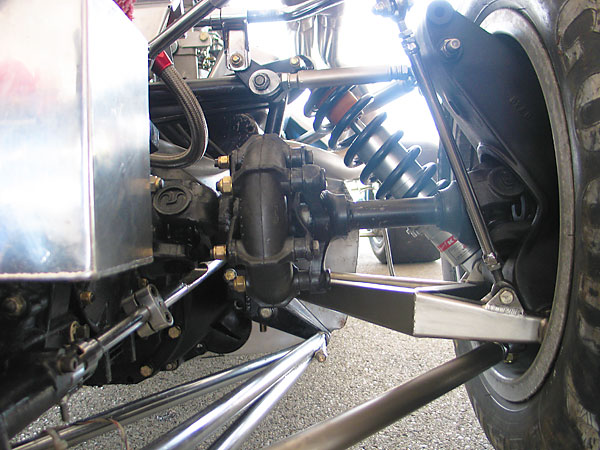

Left front suspension.

�

�

Lola supplied the T190 with Armstrong shock absorbers, but Competition Development took them off and

�

replaced them with lightweight, aluminum KONI 8212 double adjustable shocks (exactly like the ones shown

�

here) before the car was ever raced. They used KONI shock absorbers throughout the 1970 season.

�

�

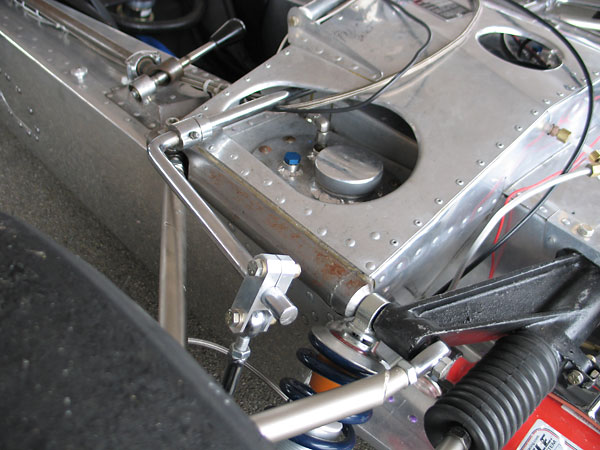

Steering link connections to Lola's magnesium uprights provide a wide range of bump steer adjustment.

�

That's necessary because there's no possibility of raising or lowering the steering rack.

�

�

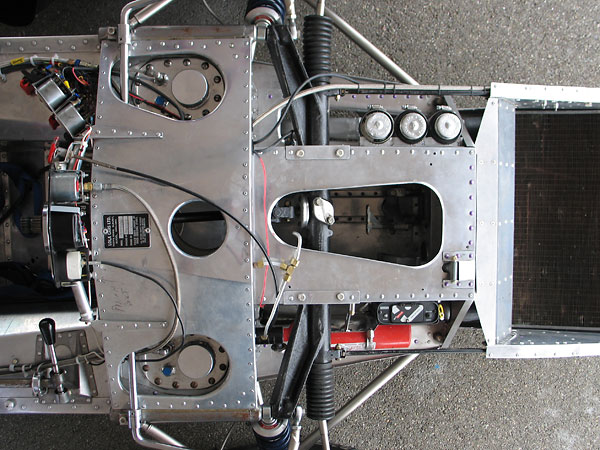

Besides showing the monocoque construction, this photo also illustrates just how

�

far forward the driver's feet are compared to the front wheels.

�

�

Lola designed an elaborate casting for the steering rack, and inexplicably placed the pinion off-center.

�

�

Refueling the Lola T190 requires removing the fiberglass bodywork. If the rubber fuel cell bladders

�

need service, they're also accessed through these holes in the monocoque tub.

�

�

Adjustable front anti-sway bar. The team tried lots of sway bar changes and adjustments over the season,

�

in an attempt to reduce understeer. They finally had things about perfect by Mid-Ohio. Mark Donohue was

�

there, and he crashed the Penske T192 during practice. Eric invited him to take out chassis 190/FI/8 for

�

a few test laps. Mark Donohue's only suggestion was to try a little toe-out. They tried it, and it worked!

�

�

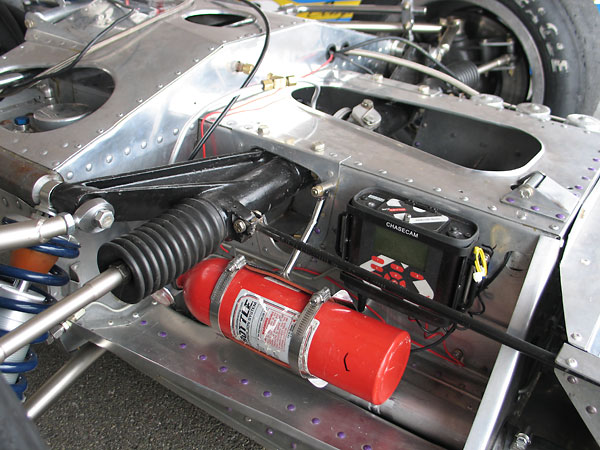

Two thin radius rods extend forward from bosses on the steering rack to support the cooling system.

�

�

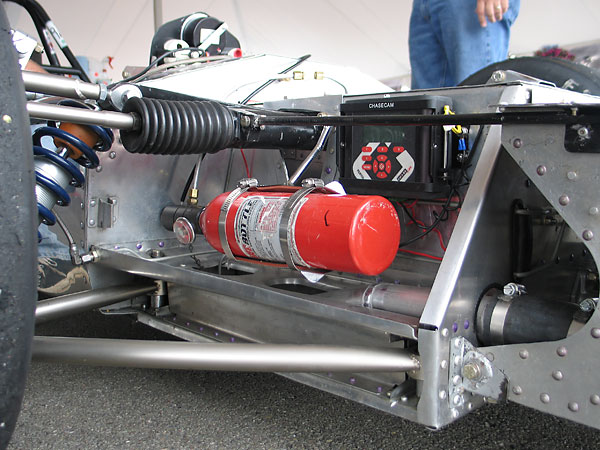

FireBottle 2.5lb Halon centralized fire suppression system.

�

�

The ChaseCam PDR-100 digital video system stores race footage on a CF memory card in MPEG format.

�

�

Inboard connections of the lower control arms can be adjusted for height, which means it's feasible to

�

adjust the amount of anti-dive characteristic in the front suspension to some extent. However, fine

�

adjustment of caster and camber must be completed at the upper control arms.

�

�

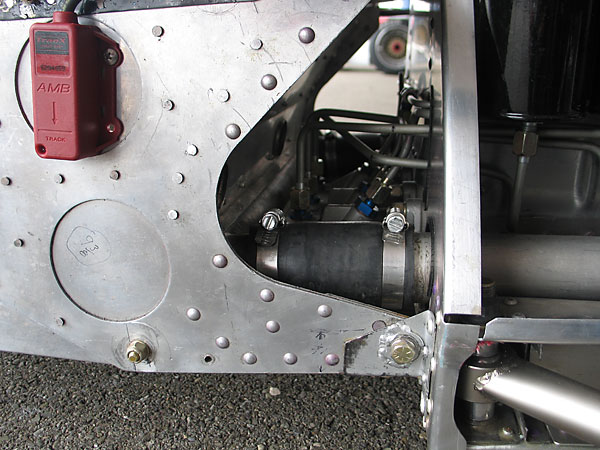

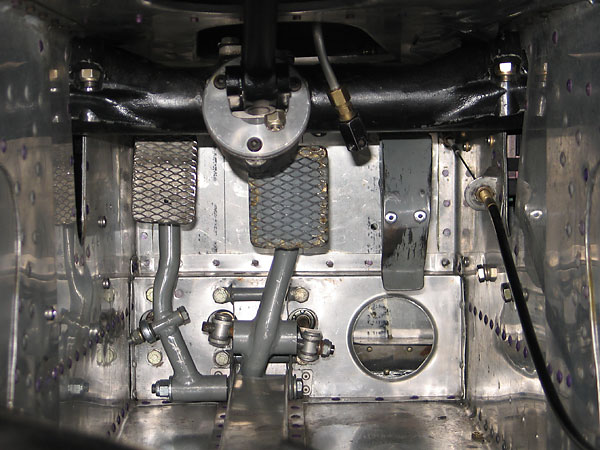

Dual Girling master cylinders with bias bar for the brake system.

�

Foreground: an AMB TranX 260DP transponder.

�

�

Girling steel reservoirs for the brake and clutch hydraulic systems.

�

�

A hydraulic pressure switch turns on the brake light.

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

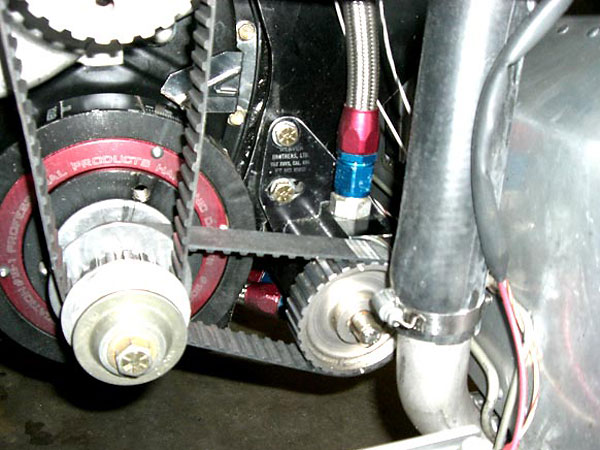

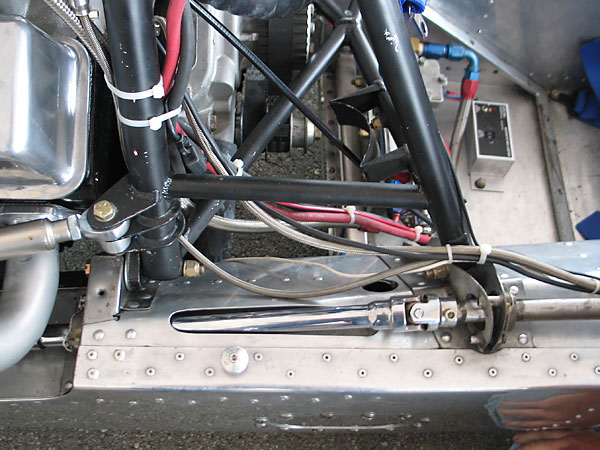

Rear Suspension / Transaxle / Etc.

��

�

"Hewland Engineering Limited, Maidenhead DG300-206"

�

�

The Hewland DG300 5-speed was a lot lighter than the LG600 six speed that was popular in F5000 one

�

year before. It had five forward speeds plus reverse, and all five gear ratios were easily replaceable, so

�

the Competition Development team selected ratios to suit the respective tracks they raced on.

�

�

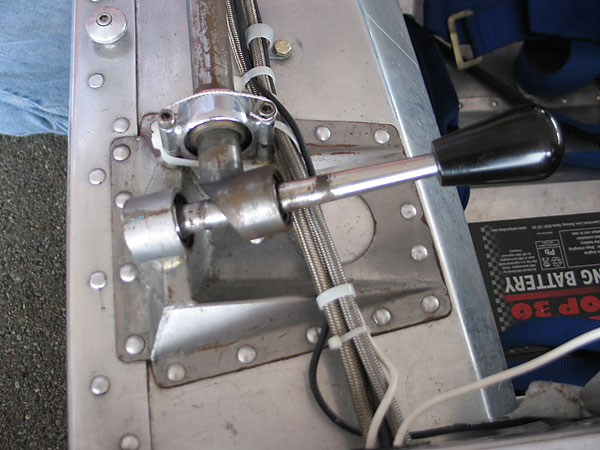

Here's a close-up of the gear selector.

�

�

The gear selector linkage is routed through a slot in the aluminum monocoque tub. Also shown:

�

the rear suspension's trailing links connect to tabs on the rollhoop / subframe.

�

�

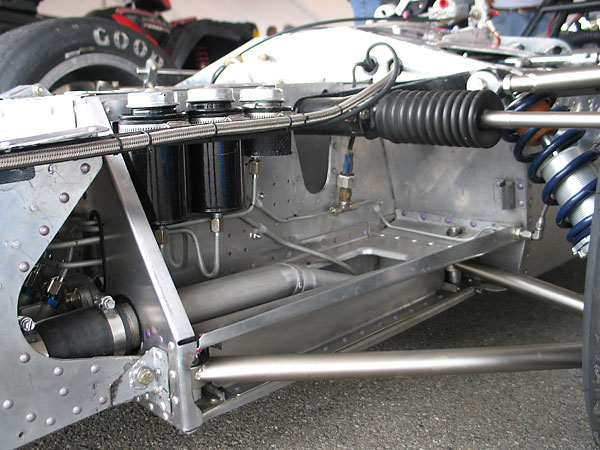

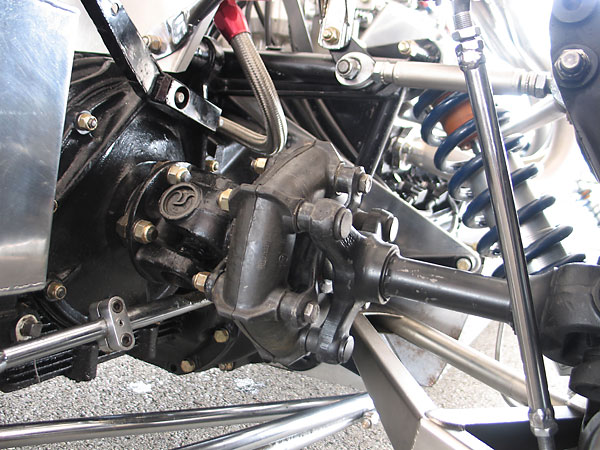

Whereas most formula cars have twin trailing links from the chassis back toward the rear wheel uprights,

�

the Lola T190 instead has its lower links behind the wheels. These links are loaded in compression under

�

braking and in tension under forward acceleration. Evidently the latter situation was given priority.

�

�

The lower radius rods aren't mounted at the same height as the lower control arms.

�

�

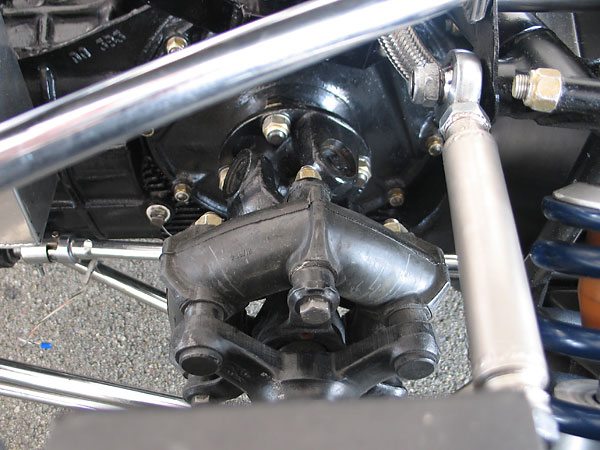

Metalastic rubber donuts absorb length variation at the halfshaft which occurs as the suspension works.

�

For this purpose, their advantage is they don't add friction or bind unpredictably. Smaller versions had

�

worked fine on thousands of low-power British cars for a decade, but Lola made a bold choice when they

�

put Metalastic donuts on 500+ hp racecars with sticky racing slicks. This size of Metalastic donuts

�

must work above rated specs, so their recommended service life is only a couple race weekends.

�

�

In 1970, Metalastic donuts were a relatively inexpensive and low-maintenance alternative to ball-splined

�

couplings or CV joints. Not anymore! According to Craig Taylor of Taylor Race Engineering, replacement

�

Metalastic donuts are still made in England by Dunlop, but the 5.25" size currently cost about $675/each.

�

The necessity for frequent replacement makes them a surprisingly costly maintenance item. For vintage

�

racing, Craig says it would be economical and safer to install modern halfshafts. Custom halfshafts with

�

108mm Lobro CV joints would require a one-time investment of about $3000. The conversion would be

�

easily and completely reversible.

�

�

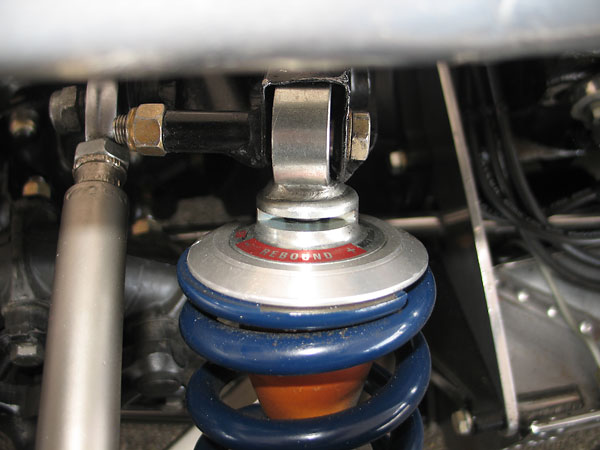

KONI 8212 shock absorbers are adjustable in both compression (at the bottom) and rebound (at the top).

�

�

The rebound dampening adjustment dial is recessed into this slot. A thin tool (e.g. 3/32" Allen wrench)

�

is inserted into the slot and swept from side to side to turn the dial and make the desired adjustment.

�

�

Interior

��

�

This is believed to be the original steering wheel that was supplied by Lola. In restoring the car to its

�

original appearance, an exact replacement wasn't found. After we took this photo, a similarly designed

�

Moto-Lita steering wheel was installed. As raced in 1970, the car didn't have a quick release steering

�

wheel hub, but a new spline-type hub has been installed for safety reasons.

�

�

Lola supplied the T190 with Smiths instruments, but they were replaced before it was ever raced.

�

The Competition Team preferred Stewart Warner gauges and Jones/Motorola mechanical tachometers.

�

Shown here: Stewart Warner voltmeter (10-16V) and oil temperature gauge (140-320V).

�

�

When we photographed the car it had a Stack electronic tachometer, which has recently been replaced

�

with an authentic Jones cable-driven tach. The Stewart Warner oil pressure gauge (5-100psi) shown here

�

remains in the car, but the AutoMeter water temperature gauge has recently been replaced too.

�

�

Gear selector, as viewed from the driver's seat.

�

�

�

Rather elaborately designed pedals. No dead-pedal was provided for the left foot.

�

�

Willans six-point cam-lock safety harness.

�

�

Exterior

��

�

Two generations of Formula 5000 cars: the car in the background is the Lola T332 that Brian Redman

�

drove to Formula 5000 Championship Victory in 1976. Eric's T190 looks resplendent and remarkably true

�

to how it looked while contesting every single event of the 1970 Formula 5000 season.

�

�

"Crew Chief: Larry Webb '69-'71"

�

Roy Dunn of Dunn Auto Graphics in Des Moines, Washington recreated the car's original graphics,

�

with modest and tasteful changes to suit the car's new career in vintage racing.

�

�

"Thanks Jim" - "Thanks Weldon"

�

Note: the front wings were used with end-plates early in the 1970 season, but not at the end.

�

�

At St.Jovite, Eric's teammate Spence Stoddard rolled his own T190 over. A new roll hoop was required to

�

repair that car. Lola had already changed over to producing a stronger and taller roll hoop design

�

for their new T192 model. It was a basically a bolt-on upgrade, so chassis 190/FI/8 was upgraded too.

�

A later owner replaced the T192 roll hoop. For the time being, the car is fitted with this T190 roll hoop.

�

�

From St.Jovite (a.k.a. Mt.Tremblant) until the end of the season, the rear wing was painted with an

�

additional sponsor's name: "Grand Prix Restaurant". This was a friendly little deal with Jack Byers,

�

who drove a neatly prepared blue Lola T190. No money was exchanged, but Byers put Competitions

�

Development stripes and logos on his T190. Incidentally, Jack Byers T190 wore the number 7.

�

�

Throughout most of the 1970 season, the car raced with a very high-mounted rear wing.

�

Special Canadian rules required a lower mounted wing for the Edmonton race.

�

�

Original Lola cast magnesium wheels (15"x10.5" front, 15"x17" rear).

�

�

Goodyear Eagle Sportscar Special tires (23.0x10.5x15 front, 27.0x14.0x15 rear).

�

�

We enjoyed watching Eric's beautiful Lola T190 at the 2009 U.S. Vintage Grand Prix of Watkins Glen

�

It's best lap that weekend was 2:13.658, for an average of 91.6mph over the challenging 3.4 mile circuit.

�

| Notes: | |||||||

| (1) | �

The quote is from Mark Donohue's autobiography, The Unfair Advantage. In it, Donohue �

explains that he only drove the Lola T190 in that one race because of a special arrangement�

with the car's owner, Carl Haas. The car was then sold to one of Carl Haas's customers.�

For much of 1970, Donohue would be busy racing in other series. That's the year he placed �

second in the Indianapolis 500, driving a Lola-Ford, He also actively campaigned an AMC �

Javelin in the NASCAR stock car series.�

� Just in time production: according to Lola records Mark Donohue's T190 was shipped from their � factory in England on December 12th, and Jo Bonnier's T190 was shipped on December 15th. � Both cars were supplied without engines.� � | ||||||

| (2) | �

We're completely certain the torsional rigidity figure quoted on the original specifications �

sheet from Charlie Hayes Racing Equipment is erroneous. As a practical matter, torsional�

rigidity is normally measured over a car's wheelbase. The appropriate unit of measure �

is "foot-pounds per degree". Mark Donohue recounted in The Unfair Advantage how �

the Penske race team checked the torsional rigidity of a Lola T330 chassis (circa 1973):�

� "I was hoping that the basic problem was too much flex in the chassis. When the next� car arrived we set it up on our surface plate, replaced the springs with solid bars,� and tested its torsional rigidity. Woody spent a week at it, anchoring one end, twisting� the other end with hydraulic jacks, and measuring the deflection with dial gauges. It� turned out to have a stiffness of about 4000 foot-pounds per degree, which ought to � be perfectly adequate for a race car. We could see a little bending in the middle,� though, so we added a couple of extra braces between the roll bar and cylinder heads." � � Bob Marston, Eric Broadley's Chief Engineer through most of the Formula 5000 era, � has informed us that Lola practice was slightly different. Lola measured chassis � stiffness by connecting directly to the chassis at the front and rear shock absorber � mounting points. A measurement of 4000 foot-pounds per degree is within the right� order of magnitude, although he would expect the T330 to be significantly stiffer� than the T190 because the T330 was a more sophisticated design. � � | ||||||

| (3) | �

Various wheelbase measurements have been published for the Lola T190. Although original �

sales literature (above) from Charlie Hayes Racing Equipment cited a wheelbase of 92", �

in the course of researching Mead Korwin's Lola T192 we have been in touch with former �

Lola Chief Engineer Bob Marston. Bob visited with Lola historian Glyn Jones, and �

reported back as follows: "When we checked the original T190 layouts, the wheelbase was �

definitely 88 inches and not any of the many other dimensions that I have seen quoted."�

� | ||||||

�

All photos shown here, except one, are from September 2009 when we viewed the car at The US Vintage Grand �

Prix at Watkins Glen. Photos by Curtis Jacobson and Don Moyer for BritishRaceCar.com, copyright 2010. �

All rights reserved. The one exception is the close-up photo of the Weaver Brothers oil pump, which �

was taken by Eric Haga and which is used by exclusive permission.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Bill Thumel '67 Lola T70 Mk3 | �

| �

Mead Korwin '71 Lola T192 | �

| �

Jim Stengel '73 McRae GM-1 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�