�

�

�

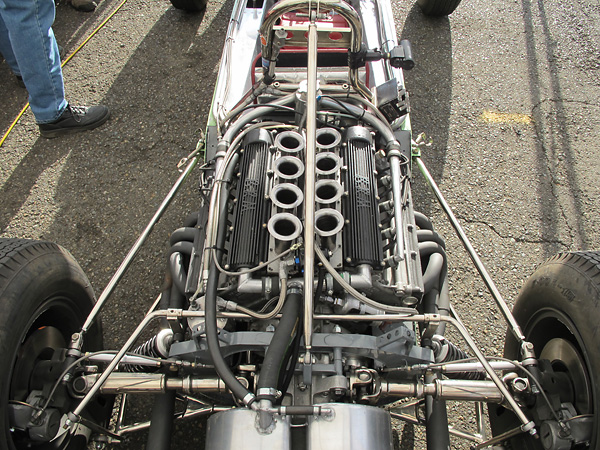

Kurt DelBene's 1964 B.R.P. (BRP-BRM) Grand Prix Race Car

� � Owner: Kurt DelBene� City: Redmond, Washington

� Chassis: BRP 64/2 replica

� Engine: BRM 1.5L V8

� Race prepared by: Byron Sanborn at Vintage Racing Motors�

�

The British Racing Partnership

��

After a Brands Hatch directors dinner meeting in November 1957, Stirling Moss' father Alfred and his manager�

Ken Gregory took an opportunity to talk shop. After many years of supporting Stirling's career, both men realized�

they'd soon have extra time on their hands because Stirling Moss had recently signed on to two premier works�

racing teams: Vanwall and Aston Martin. It occurred to the two men that they should establish their own racing�

team, as a partnership.�

�

Their idea was to purchase suitable cars and hire up-and-coming drivers. Perhaps Stirling would occasionally�

find time to drive for them between other commitments. It would be fun for all concerned. It might even�

make a little money. (The partners would be satisfied if it broke even.) These were sportsmen of the noblest�

type: plucky underdogs who occasionally punched well above their weight. Alfred Moss put up £2000�

and also offered his farm as a physical base. After just a couple months, Ken Gregory repaid £1000 pounds�

from entry fees, prize money and contengency fees (paid by fuel and tire suppliers, etc.). From then on they�

were equal partners. The new team was named British Racing Partnership.�

�

British Racing Partnership was active from 1958 through 1964. Over that period BRP entered 157 different�

cars in 275 different races, employing 32 different drivers including three world champions.�

�

BRP's first car was a Formula 2 Cooper, chassis number F2-10-58,�

with Climax FPF engine number 1041. Their first employee was their Chief Mechanic, Tony Robinson. Robinson�

had been with Stirling Moss and Ken Gregory since 1953. Stuart Lewis-Evans was the first of BRP's many drivers,�

and with him they were off to a promising start: a fine fourth place finish in the Lavant Cup. �

�

One of BRP's big challenges was that drivers tended to jump from car to car so frequently. (Like Stirling Moss,�

Lewis-Evans also drove for Vanwall and Aston Martin.) This affected scheduling and planning, sometimes in�

dramatic ways. Lewis-Evans died tragically before the end of the 1958 season of burns incurred after an accident�

in his Vanwall. BRP employed a number of outstanding drivers in those early years, only to lose them too soon. �

�

BRP entered Stirling Moss in two Grand Prix races during the 1959 season. The story behind those entries is an�

interesting digression: BRM was trying to recruit Stirling Moss to drive their P25 model car, but he wasn't comfortable�

with BRM's team management. Alfred Moss negotiated a deal where Stirling would drive a loaned BRM P25 but it�

would wear BRP livery and would be maintained and entered by BRP. Stirling Moss ended up suffering a�

disqualification at the French Grand Prix, but recovered to place second two weeks later at the British Grand Prix.�

A schedule conflict prevented Moss from driving the P25 at Berlin in the German Grand Prix, so Hans Herrmann�

drove it instead. Herrmann had a spectacular accident. (The BRM P25 had its rear brake installed on its propshaft�

where it was subject to an acute vibration, with an unfortunate result being that it severed a brake pipe and had a�

total brake failure.) The car was written off, which ended the agreement between BRM and BRP. The BRM P25�

was an exception to a rule though; generally, BRP was a loyal Cooper Car Company customer.�

�

1960 was arguably the most important year of British Racing Partnership history because it was the year that�

Yeoman Credit Finance bankrolled BRP's efforts. "Yeoman Credit Racing" was the first totally sponsor-funded�

team in the history of motor racing. No team had ever before been sponsored by an outside company.�

BRP was given a sum of £40,000 just to buy their equipment plus £20,000/year to operate the�

team. With that much invested, it seemed they could compete on an even footing with any of the works teams.�

There would still be great difficulties. The team suffered two tragic driver fatalities that year: Harry Schell at�

Silverstone and Chris Bristow at Spa. Yeoman Credit's sponsorship of BRP wasn't renewed. �

�

In 1961 BRP signed a major sponsorship agreement with United Dominions Trust, who among various holdings�

owned Laystall Engineering, the principle supplier of crankshafts to the British automotive and aviation industries.�

The name "BRP" was still used for the management company, but the team's race entries were filled out "UDT-Laystall�

Racing."�

�

The generous UDT sponsorship deal seemed threatening to BRP's rivals, who frankly feared a bidding war for top�

drivers. The works teams seemed to feel especially threatened, but they had a way to level things back out. They could�

decline to sell BRP competitive cars. So it was that when Ken Gregory sat down with his very close and long time�

friend Charlie Cooper to discuss BRP's needs for the new Grand Prix season, he was told Cooper's supply of�

gearboxes were already committed, and therefore Cooper wouldn't be able to supply BRP a single complete�

Formula One racecar until July. (Other teams, including Reg Parnell's, were already scheduled to be served first.)�

�

Ken Gregory did what he had to do; he turned to Colin Chapman for a supply of Lotus racecars. The timing�

is interesting. Chapman had just signed up driver Jim Clark, so perhaps he didn't feel BRP was such a danger�

after all. Chapman sold BRP a mixed bag of cars, and they fielded a diverse mix of drivers. The purchase included�

three Lotus 18 (Formula One) racecars,�

three Lotus 19s, and one Lotus Elite. (By swapping between Climax four cylinder engines, BRP was able to race�

the Lotus 19s in four different classes.) In 1961 Grand Prix championship races UDT-Laystall was represented by�

four different drivers from four nations. They had hoped that Cliff Allison would drive throughout the whole season,�

but he had a bad accident, and suitable replacement drivers had various schedule conflicts. Lucien Bianchi,�

Masten Gregory, and Henry Taylor also drove for BRP in 1961 championship series Formula One races.�

(Juan Manuel Bordeu practiced at the French Grand Prix, but didn't start the race.)�

Additionally, Stirling Moss, Jo Bonnier and Carl Hammarlund drove for BRP in non-championship Formula�

One races. Then there were the lesser formulae. It was a busy year with only occasional and moderate success.�

�

For 1962 the UDT-Laystall team was more focused. They committed to fielding just two Grand Prix drivers and to�

keeping each of them in a specific car for the entire Grand Prix season. (By and large this worked out, although BRP�

was obliged to use back-up cars occasionally.) UDT-Laystall's star driver would be Innes Ireland, who had recently�

been dropped hard by Colin Chapman. Their second car would be driven by American driver Masten Gregory.�

UDT-Laystall procured two new Lotus 24s for the season. Ireland's Lotus 24 was powered by a Coventry�

Climax V8, whereas Gregory's Lotus 24 car was powered by the newly introduced BRM V8.�

�

Despite focus, the 1962 season went horribly for UDT-Laystall. It started on the wrong foot, with Innes Ireland having�

an accident at Zandvoort in the first of nine championship races. He would fail to finish four others due to breakdowns.�

There were other highs and lows. Ireland arrived too late to qualify at London's Formula One (non-championship)�

Crystal Palace Trophy Race and was thus obliged to start at the back of the grid, yet he sling-shotted past the entire�

field to grab a magnificent victory. Ireland also demonstrated his quickness by qualifying third fastest at the British�

Grand Prix. (Ireland lost first and second gear in the lap from the pits to the starting line and thus drove the whole�

British Grand Prix without low gears. He finished the race fourteen laps behind his personal rival, Jim Clark.)�

Ireland's best 1962 championship series result was in the season's final race, the South African Grand Prix, where�

he finished fifth but not before being lapped by 1962 champion Graham Hill. At the end of 1962, UDT withdrew�

their sponsorship.�

�

�

�

BRP-BRM

�

British Racing Partnership built their own racecars for the 1963 and 1964 Grand Prix seasons.

�

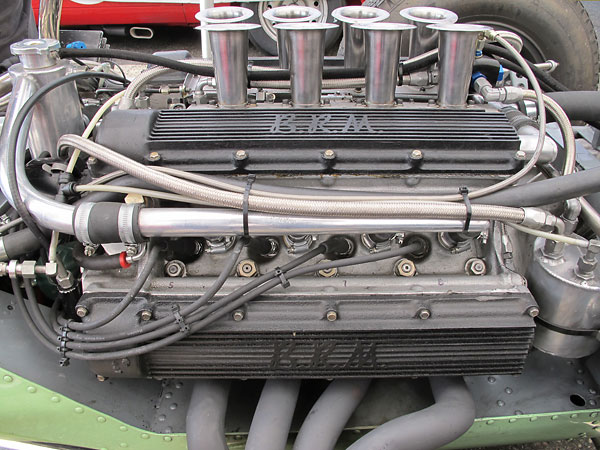

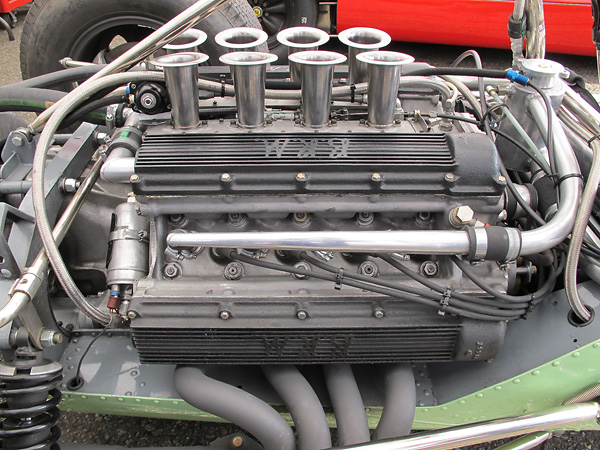

For these cars, BRP used British Racing Motors brand engines. BRM's logo is a stylized compass.

�

Please support the sponsoring companies who make www.BritishRaceCar.com possible, including:

� �

�

�

�

�

Origin of the BRP-BRM Design: a racecar for the monocoque era.

��

BRM, Cooper and Lotus had obvious conflicts of interest. Each of these companies sold racecars to outside�

customers and then raced against them with their own works racing teams. Inevitably, this situation led to difficulties.�

At the start of the 1962 season, Colin Chapman aggressively promoted the Lotus 24 as a brand new�

design, without telling his customers it would be obsolete by the second round of the Grand Prix championship.�

The Lotus 24 debuted at the non-championship1962 Pau Grand Prix on April 23rd, and the Lotus 25 debuted�

at the Dutch Grand Prix on May 20. When the Lotus works team appeared with their new monocoque chassis,�

Lotus customers such as BRP were understandably peeved. Whereas the Lotus 24's steel spaceframe weighed�

about 130 pounds, the Lotus 25's aluminum tub only weighed about 70 pounds. Furthermore, the Lotus 25�

was reckoned to be much stiffer. Lotus claimed 1000lbft/degree torsional stiffness rising to ~2400lbft/degree with�

engine installed. Adding insult to injury, Chapman was very clear that the Lotus 25 wouldn't be available to outside�

customers - not even for the following season!�

�

When the Lotus 25 arrived, many people assumed tube-frame racecars were racing toward a dead end.�

Indeed, the revolution was coming, but not as quickly as they feared. Brabham won the 1966 and 1967�

championships with a steel spaceframe chassis. But BRP strongly believed they needed a monocoque chassis�

to stay in the race against Lotus, and none was available for purchase, so they drafted their Chief Mechanic�

Tony Robinson into the role of designer. His brief was simple: "Just like Lotus, take Lotus 24 front and�

rear suspension parts off the shelf and mount them on a dual-pontoon aluminum tub." (BRP already had a�

large stock of Lotus 24 spares. If they hadn't, they would have fabricated their own suspension components�

as in fact they did for the following season.)�

�

Who was this new designer? As a young man, Tony Robinson started a mechanic's career at a London�

Ford dealership and then served 18 months compulsory service in the RAF. His next job was maintaining trucks�

for a glass merchant, but in actuality he spent most of his time working on trials and rally cars for the company's�

principal. In late 1952, Robinson answered a classified ad in Autocar magazine to be a mechanic for Ray Martin�

Motors. Stirling Moss' Chief Mechanic, Alf Francis, conducted the interview. Ray Martin Motors were building a�

Cooper-Alta for Moss to drive for the 1953 Grand Prix season. A falling out between Alf Francis and Ray Martin�

Motors resulted in the project being removed to John Cooper's shop. Robinson moved with the project,�

becoming an employee - not of Cooper Cars - but instead of Stirling Moss Limited and reporting to�

Ken Gregory. Robinson would continue working with Gregory for another dozen years.�

�

Robinson summarized how the original BRP-BRM concept came together in a Vintage Racecar magazine interview�

(Nov./Dec. 2007): "I thought it was time we looked at building our own car. If we were to do that it would have�

to be a monocoque car, not tubular. We had to keep up with the new trend. A meeting was convened at Papa Moss'�

dental surgery, in the Strand. [Actualy on Chandos Place, behind St Martin-in-the-Fields church.] I'm not a pen and�

paper man; just practical. I'm a builder. During the course of the season I kept a look out at how the Lotus 25 was�

constructed. I began to realize it wasn't too difficult to do. I made up a small section, a cross-section of the tub�

about 10 inches wide, and took it along to the meeting. �

�

"We could use the suspension parts of the 24's; we had plenty of spares. We could simulate a monocoque chassis,�

in the style of the 25. It was to use a known factor rather than a direct copy. The suspension, wheels, and other parts�

were all known to us, too. I didn't make any detailed drawings of the car, just a few sketches to help me. My�

advantage was having a Lotus 24. I designed our first BRP around that, but using monocoque technology.�

I used the 24 shape to help with pick-up points for suspension and the like, the front bulkhead and driver positions.�

�

"To manufacture the tub, I needed a good bunch of blokes around me, who were pretty good. I had Jim Chapman�

and George Woodward (both of whom went to Lola after the demise of BRP), Peter Downing (who went on to�

power-boat racing), Stan Collier (who went on to RALT), an apprentice named Bruce McIntosh (later responsible�

for much of McLaren's 'F1' road car, the Mercedes SLR McLaren, etc., before joining Gordon Murray as Head of�

Engineering and he additionally serves as FIA's Technical Representative for the GP2 racing series.), and Rod Gueran�

(who had previously served in the RAF as an airframe fitter). A good bunch of lads!"�

�

When the BRP-BRM debuted at Spa in the 1963 Belgian Grand Prix, its appearance was very noteworthy�

because after the Lotus 25 it was only the second monocoque chassis of the modern era. Right out of the box,�

Innes Ireland qualified seventh quickest, one place ahead of Jim Clark in the Lotus 25 (with a time of 3:56.9 vs. 3:57.1).�

�

�

�

In lieu of a tubular steel frame, BRP created an elaborate fabrication of thin NS4-spec aluminum panels.

�

�

IMPORTANT ANNOUNCEMENT

�

BritishRaceCar.com will have to cut back plans for continued growth if we can't find more financial support.

�

If you like what you've found here, and you want to see more, please click here and follow the instructions.

�

Readers like you keep BritishRaceCar.com online and growing through voluntary financial contributions.

�

BRP-BRM Formula One Results

��

Charismatic and popular British driver Innes Ireland drove BRP-built racecars in five of ten 1963 Grand Prix�

championship races and seven of ten 1964 championship races, plus seven non-championship�

Formula One races. Throughout the 1963 season, Ireland's BRP teammate Jim Hall drove an older�

car: a BRM powered Lotus 24, but for 1964 Jim Hall moved on and was replaced by Trevor Taylor. Taylor�

was provided a second-generation BRP-BRP racecar, and he drove it in seven of the 1964 season's ten�

championship events plus four non-championship races.�

�

BRP's 1963 Grand Prix Championship Results ¹

�| Race / Venue | Date | Winning Car | Ireland's Result (in BRP-BRM) | Jim Hall's Result (in Lotus 24) | |

| 1 | Monaco Grand Prix | May 26 | BRM | (Lotus) retired, accident, Q5 | retired, gearbox, Q13 |

| 2 | Belgian Grand Prix (Spa) | June 9 | Lotus-Climax | retired, gearbox, Q7 | retired, accident, Q12 |

| 3 | Dutch Grand Prix (Zandvoort) | June 23 | Lotus-Climax | 4th, Q7 | 8th, Q18 |

| 4 | French Grand Prix (Reims) | June 30 | Lotus-Climax | 9th, Q9 | 11th, Q18 |

| 5 | British Grand Prix (Silverstone) | July 20 | Lotus-Climax | retired, ignition, Q11 | 6th, Q13 |

| 6 | German Grand Prix (Nürb.) | Aug.4 | Ferrari | retired, accident (1st lap), Q11 | 5th, Q16 |

| 7 | Italian Grand Prix (Monza) | Sept.8 | Lotus-Climax | 4th (engine failed at end) | 8th, Q17 |

| 8 | U.S. Grand Prix (Watkins Glen) | Oct.6 | BRM | withdrawn (injured) | 10th, Q10 |

| 9 | Mexican Grand Prix (Mex.City) | Oct.27 | Lotus-Climax | withdrawn (injured) | 8th, Q15 |

| 10 | South African Grand Prix (P.G.) | Dec.28 | Lotus-Climax | didn't participate | didn't participate |

| Final: | Lotus (Clark) | 9th in points | 13th in points |

�

BRP's 1964 Grand Prix Championship Results ²

�| Race / Venue | Date | Winning Car | Innes Ireland's Results | Trevor Taylor's Results | |

| 1 | Monaco Grand Prix | May 10 | BRM | DNS (accident in practice) | retired, fuel leak, Q14 |

| 2 | Dutch Grand Prix (Zandvoort) | May 24 | Lotus-Climax | didn't participate | didn't participate |

| 3 | Belgian Grand Prix (Spa) | June 14 | Lotus-Climax | 10th, Q16 | 7th, Q12 |

| 4 | French Grand Prix (Rouen) | June 24 | Lotus-Climax | retired, accident, Q11 | retired, accident, Q12 |

| 5 | British Grand Prix (Brands) | July 11 | Lotus-Climax | 10th, Q10 | (Lotus 24) retired, unwell, Q18 |

| 6 | German Grand Prix (Nürb.) | Aug.2 | Ferrari | didn't participate | didn't participate |

| 7 | Austrian Grand Prix (Zeltweg) | Aug.23 | Ferrari | 5th, Q11 | retired, suspension, Q16 |

| 8 | Italian Grand Prix (Monza) | Sept.6 | Ferrari | 5th, Q13 | DNQ |

| 9 | U.S. Grand Prix (Watkins Glen) | Oct.4 | BRM | retired, gearbox, Q10 | 6th, Q15 |

| 10 | Mexican Grand Prix (Mex.City) | Oct.24 | Brabham-Climax | 12th, Q16 | retired, overheating, Q18 |

| Final: | Ferrari (Surtees) | 14th in points | tied for 19th in points |

�

�

Podium finishes eluded the BRP team through the two championship seasons, but Innes Ireland did drive�

his BRP-BRM to victory in the opening race of the 1964 season, the Daily Mirror Trophy at Snetterton.³�

Except for Ferrari, all the top teams and most of the top drivers participated. Driving through heavy sleet and�

in snow, Ireland came from seventeenth place to take the checkered flag in a race that was flagged early due�

to inclement weather. Only thirty-five of the scheduled fifty laps were run. �

�

�

�

�

�

Sorting Out the Various B.R.P. Formula One Racecars

��

The BRP team designed and constructed exactly three Formula One racecars, and all were built for the team's�

own use. No additional or spare monocoque tubs were built by BRP. The first car of the type, chassis number�

63/1, was built specifically for Innes Ireland to drive through the 1963 Formula One season. 63/1 featured a�

BRM B56 V8 engine and a Colloti Type 32 five speed gearbox, although BRP later updated it to a BRM�

six speed gearbox.�

�

BRP 63/1 still exists, sort of. After BRP was done with it, 63/1 passd to Alf Francis who in mid-1966 was�

employed by Scuderia Serenissima to develop a one-off Formula One entry which was to be powered by�

one of Giovanni Volpi's V8 engines. BRP 63/1's monocoque tub was used, though highly modified with�

entirely retrograde suspensions at both front and rear. Inboard front suspension was replaced with outboard.�

Independent rear suspension was replaced with a deDion set-up. Testing went badly. The resulting car�

unsuccessfully contested one Austrian hillclimb in 1970 before being retired. Photos and additional�

documentation of 63/1's reincarnation can be found here.�

�

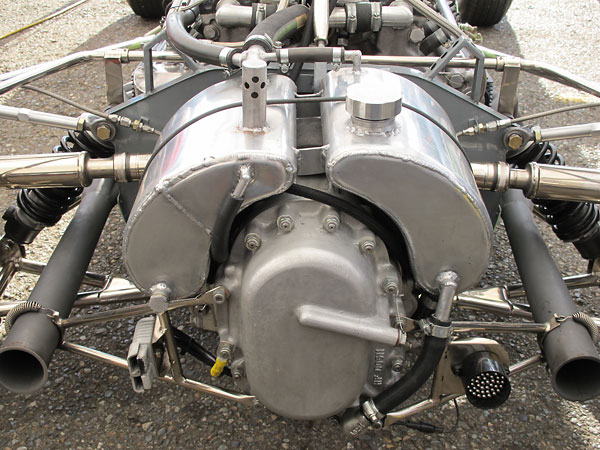

For the 1964 Formula One season, the team built two additional BRP racecars: 64/2 was built for Innes Ireland�

and 64/3 built for Trevor Taylor. Both 64/2 and 64/3 were built with BRM B56 engines, mated to BRM's excellent�

six speed transaxles. �

�

�

�

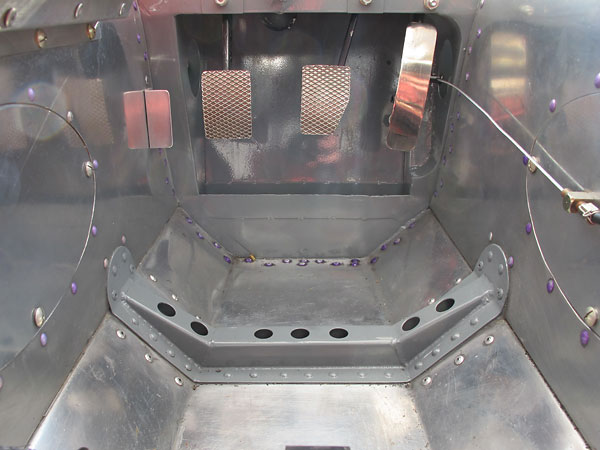

The three BRP-BRM racecars were built around distinctly different NS4 aluminum monocoque tubs. All

�

three featured a dual pontoon ("bathtub") layout with various thicknesses of aluminum. The pontoons

�

were generally D-shaped in cross section and about 12" tall by 6" wide, but their shape and dimensions

�

through the cockpit area varied in detail. 63/1 was 11.0" wide at the pedals, it tapered out to 16.50" wide

�

at the instrument panel, then it continued rearward with parallel sides along the driver's torso. 63/1's inner

�

panels were 16 gage and its outer skin was 18 gage. 64/2 and 64/3 were tailored to fit Innes Ireland and

�

Trevor Taylor respectively. Both of these cars were 9.5" wide at the pedals, tapered out to 13.5" wide, but

�

to suit Trevor Taylor's wider hips, 64/3 was widened approximately 1" on either side with inset pocketed

�

panels. To reduce weight on the 1964 cars, inner panels were 18 gage and the outer skin was 19 gage.

�

�

How else did 64/2 and 64/3 differ from the original BRP-BRM (63/1)? Firstly, Tony Robinson redesigned�

front and rear suspensions to utilize lower, wider wheels and tires. Except for the four suspension uprights,�

Lotus 24 spare parts were no longer suitable, instead BRP specially designed and fabricated their own parts�

or else at least procured parts from other sources. They were now a constructor in their own right. A detailed�

look at the BRP design can be found below.�

�

After its original Grand Prix career, BRP chassis number 64/2 passed to John Willment Automobiles, who�

entered it in one Formula One race in the 1966 season. This was of course after Formula One rules changed�

to permit larger engines, so Tony Robinson was hired to install a Climax 3.0L V8 engine. At the International�

Gold Cup, held on 17 September 1966 at Oulton Park, John Campbell-Jones qualified tenth, but was black�

flagged due to an oil leak. �

�

BRP 64/2 reappeared again in 1969 after conversion to Formula 5000 specification with a Ford 4798cc V8�

engine and a Colotti-Francis gearbox. Amateur British driver Kaye Griffiths entered his BRP in the final six�

rounds of the inaugural British Formula 5000 season, then transported the car to New Zealand where he�

entered the first three rounds of the 1970 Tasman Series.4�

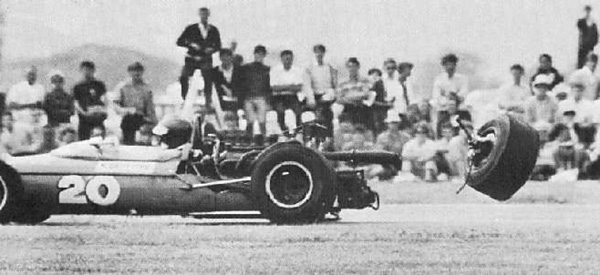

After a broken rear upright caused a wheel to come off during qualifying for the car's third Tasman Series�

appearance, Griffiths sold 64/2 to local New Zealand driver Peter Hughes, who repaired it and entered one�

additional Tasman Series race before putting the car into storage, where it suffered severely from neglect.�

�

In 1985 the well known New Zealand fabricator and constructor Ferris de Joux, assisted by ex-McLaren mechanic�

Peter Bruin (of Goodwood Engineering in Auckland), restored 64/2 using the few remaining original parts�

found by a friend of Ferris on the back of a truck heading for the scrapyard. Ferris explained: "When I got the�

original tub it was just $150 worth of rubbish with the nose cone broken off a few inches ahead of the front bulkhead,�

no roll over bar, pedals, radiator, or brackets, or engine mounts. We pulled it apart and used it for patterns. The centre�

bulkhead, radius rod mounts, dashboard and frame, mounts for the rear leg of the bottom front wishbone, outer skins�

for the front section of the tub, and the front suspension rockers were the only usable parts. Peter made the front bulkhead.�

It was very expensive. I cut out the rear bulkhead and Peter welded it." Later, Ferris wrote: "The engine (block, at least)�

was one of BRP's as was the gearbox (62/9)5, dash panel, outer skin, center�

bulkhead, dash frame, front rockers, and suspension brackets. I built the inner skin, engine cover, and the front half of�

the nose cone."�

�

While building a new monocoque tub and incorporating in it a few reusable components mentioned above�

(e.g. center bulkhead, outer skins for the front section, etc.), Ferris de Joux also built an additional tub to the same�

pattern. This second tub was originally assembled with a Ford 'Kent' four cylinder engine and a Hewland transaxle, but�

they've been removed. Allen McGregor of Scotland bought the two de Joux racecars (i.e. the restored 64/2 and�

the replica made from it) and campaigned them in the UK. Rob Fowler of Hall&Hall was hired to rebuild the�

replica to a far more representative specification (e.g. BRM 1.5L engine, stroked to 2.0L, and BRM six speed transaxle,�

as seen here). Microsoft President Kurt DelBene subsequently bought the cars. The more-original Innes Ireland�

1964 season car (chassis 64/2) retains a 1.5L BRM engine, and makes occasional racing appearances in England�

and Europe. Its livery is identical to the replica shown here, except that it wears racing number 9 instead of number 41.�

This replica is kept in Redmond, Washington and makes occasional appearances at North American events.�

�

What happened to the third of the three original BRP-BRM racecars? Stirling Moss Auto Racing Team retained 64/3 and�

entered it in the 1966 South African Grand Prix with Richie Ginther driving. Ginther spun out the car and was�

broadsided by Jo Bonnier (in a Rob Walker Lotus-Climax.) The resulting damage meant BRP 64/3's racing days were�

over, but it was returned to England and sold to Jim Russell. Russell had a contract to supply cars for John�

Frankenheimer's classic movie "Grand Prix" (circa 1966). For that use, 64/3 was modified by former Lotus racing�

mechanic Ted Woodley. According to some reports, it was fitted with an early (non crossflow) Ford Kent engine�

and a Hewland transaxle. There are conflicting reports about 64/3's precise role(s) in the movie. After filming,�

whatever remained of 64/3 was scrapped. �

�

Features and Specifications (as currently presented)

�| Engine: | �BRM "B56" 1.5L V8 engine, stroked to 2.0L�

Dual overhead camshafts (i.e. two per cylinder bank), gear driven.�

Single plane crankshaft.�

Lucas mechanical fuel injection (Mk1 8-cylinder).�

Lucas 3SC transistorized electronic ignition (disable. �

A late model Lucas ignition box is hidden under the seat, with a rev limiter.)�

Belden spark plug wires.�

Dry sump lubrication system. | �

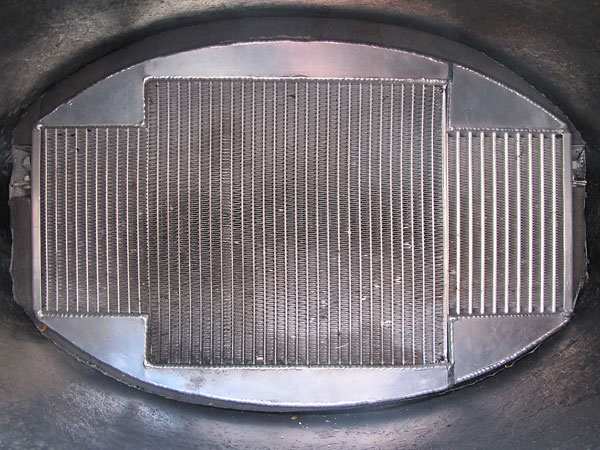

| Cooling: | �aluminum radiator with integral (side-by-side) engine oil cooler. | �

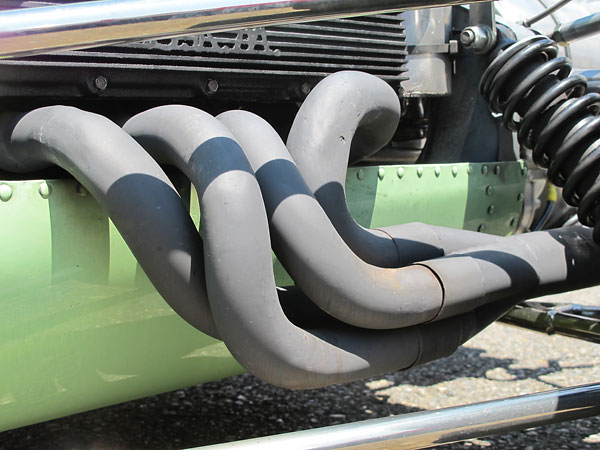

| Exhaust: | �bespoke sand-bent four-into-one headers. | �

| Transaxle: | �BRM 6-speed transmission, without reverse. � Clutch type limited slip differential.� Roller bearing / universal jointed half shafts. | �

| Front Susp.: | �dual wishbone front suspension.�

Coilover KONI model 8212 double adjustable shock absorbers actuated through (upper) rocker arms.�

Lotus magnesium front uprights (part number 1988).�

Non-adjustable anti-sway bar.�

Track = 52.5". | �

| Rear Susp.: | �inverted lower wishbones, single top links, and twin radius arms.�

Lotus Type 18 (F1) through 21 magnesium rear uprights (part number 8318-2.)�

Coilover KONI model 8212 double adjustable shock absorbers.�

Non-adjustable anti-sway bar.�

Track = 55.0". (Wheelbase = 91.0".) | �

| Brakes: | �(master) dual Girling master cylinders with adjustable bias bar. � (front) Girling AR brake calipers and 10.5" solid rotors. � (rear) Girling AR brake calipers and 9.5" solid rotors. | �

| Wheels/Tires: | �reproduction Lotus "wobbly web" style six-lug front wheels.�

H&H four-lug rear wheels.�

Dunlop Racing 5.50-L13 CR65 MkII (front) and 7.00-L15 CR65 (rear) tires. | �

| Electrical: | �alternator.�

Odyssey Extreme Racing 30 battery (part number 9750M6746, AGM, 20.0lb, 450CCA).�

Ark Racing lightweight gear reduction starter motor. | �

| Instruments: | �(left to right)�

Racetech dual fuel pressure (0-160psi) and coolant temperature (30-120C) gauge,�

Smiths tachometer (0-12,500rpm),�

and Racetech dual oil pressure (0-160psi) and oil temperature gauge (30-120C).�

| �

| Fuel System: | �two new fuel bags, with combined capacity of 14 gallon.�

Facet low pressure electric fuel pump.�

Bosch high pressure electric fuel pump.�

FueLab 535-series fuel pressure regulator.�

Lucas fuel injection metering unit. | �

| Safety Eqmt: | �Willans six point cam-lock safety harness.�

RaceTech quick release steering wheel hub.�

Lifeline Zero 2000 centralized fire suppression system. | �

| Racing Class: | �1.5L Formula One (except with a Tasman Series spec engine.�

(In other words, a longer stroke crankshaft has been installed�

to increase displacement to ~2.0L.) | �

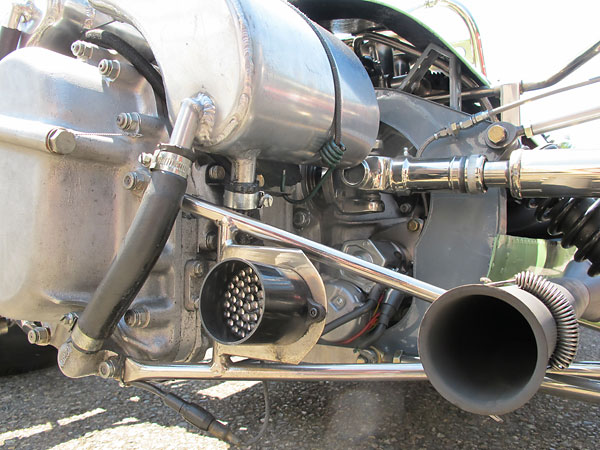

Engine Installation

��

�

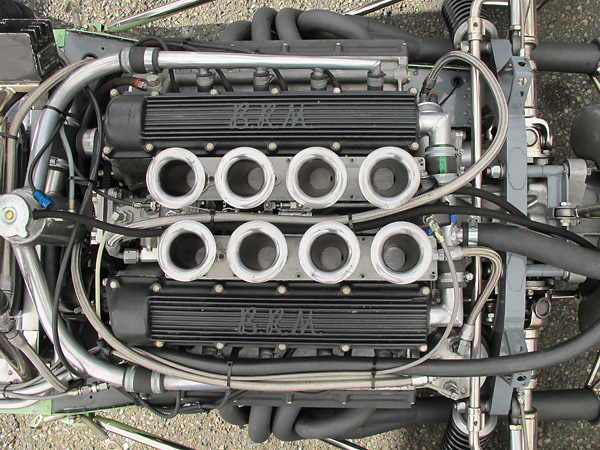

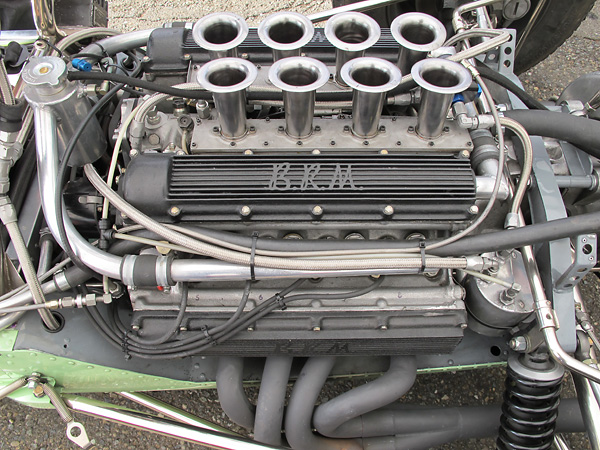

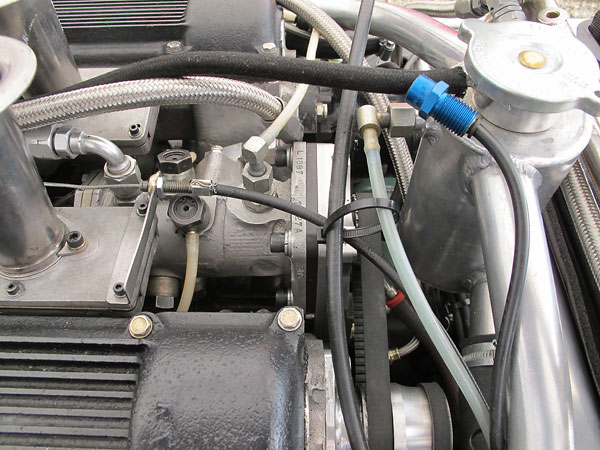

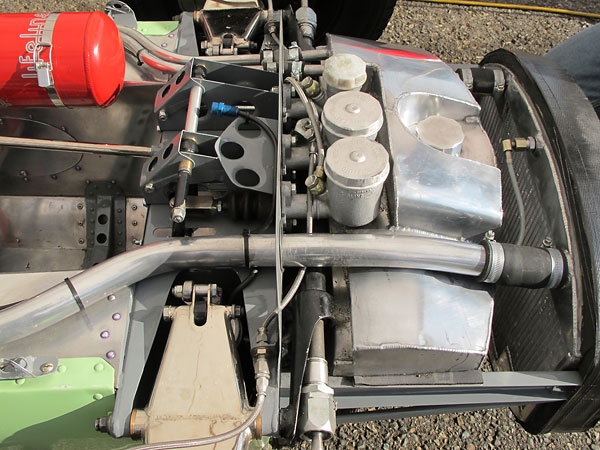

The BRM "B56" 1.5L V8 engine was first introduced in October 1961.

�

�

In Formula One trim, its 68.5mm bore and 50.5mm stroke combined for a displacement of 1498cc.

�

The BRM B56 engine was rated 205hp at 11,000rpm. Of course, performance varied by installation.

�

�

The BRM engine's camshafts were gear driven. Rival Climax V8s used chain-driven camshafts.

�

�

The BRM engine also featured a single plane crank. Climax started with dual-plane cranks on their V8s,

�

but switched and used single plane cranks from ~September 1964. One major advantage of a dual-plane

�

crankshaft is that its better balanced, which can improve engine durability and reduce bearing wear.

�

Single plane cranks use a different firing order, and that firing order simplifies exhaust optimization.

�

�

Hand-crafted, sand-bent, four-into-one exhaust headers.

�

�

BRM offered various differently configured cylinder heads for these engines. For example, the BRM

�

works team chose center-exhaust cylinder heads for their 1964 BRM P261 racecars. In other words,

�

their exhaust ports exited into the engine's valley, and intake ports were routed between camshafts.

�

Tony Robinson: "BRM team personel were very helpful to work with, but Innes, Masten, and

�

Trevor often complained that our engines lacked the performance of the works cars."

�

�

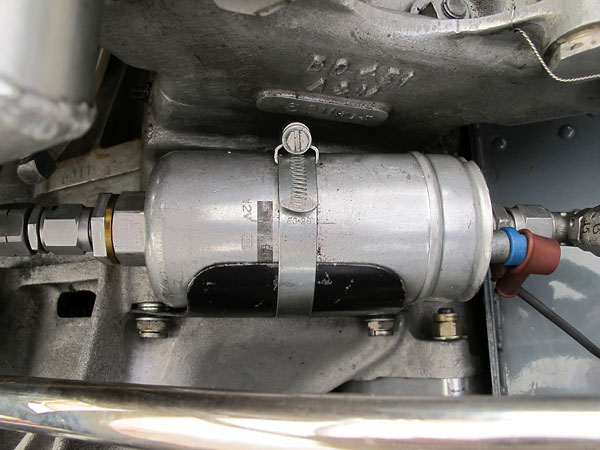

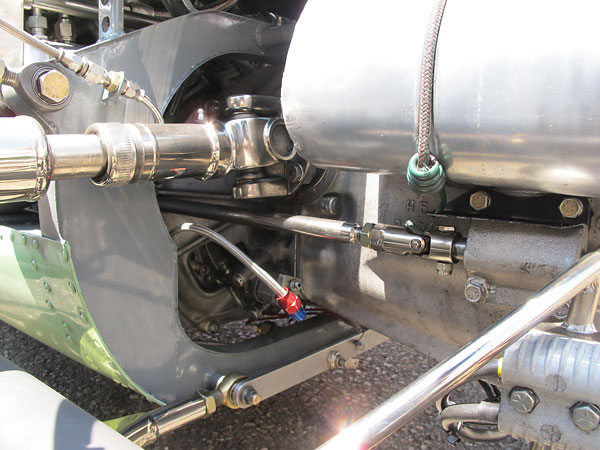

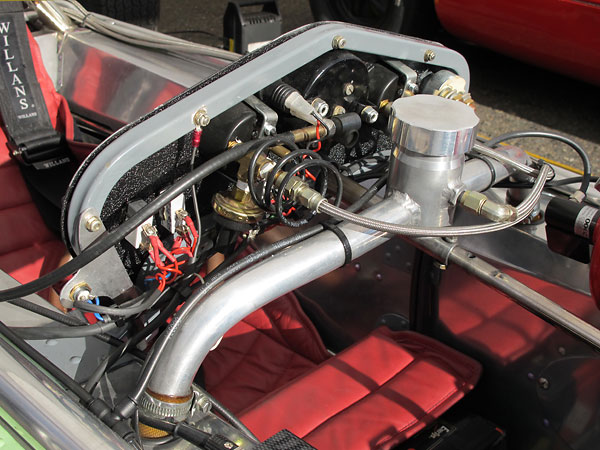

A Facet (Bendix type) low pressure electric fuel pump fills an intermediary tank.

�

�

This is the intermediary "make up" fuel tank.

�

�

This is a relatively modern Bosch high-pressure electric fuel pump, but it is installed in

�

the same position as the original Lucas fuel pump. The Lucas fuel pumps used by BRP

�

and some of their contemporaries were commonly referred to as "bombs." That's a

�

pretty clear hint why they're better suited for car museums than for vintage racing.

�

�

The Lucas pumps were tall, and on the BRP-BRM their size necessitated a hole right

�

through the top of the engine cover. The hole is missing on this car, but does exist

�

on the sister car. These BRP-BRMs have never used engine-driven fuel pumps.

�

�

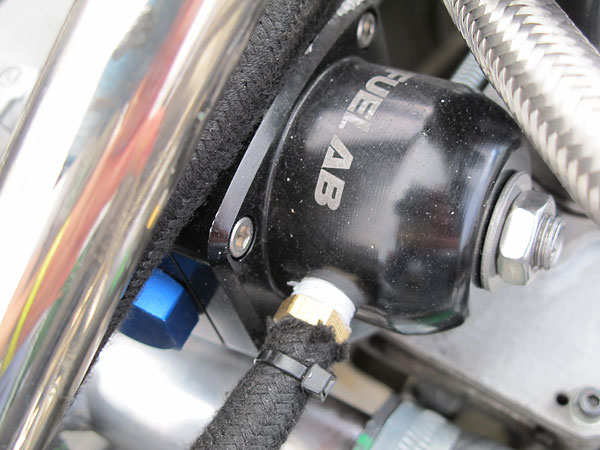

Modern FueLab 535-series adjustable fuel pressure regulator (in situ).

�

�

The high pressure fuel pump can deliver as much as 120 psi whereas the Lucas reciprocating

�

shuttle fuel metering and distribution system requires about 100psi. This adjustable

�

fuel pressure regulator restricts the high end, for more consistent performance.

�

�

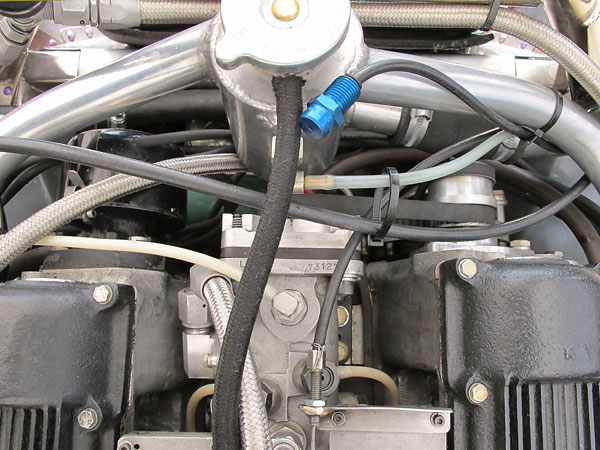

This is the period correct Lucas mechanical fuel injection metering unit. BRP could easily

�

compare carburetion and fuel injection in 1963 because they ran carbs on Jim Hall's Lotus-BRM

�

through mid season. Hall reported a big torque improvement after upgrading to fuel injection.

�

�

This Lucas metering unit is stamped: L1897 73127A 5175.

�

�

Fuel is injected through simple jets, mounted just downstream of the throttle slides.

�

�

The Lucas transistorized (electronic) ignition system was introduced simultaneously on the BRM V8 and

�

also on the rival Coventry Climax V8. BRP mounted their Lucas transistorized ignition modules outside

�

where airflow would help keep them cool. The Lotus team mounted theirs in the V of the Climax engine,

�

vulnerable to failure due to overheating.

�

�

Lucas Transistor Spark Unit / Model 3SC, Serial No. 48004D, Date Code: 4-65 / Made in England.

�

The Lucas ignition system provided a tremendous high RPM performance improvement over any

�

breaker point based system and it was also more effective than the magneto ignition systems

�

available at the time. The issue is one of precision: for best performance, spark plugs must fire at

�

exactly the right time relative to the compression cycle, and without variation between cylinders.

�

�

The trigger mechanism employed four magnetic pole pieces mounted on a camshaft-driven flywheel.

�

It's a simple system: without any sort of "advance" mechanism as would be required for a street car.

�

In other words, spark plugs were timed to fire at 33 degrees before maximum compression (i.e. piston

�

"top dead center" position) - always - without consideration of engine RPM or load. This was suitable

�

for engines that typically ran at 11,000rpm whenever they were on track. At less than 6000rpm, the

�

engines certainly didn't run well, and they were a bear to start or drive through the paddock. For this

�

reason, for vintage racing the original electronics are actually disconnected and a more modern

�

electronic ignition module has been hooked-up underneath the driver's backrest.

�

�

Ark Racing lightweight gear reduction starter motor.

�

�

Aluminum radiator with integral oil cooler. (In this view, the oil cooler is on the righthand side.)

�

�

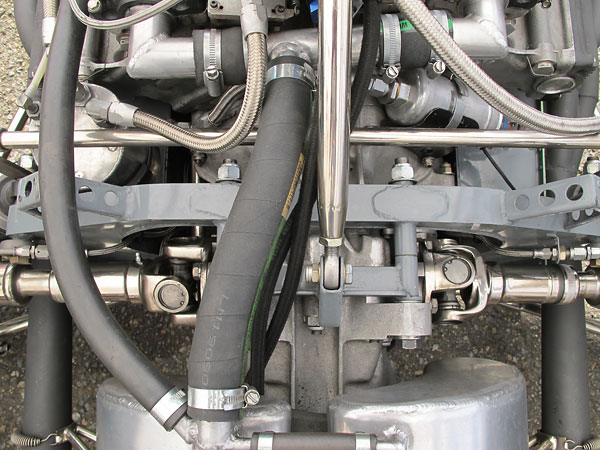

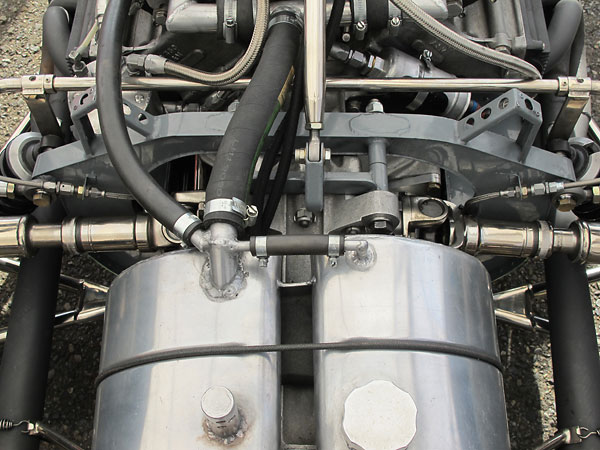

Coolant and oil return lines route underneath the chassis rather than through it.

�

�

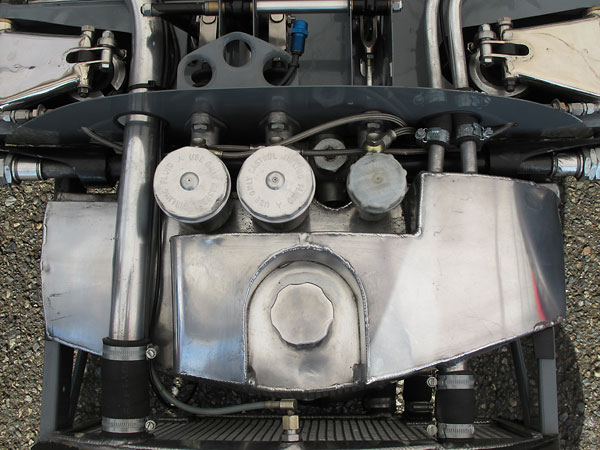

The engine is dry sumped, and its oil is stored in this large aluminum tank..

�

�

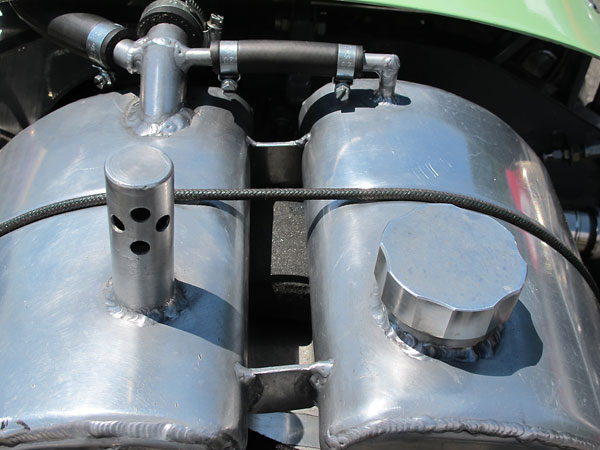

Left: crankcase breather/overflow tank. Right: oil reservoir for the transaxle, which is dry sumped.

�

�

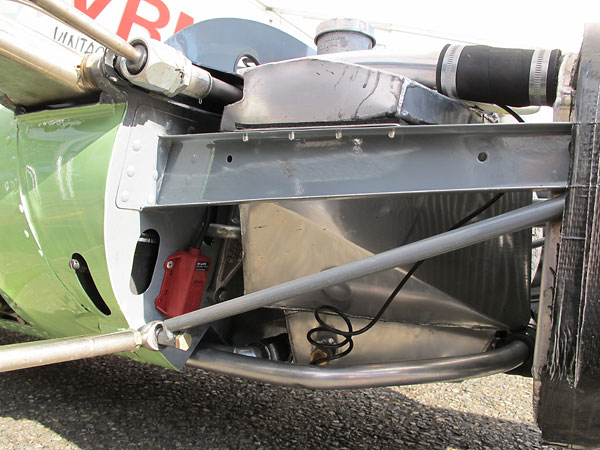

No rule required 1.5L Formula One cars to have a reverse gear, so the BRM transmission didn't have one.

�

It did have an early limited slip differential, although not a very good one by modern standards.

�

�

A rain light is required for vintage racing. This one features light emitting diodes.

�

�

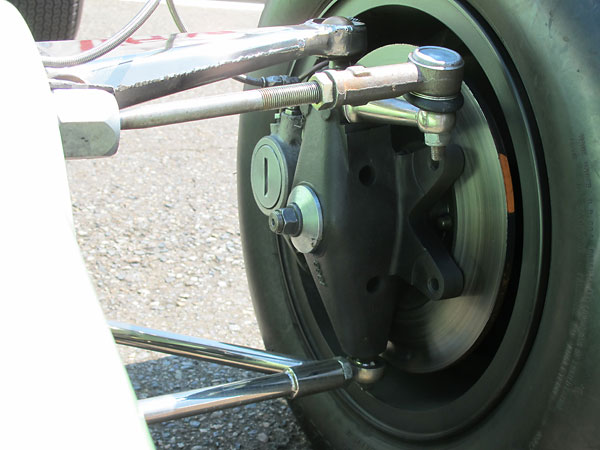

Front Suspension

��

�

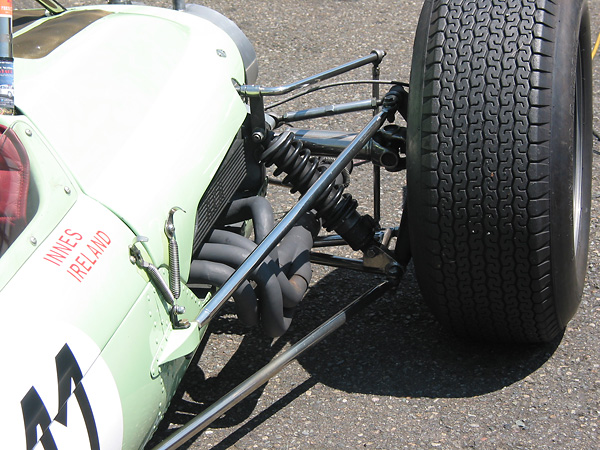

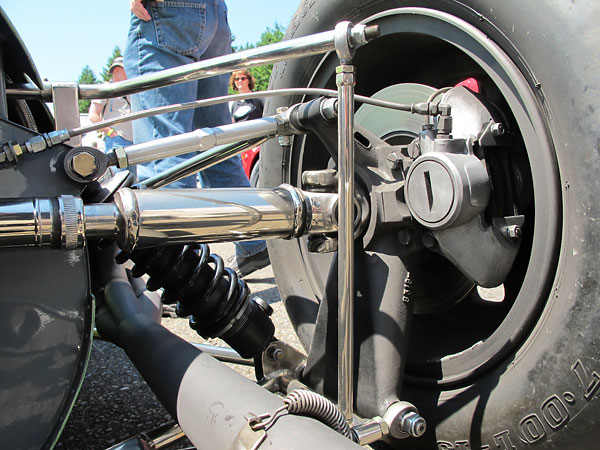

BRP initially carried over the familiar Lotus 24 front suspension to their own chassis. Then, BRP

�

worked to develop the car to suit wider and lower wheel and tire sizes as they became available.

�

�

Dunlop was the dominant supplier of Formula One tires through this car's era, and they continuously

�

improved their product. Compound and manufacturing changes improved grip and durability, while

�

sidewall height was coming down and tread width was getting wider. The L-section tires this car wears

�

for vintage racing hold it back from dramatically quicker lap times it could achieve with different tires.

�

�

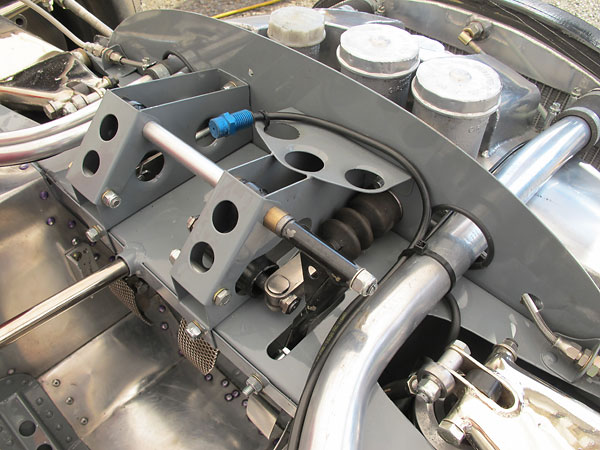

Inboard front suspension and front brakes tucked neatly into wheel cavities: Formula One designers

�

hadn't yet begun to seek aerodynamic downforce, but by 1963 they were quite good at streamlining.

�

�

Shock absorbers, springs, and the anti-sway bar are all actuated by rocker arms.

�

�

Lotus Elektron (magnesium alloy) front uprights, part number 1988.

�

�

Girling AR brake caliper and solid 10.5" rotor.

�

�

This early bathtub-style monocoque chassis could have been stiffer if its designers had taken simple

�

steps to brace across the large openings of its top, but it must have seemed incredibly stout in its day.

�

�

BRP didn't make their own steering racks. Instead, they used a Lotus rack on the first racecar (63/1)

�

and BRM steering racks on the last two (64/2 and 64/3).

�

�

The front anti-sway bar is non-adjustable, difficult to swap out, and impossible to see in this photo.

�

However, you can see the Heim joint and part of the link which connect it to the righthand rocker arm.

�

�

Girling brake and clutch master cylinders with integral reservoirs.

�

�

A lot of fabrication work went into elimination of flexing at the pedals and master cylinder mountings.

�

�

The red plastic device at left is a transponder, which is part of a modern timing/scoring system.

�

To the left of that are two holes in the tub through which shock adjustments can just barely be made.

�

Below the transponder, we see one of two V-section longitudinal channels for routing plumbing.

�

This is also the best photo we have of the structure that supports the radiator and oil reservoir.

�

�

Dunlop center-lock wheels were on BRP-BRM 63/1 when it arrived at Spa for its first race in 1963 but

�

were swapped out with Lotus wobbly web magnesium wheels for the race, and from then on BRP

�

used Lotus wheels through 1963. (15x6.0 at the front and 15x7.0 at the rear.)

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

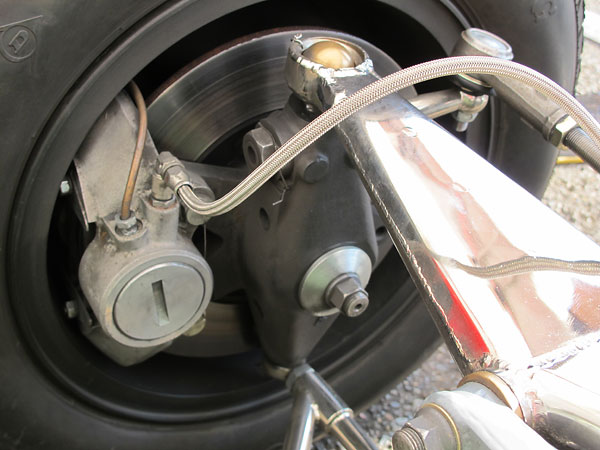

Rear Suspension

��

�

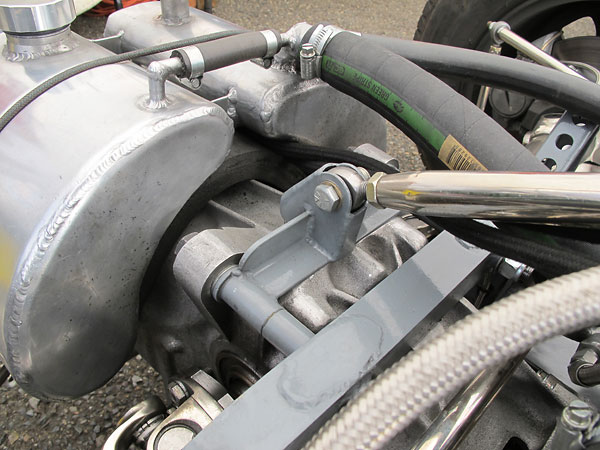

Inverted lower wishbones, single top links, and twin radius arms.

�

�

These were small cars. Rear track was just 55.0" and wheelbase was only 91.0".

�

�

On the Lotus 24, rear shock absorbers had been mounted behind the halfshafts. On the Lotus 25

�

and the BRP-BRM, the rear shock absorbers are located forward of the halfshafts.

�

�

On the BRP, the BRM engine block is a stressed member.

�

It contributes significantly to chassis strength and stiffness.

�

�

Safety wire, because things could get ugly if this bolt came loose.

�

�

Roller bearings in the half shafts accomodate plunge.

�

�

Non-adjustable rear anti-sway bar.

�

�

Rear bulkhead, shifter linkage, and clutch slave cylinder details. Notice that someone has added

�

an aluminum bar between the lower control arm mounts. This is a sensible and elegant design

�

refinement, but it doesn't appear in any old photographs of the car we've studied.

�

�

Lotus Type 18 through 21 magnesium rear uprights, part number 8318-2.

�

�

Coilover KONI model 8212 double adjustable shock absorber (not original).

�

�

Girling aluminum racing brake caliper. This is the AR size. Girling made larger versions called

�

BR and CR respectively. They also made a somewhat smaller version which was called NR.

�

�

Temperature indicating paint on the edge of the brake rotor changes color when it gets hot.

�

�

The rearward roll hoop brace is modern, and pains have been taken to make its installation "reversible."

�

�

A detailed look at the rear bulkhead, from above.

�

�

The most important technical change BRP made for 1964 was the switch to wider, smaller diameter

�

tires. This wasn't a simple swap because suspension geometry had to be altered significantly, and

�

of course new wheels were required. BRP used Lotus six-stud 13x7.0 front wheels, but appropriate

�

Lotus wheels for the rear weren't available so instead they used Brabham four stud 13x8.5 wheels.

�

(The currently-installed wheels don't accurately represent what BRP used in either 1963 or 1964.)

�

�

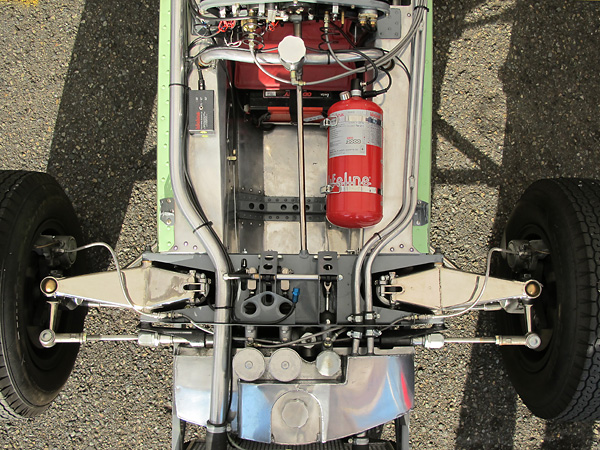

Interior

��

�

The cozy cockpit of the BRP-BRM Formula One racecar.

�

�

Leather covered steering wheel.

�

�

This RaceTech quick release steering wheel hub is a modern era innovation, and an important

�

safety feature. Before it was installed, getting into or out of the car was a contortionist's act.

�

�

Left to right: Racetech dual fuel pressure (0-160psi) / coolant temperature (30-120C) gauge, Smiths

�

tachometer (0-12500rpm), and Racetech dual oil pressure (0-160psi) / oil temperature gauge (30-120C).

�

�

Odyssey Extreme Racing 30 battery (part number 9750M6746, AGM, 20.0lb, 450CCA).

�

�

A stiff steel brace helps transfer suspension loads across the floor panel. Although the tub's

�

main panels are aluminum, bulkheads and baffles and brackets were mainly fabricated from

�

18 and 19 gage mild steel

�

�

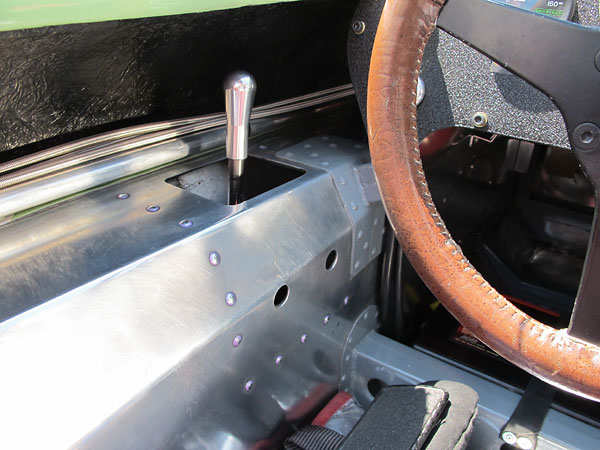

Six speeds forward selected from a double-H pattern, but no reverse gear.

�

�

Number 9 car has a shifter plate whereas number 41 doesn't, but they have identical levers and knobs.

�

�

Willans six point cam-lock safety harness.

�

�

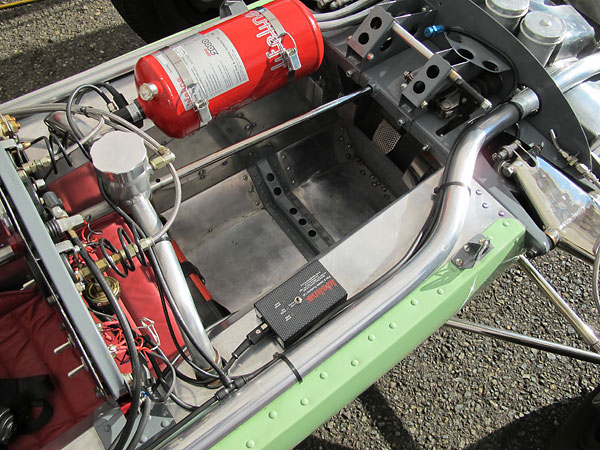

Lifeline Zero 2000 centralized fire suppression system.

�

�

The fuel filler is only accessible for refueling when fiberglass bodywork is removed for access.

�

Foreground: electronic control module for the Lifeline fire suppression system.

�

�

The BRP-BRMs were originally built with three Maston-Excelsior rubber fuel bladders - two in the

�

pontoons plus a 4.5 gallon cell under the seat - for a combined capacity of ~27.5 gallons. As

�

prepared for vintage racing, smaller dual fuel bladders provide this car a capacity of ~14 gallons.

�

Fuel economy? These cars burn about six gallons per half hour session.

�

�

A late model Lucas electronic ignition box is now hidden under the seat, along with a rev limiter.

�

There's also some fuel plumbing, and access to the oil filter.

�

�

Modern tall roll hoop with formed sheetmetal headrest bar and rearward brace. (The original

�

BRP-BRM racecars had lower hoops with tubular crossbraces, and no rearward braces.)

�

�

Exterior

��

�

Byron Sanborn holds an umbrella for Kurt DelBene as the pre-grid fills.

�

(at the 2011 Pacific Northwest Historics, Pacific Raceways in Kent, Washington.)

�

�

The BRP-BRM was the second car of Formula One's new generation to feature monocoque

�

construction. That it was developed so quickly and proved both reliable and quick right out of

�

the box is a tremendous credit to the small, well coordinated team which pulled together to build it.

�

�

In the BRP-BRM's era, the entire Formula One field ran on Dunlop R6 tires. In 1963, R6s had

�

a taller aspect ratio than they did in 1964. Racing on L-section tires, 1.5L F1 cars had less

�

grip than even late sixties era Formula Fords.

�

�

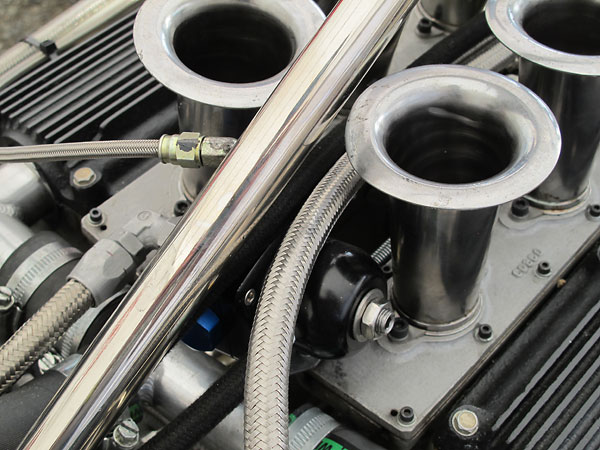

Easiest way to tell a BRP-BRM from a Lotus 25 at high speed? The velocity stacks on the BRP

�

fitt neatly under the engine cover. The Lotus, with its Climax engine, used taller stacks.

�

�

British Racing Partnership's team cars were some of the most recognizeable of their era because of

�

their distinctive "meadow green" paint color. The color was selected by team co-owner Alfred Moss.

�

�

Alfred Moss (Stirling's dad) had been a racing driver in his own right. His first notable victory was in

�

the Private Competitors' Handicap race during the 1923 Easter meeting at Brooklands. His car was a

�

Sporting Crouch powered by an Anzani four cylinder engine. In it, he averaged about 65mph. Just

�

one year later he managed to secure a seat for the Indianapolis 500, where he piloted one of three

�

Barber-Warnock sponsored racecars for Louis Chevrolet's team to a 16th place finish at 84mph.

�

�

BRP's departure from Grand Prix racing was assured in 1964 when the team was blackballed by Lotus

�

Ferrari, and ultimately BRM in their attempt to join the Formula One Constructors Association. Although

�

Cooper and Brabham supported BRP's bid for membership, the other three member companies blocked

�

BRP's application on grounds that they weren't producing enough of the car's they raced. Membership in

�

FOCA had become hugely important that year because the organization had used its collective leverage

�

to negotiate new starting money agreements with the various race organizers. For non-members,

�

starting money dropped to a level that made BRP's continued participation far less attractive.

�

�

After leaving Formula One, British Racing Partnership accepted a commission to design and build

�

two final cars... for the Indianapolis 500! The commission came from George R. Bryant, stepfather of

�

driver Masten Gregory. BRP's Indy project started in February 1965 and the resulting two cars were

�

delivered to Indianapolis in early May. Tony Robinson deserves full credit for their design; fabrication

�

was assisted by Jim Chapman, George Woodward, Stan Collier, Bruce McIntosh and Peter Downie.

�

At Indy, Howard Gilbert & George Salih installed Ford quad cam engines and ZF 5DS-25 transaxles.

�

�

The BRP Indy cars proved competitive over a long three-year career. Poor luck in qualifying set the

�

stage for an exciting 1965 race: Masten Gregory started 31st of 33 in car number 41 (serial 65/1). From

�

the back of the pack, Gregory drove brilliantly and climbed to fourth place before a loss of oil pressure

�

on lap 59 of 200 forced him to retire for a 23rd-place finish. Johnny Boyd started 29th and completed

�

140 laps before a gearbox failure forced him to retire for a 13th-place finish. Two years later at the 1967

�

Indy 500, Carl Williams started the number 41 car from 23rd position, yet worked his way up through

�

the field and was running third on the race's final lap when he got tied up in an accident. Conclusion:

�

BRP didn't design or build many racecars, but their expertise in these disciplines was considerable.

�

| Notes: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (1) | �

In 1963, Jim Clark won the Formula One championship easily with his Climax V8 powered Lotus 25.�

In addition to the ten race championship season, there were fourteen non-championship F1 races in 1963.�

When BRP's drivers entered these races, they used the team's Lotus 24s, with just one notable exception.�

Innes Ireland drove his BRP-BRM at the Solitude Grand Prix near Stuttgart on July 28. He finished third.�

� | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (2) | �

In 1964, John Surtees won the Formula One championship by just one point with his V8 powered Ferrari.�

In addition to the ten race championship season, there were also eight non-championship�

F1 races in 1964 and BRP contested six of these.�

Ireland won the first one! It was the Daily Mirror Trophy at Snetterton.�

Ireland had an accident in the second one: the News of the World Trophy at Goodwood.�

Ireland and Taylor both retired their BRPs early at the Aintree 200,�

Ireland with a suspension failure and Taylor with an engine problem.�

Ireland had a bad accident at Silverstone in the BRDC International Trophy race, and Taylor retired with low oil pressure.�

Ireland also had an accident at Solitude.�

Ireland finished third in the Mediterranean Grand Prix at Sicily, but Taylor suffered a suspension trailing link failure.�

(In two other non-championship F1 races, Taylor drove the team's leftover Lotus 24.)�

� | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (3) | �

The BRP-BRM's One Victory� Daily Mirror Trophy, Snetterton, 14 March 1964�

� | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (4) | �

BRP-BRM 64/2 Results after being Rebuilt for Formula 5000� Guards F5000 Championship:�

� The Tasman Series: �

�  � Kaye Griffiths' attempt to qualify for the 19th Lady Wigram Trophy race comes to an abrupt end. � (Photographer unknown. This photo appeared in Shell Oil's "1970 New Zealand Motor Racing".) � � | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (5) | �

It isn't clear exactly how or when chassis 64/2 was re-united with BRM rengine or transaxle as described�

by Ferris de Joux. Both he and Peter Bruin have passed away, so we were unable to check that detail. �

� | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

�

�

We wish to gratefully acknowledge all the people who provided information and assistance with this article,�

including especially Ken Gregory and Tony Robinson who gave interviews and also Byron Sanborn of Vintage�

Racing Motors of Redmond Washington who walked us around the car and helped us understand what we�

were looking at. Thor Thorson of Vintage Racing Motors and racing writer/biographer Ian Wagstaff were also�

extremely generous with their assistance. �

�

Unless otherwise noted, all photos shown here are from June 2011 when we viewed the car at�

The Pacific Northwest Historics at Pacific Raceways in Kent, Washington.�

All photos by Curtis Jacobson for BritishRaceCar.com,�

copyright 2011. All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Jay Nadelson 1957 Cooper T43 | �

| �

Marcus Jones 1960 Lotus 18 Junior | �

| �

Eric Haga 1970 Lola T190 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�